Oil absorbing cotton

A technology for absorbing cotton and oil flowers, which is applied in the direction of filtration and separation, membrane filter, layered products, etc. It can solve the problems of low carburetion efficiency, high toxicity of dispersant, waste of oil dispersant, etc., and solve oil spill accidents , Improve fishing efficiency, improve the effect of water and oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

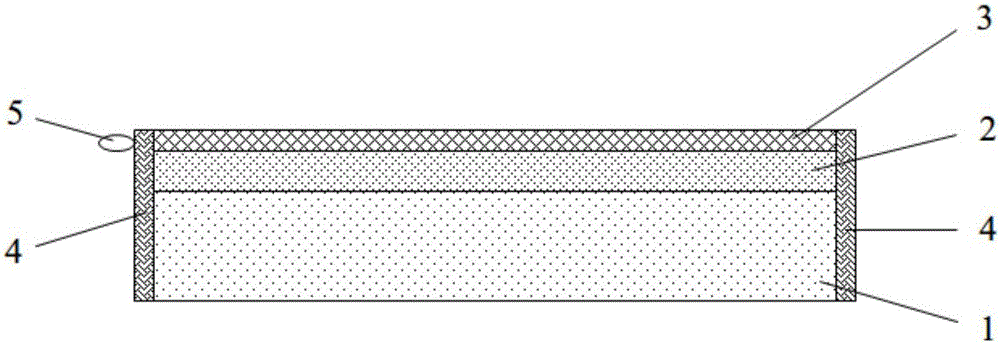

[0031] The present invention provides an oil-flower absorbent cotton. The absorbent cotton includes an oil-absorbing layer 1, a hydrophilic oil-absorbing layer 2, a filter screen 3, a reinforcement layer 4, and connecting ears. The hydrophilic oil-absorbing layer 2 is formed on the oil-absorbing layer 1. The oil-absorbing layer 1 is made of viscose fiber and oil-absorbing polymer fiber blended, and the hydrophilic oil-absorbing layer 2 is made of a hydrophilic material and an oil-absorbing material blended.

[0032] The viscose fiber and the oil-absorbing polymer fiber are mixed in a ratio of 1:1-3, and the hydrophilic material and the oil-absorbing material are mixed in a ratio of 5-8:1.

[0033] The viscose fiber includes filaments and short filaments, and the ratio of the filaments to the short filaments of the viscose fiber is 1-10:1;

[0034] The oil-absorbing polymer fibers include filaments and short filaments, and the ratio of the filaments to the short filaments of the oil-a...

Embodiment 2

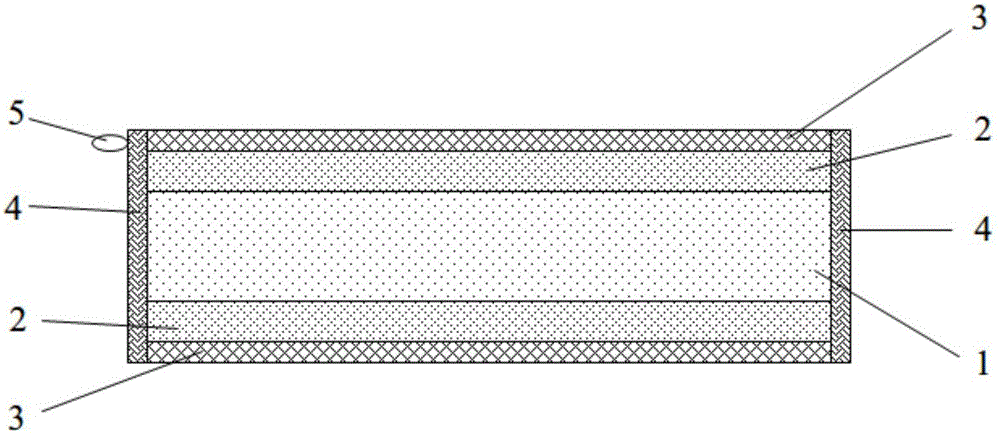

[0045] The present invention provides an oil-flower absorbent cotton. The absorbent cotton includes an oil-absorbing layer 1 and a hydrophilic oil-absorbing layer 2. The hydrophilic oil-absorbing layer 2 wraps the oil-absorbing layer 1.

[0046] The oil-absorbing layer 1 is made of a blend of viscose fiber and an oil-absorbing polymer fiber, and the hydrophilic oil-absorbing layer 2 is made of a blend of a hydrophilic material and an oil-absorbing material.

[0047] The viscose fiber and the oil-absorbing polymer fiber are mixed in a ratio of 1:1-3, and the hydrophilic material and the oil-absorbing material are mixed in a ratio of 5-8:1.

[0048] The viscose fiber includes filaments and short filaments, and the ratio of the filaments to the short filaments of the viscose fiber is 1-10:1;

[0049] The oil-absorbing polymer fibers include filaments and short filaments, and the ratio of the filaments to the short filaments of the oil-absorbing polymer fibers is 5-10:1.

[0050] The oil ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com