A kind of ti-beta molecular sieve and its synthetic method and application

A molecular sieve and reaction technology, which is applied in the field of Ti-beta molecular sieve and its synthesis, can solve the problems of reduced selective oxidation activity, too large Ti-β particles, and difficult synthesis, and achieve small particle size, few skeleton defects, and good catalysis performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] On the other hand, the present invention also provides a synthesis method of Ti-beta molecular sieve, including the following steps:

[0030] (1) Mix the silicon source, titanium source, mineralizer, structure directing agent, water and optional alkali source uniformly to obtain a molar ratio of OH - : SiO 2 :TiO 2 : A: R: H 2 O=(0.15-3):1:(0.001-0.1):(0.001-5):(0.3-5):(3-300) reaction mixture; wherein, the structure directing agent is selected from tetraethyl At least one of ammonium hydroxide, tetraethylammonium fluoride, tetraethylammonium chloride, tetraethylammonium bromide, tetraethylammonium iodide, diethylamine and triethylamine, the mineral The agent is a mixture containing at least one halide ion compound and at least one alkali metal compound; A represents the number of moles of mineralizer in the reaction mixture, and R represents the number of moles of structure directing agent in the reaction mixture;

[0031] (2) Crystallize the reaction mixture obtained in st...

Embodiment 1

[0058] Under stirring conditions, mix ethyl orthosilicate, tetrabutyl titanate, tetraethylammonium hydroxide and deionized water at 60℃ to obtain SiO 2 :TiO 2 : Structure Directing Agent: H 2 O=1:0.02:1.1:20 alkaline mixed solution, then according to mineralizer: SiO 2 =0.6, the molar ratio of hydrofluoric acid: sodium chloride = 1.2, add mineralizer to the alkaline mixture and stir to obtain OH - :SiO 2 =0.77 Ti-β molecular sieve precursor.

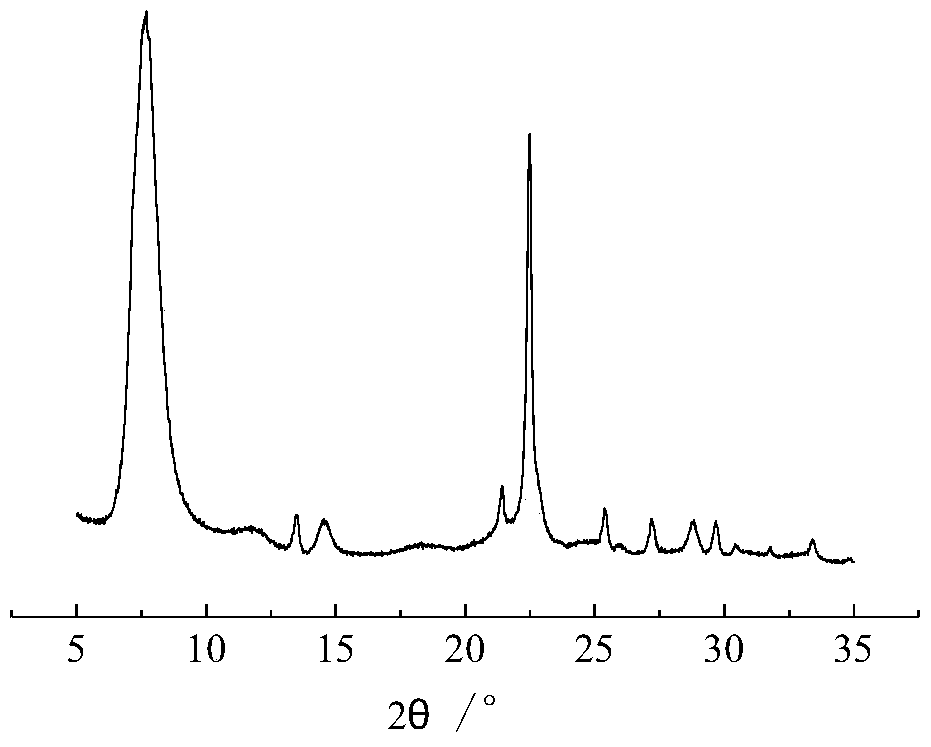

[0059] After transferring the colloid to a pressure-resistant closed reactor, under agitation, the crystallization system was heated to 135°C and kept constant at autogenous pressure for 10 days to obtain a mixture of crystalline products; this mixture was filtered and washed with water. After all; drying at 110° C. for 8 hours and then roasting at 550° C. for 4 hours to obtain Ti-β molecular sieve. The XRD spectrum of the molecular sieve is as follows figure 1 As shown, the topography of the scanning electron microscope (SEM) is as figure ...

Embodiment 2

[0061] Under stirring conditions, mix methyl orthosilicate, tetrapropyl titanate, tetraethylammonium fluoride, deionized water and external alkali source sodium carbonate at 40°C to obtain SiO 2 :TiO 2 : Structure Directing Agent: H 2 O=1:0.01:0.4:5 alkaline mixed solution, and then according to mineralizer: SiO 2 =0.01, fluorosilicic acid: sodium fluoride = 0.5 molar ratio, add mineralizer to the alkaline mixture and stir to obtain OH - :SiO 2 = 0.4 Ti-β molecular sieve precursor.

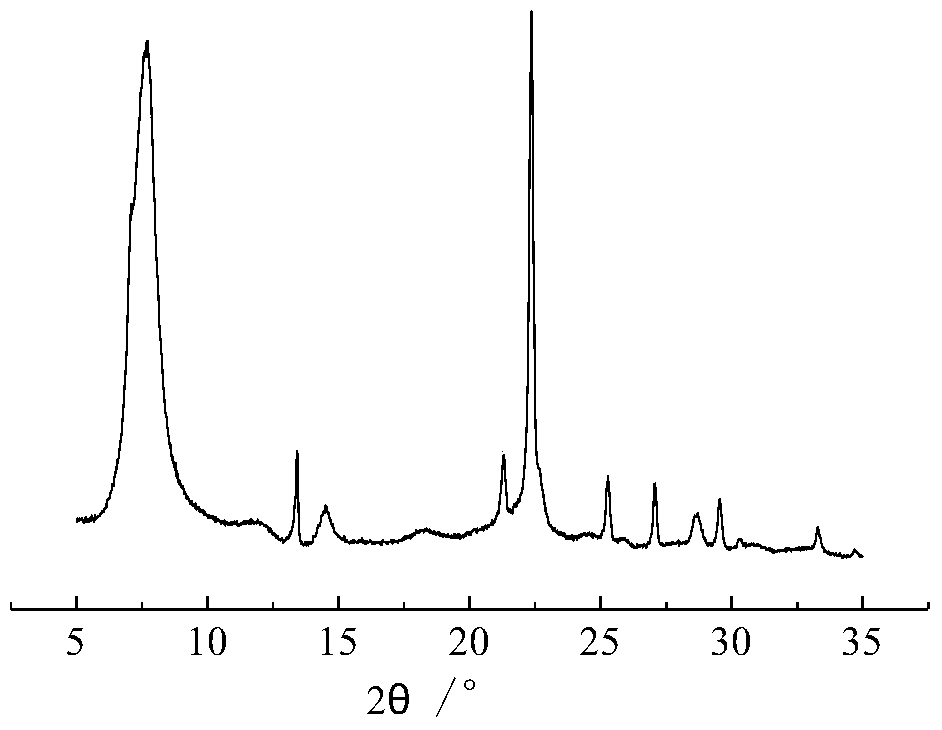

[0062] After transferring the colloid to a pressure-resistant closed reactor, under stirring, the crystallization system was heated to 120°C and kept at a constant temperature under autogenous pressure for 25 days to obtain a mixture of crystalline products; this mixture was filtered and washed with water. After all; drying at a temperature of 90°C for 12h and then calcining at a temperature of 450°C for 10h to obtain Ti-β molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com