A kind of synthetic method of all silicon beta molecular sieve

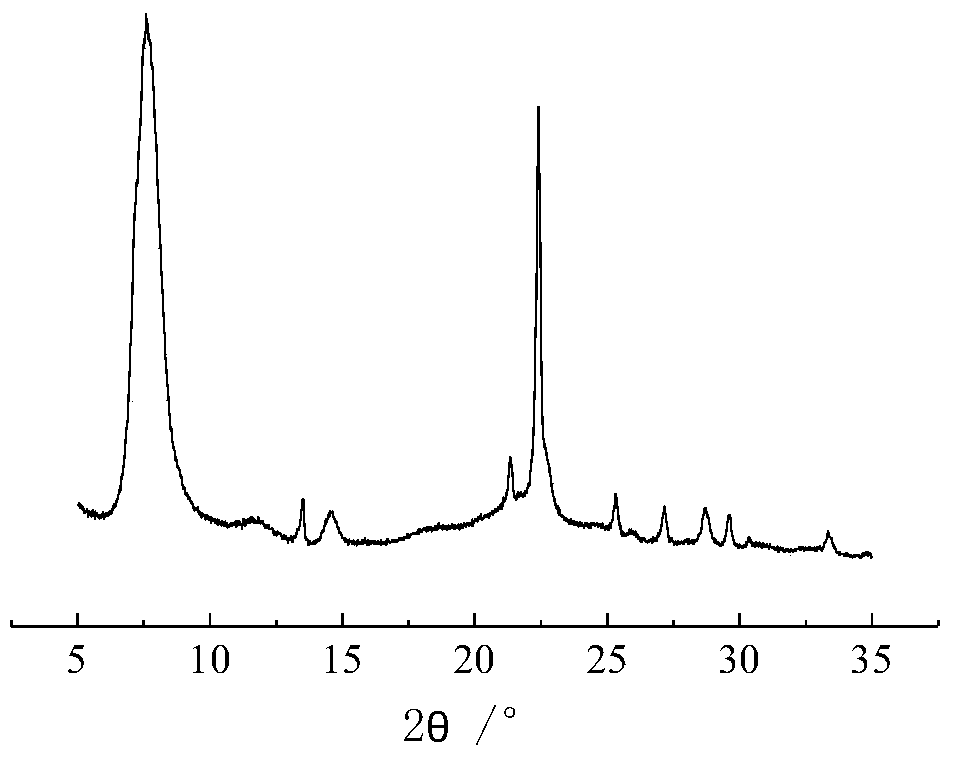

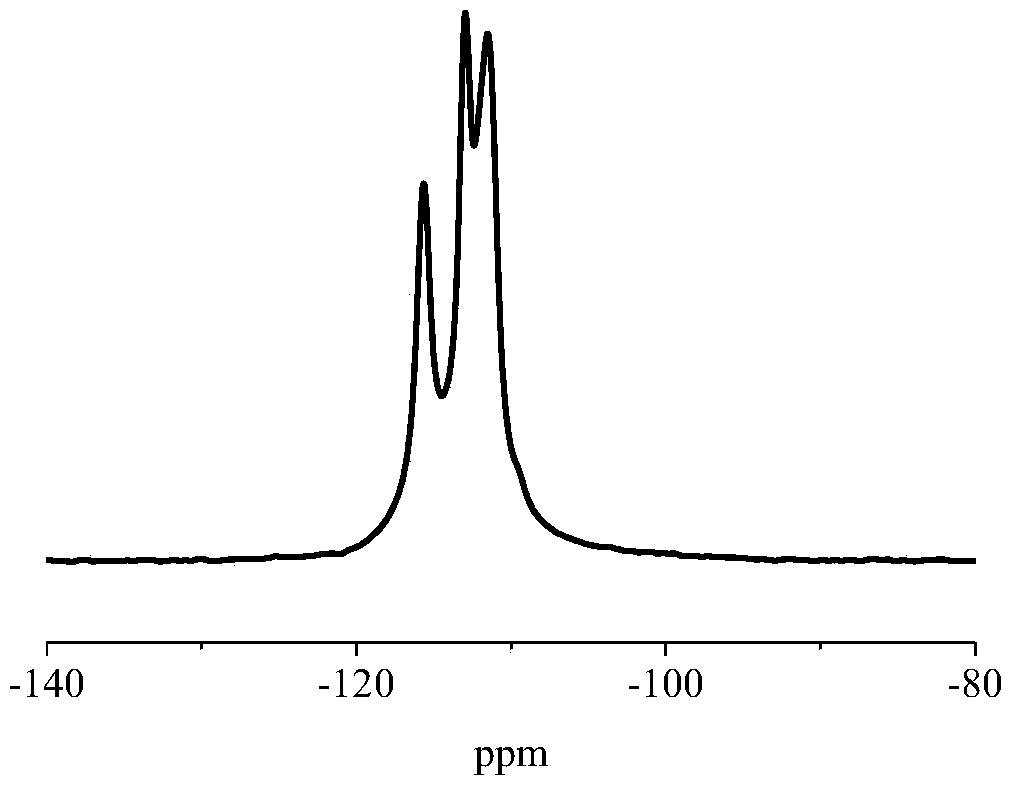

A synthesis method and molecular sieve technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of large particles, many skeleton defects, unsuitable for promotion and use, etc., and achieve the effect of small particles and fewer skeleton defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a kind of synthetic method of all-silicon beta molecular sieve, comprising the following steps:

[0034] (1) Mix the silicon source, fluorine-containing mineralizer, water, templating agent and optional alkali source evenly to obtain a molar ratio of OH - :SiO2 2 :F:R:H 2 The reaction mixture of O=(0.21-4):1:(0.1-5):(0.4-5):(2-50); wherein F represents the molar number of fluorine atoms in the reaction mixture, which includes the The F contained also includes the F that may be contained in other added raw materials such as the templating agent or the alkali source; R represents the molar number of the templating agent;

[0035] (2) Transfer the reaction mixture obtained in step (1) to a pressure-resistant airtight container, and crystallize at a temperature of 80-200° C. and an autogenous pressure for 0.5-30 days to obtain a crystallized product;

[0036] (3) recovering the crystallized product obtained in step (2).

[0037] According to the p...

Embodiment 1

[0056] by SiO 2 : TEAOH = 1:0.54 molar ratio, then add a certain amount of water, under the stirring condition of 600r / min, mix ethyl orthosilicate, deionized water and tetraethylammonium hydroxide, and in 70 ℃ Hydrolyzed for 10 hours at a certain temperature to obtain a clear hydrolyzed solution of ethyl orthosilicate. Then under the stirring condition of 1000r / min, according to F: SiO 2 =0.5:1 molar ratio, add sodium fluoride and hydrofluoric acid in tetraethyl orthosilicate hydrolysis solution, obtain H after stirring evenly 2 O:OH - :SiO2 2 = 7.25:0.5:1 mixture.

[0057] The mixture was transferred to a closed pressure-resistant container, and under the stirring condition of 400r / min, the temperature of the crystallization system was raised to 140°C, and the temperature was kept at autogenous pressure for 10 days to obtain a mixture of crystallized products; the mixture was filtered, Washing with water until the pH is between 6 and 8; drying at a temperature of 110°C ...

Embodiment 2

[0059] by SiO 2:TEACl:NaOH=1:0.8:0.8 molar ratio, then add a certain amount of water, under the stirring condition of 300r / min, mix ethyl orthosilicate, deionized water, sodium hydroxide and tetraethyl chloride Ammonium chloride was mixed and hydrolyzed at 30°C for 20 hours to obtain a hydrolysis solution of ethyl orthosilicate. Then under the stirring condition of 100r / min, according to F: SiO 2 =0.2:1 molar ratio, add hydrofluoric acid in tetraethyl orthosilicate hydrolysis solution, obtain H after stirring 2 O:OH - :SiO2 2 = 10:0.6:1 mixture.

[0060] The mixture was transferred to a closed pressure-resistant container, and under the stirring condition of 800r / min, the temperature of the crystallization system was raised to 150°C, and the temperature was kept at autogenous pressure for 7 days to obtain a mixture of crystallization products; the mixture was filtered, Wash with water until the pH is between 6 and 8; dry at 130°C for 4 hours, and grind the dried mixture e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com