Nanometer sn-β molecular sieve and its preparation method and the method of phenol hydroxylation reaction

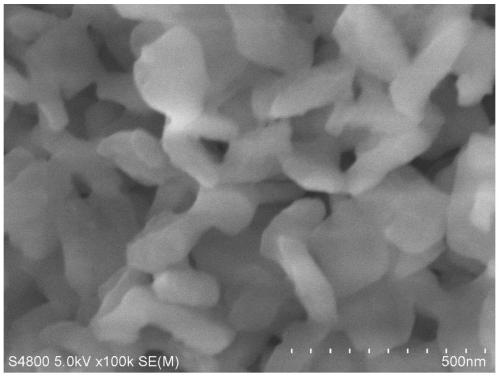

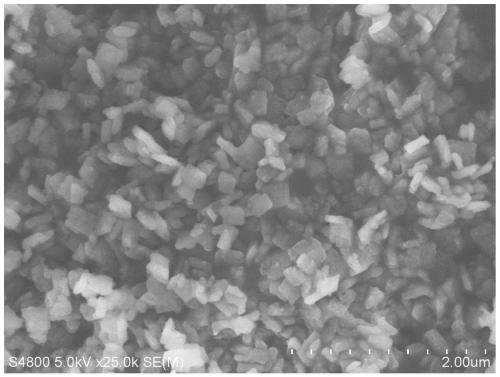

A beta molecular sieve and molecular sieve technology, applied in the field of beta molecular sieve, can solve the problems of easy deep oxidation, etc., and achieve the effect of less skeleton defects, large specific surface area and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of nanometer Sn-beta molecular sieve, comprises the following steps:

[0026] (1) In the presence of an aqueous solvent, mix the silicon source, the tin source, the structure-directing agent and the alkali source in proportion to obtain a gel-like mixed solution, adjust the pH value of the mixed solution to 9.5-13.8, and place the mixed solution in Crystallize at a temperature of 150-220°C for 5-28 days, separate and roast to obtain a crystallized product;

[0027] (2) mixing the crystallization product, cobalt salt and / or nickel salt in an aqueous solvent in proportion to obtain a reaction solution, and reacting the reaction solution at a temperature of 180-220° C. for 2-10 hours to obtain a molecular sieve precursor;

[0028] (3) mixing the molecular sieve precursor and the sulfur-containing medium in a water-containing solvent, and reacting at a temperature of 80-140° C. for 1-6 hours to obtain nano Sn-β molecular s...

Embodiment 1

[0058] Under stirring conditions, tetraethyl orthosilicate, sodium stannate, tetraethylammonium hydroxide and hydrazine hydrate are mixed in water, and the molar ratio of each substance in the formed mixed solution is SiO 2 :Sn:Structure directing agent:H 2 O=1:0.012:1.3:100, stir until the solution is gel, add potassium tert-butoxide to adjust the pH value of the solution to 12.6, then transfer the solution to a polytetrafluoroethylene reactor, the total volume of the mixed solution is 65% of the capacity of the reactor, crystallized at a temperature of 190°C for 5 days, separated and roasted to obtain a crystallized product;

[0059] The crystallization product, cobalt sulfate, and nickel nitrate are in weight ratio: crystallization product: Co 2+ : Ni 2+ = 1:1:1 dissolved in water to obtain a mixed solution, transfer the mixed solution into a polytetrafluoroethylene reactor, react at a temperature of 180°C for 10 hours, and obtain a pink precursor; add the precursor to so...

Embodiment 2

[0062] Under stirring conditions, tetraethoxysilane, tin sulfate, tetraethylammonium iodide and sodium ethylate are mixed in water, and the molar ratio of each substance in the formed mixed solution is SiO 2 :Sn:Structure directing agent:H 2 O=1:0.01:1.0:10, stir until the solution is gel-like, add ammonia water to adjust the pH value of the solution to 11.7, then transfer the solution into a polytetrafluoroethylene reactor, the total volume of the mixed solution is the capacity of the reactor 65%, crystallized at 180°C for 10 days, separated and roasted to obtain a crystallized product;

[0063] The crystallization product, cobalt nitrate, and nickel sulfate are in weight ratio: crystallization product: Co 2+ : Ni 2+ =1:0.5:1.5 dissolved in water to obtain a mixed solution, transfer the mixed solution into a polytetrafluoroethylene reactor, and react at a temperature of 190°C for 4 hours to obtain a pink precursor; add the precursor to thiourea In the aqueous solution, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com