Ti-beta molecular sieve and synthesis method and application thereof

A molecular sieve and reaction technology, applied in the field of Ti-beta molecular sieve and its synthesis, can solve the problems of reduced selective oxidation activity, too large Ti-β particles, complex structure, etc., and achieve small particle size, few skeleton defects and good catalysis performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] On the other hand, the present invention also provides a kind of synthetic method of Ti-beta molecular sieve, comprises the following steps:

[0030] (1) Mix the silicon source, titanium source, mineralizer, structure-directing agent, water and optional alkali source evenly to obtain a molar ratio of OH - : SiO 2 : TiO 2 :A:R:H 2 O=(0.15-3):1:(0.001-0.1):(0.001-5):(0.3-5):(3-300) reaction mixture; wherein, the structure directing agent is selected from tetraethyl At least one of ammonium hydroxide, tetraethylammonium fluoride, tetraethylammonium chloride, tetraethylammonium bromide, tetraethylammonium iodide, diethylamine and triethylamine, the mineral The mineralizing agent is a mixture containing at least one halogen ion compound and at least one alkali metal compound; A represents the molar number of the mineralizing agent in the reaction mixture, and R represents the molar number of the structure-directing agent in the reaction mixture;

[0031] (2) crystallize th...

Embodiment 1

[0058] Under stirring conditions, ethyl orthosilicate, tetrabutyl titanate, tetraethylammonium hydroxide and deionized water were mixed at 60 °C to obtain SiO 2 :TiO 2 : Structure directing agent: H 2 Alkaline mixed solution of O=1:0.02:1.1:20, then mineralizer: SiO 2 = 0.6, hydrofluoric acid: sodium chloride = 1.2 molar ratio, mineralizer is added to the alkaline mixture and stirred evenly to obtain OH - :SiO2 2 =0.77 Ti-beta molecular sieve precursor.

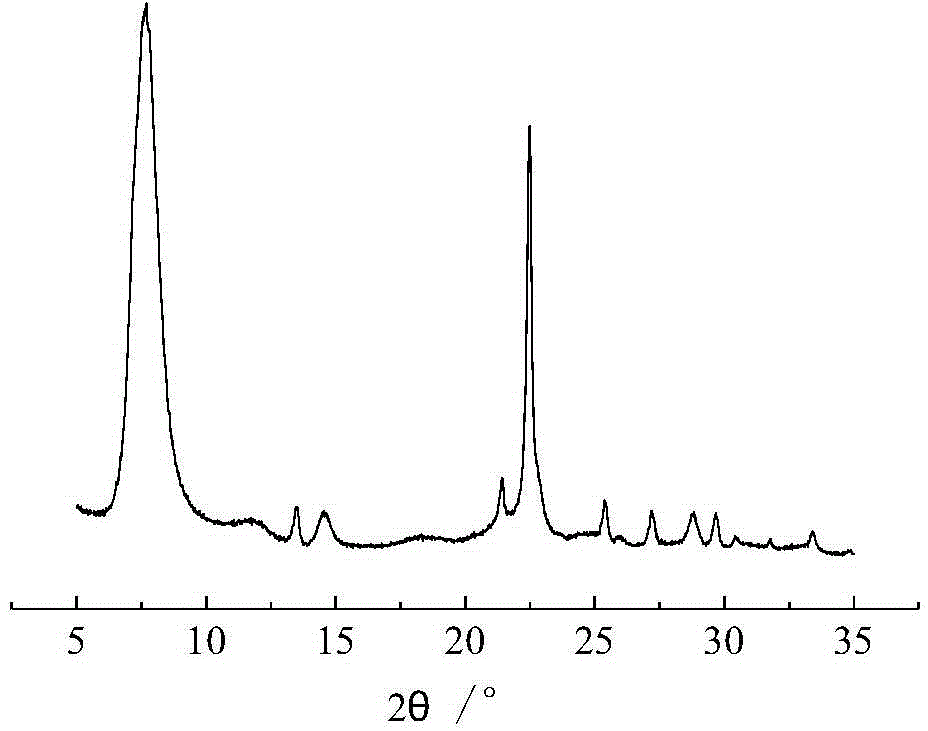

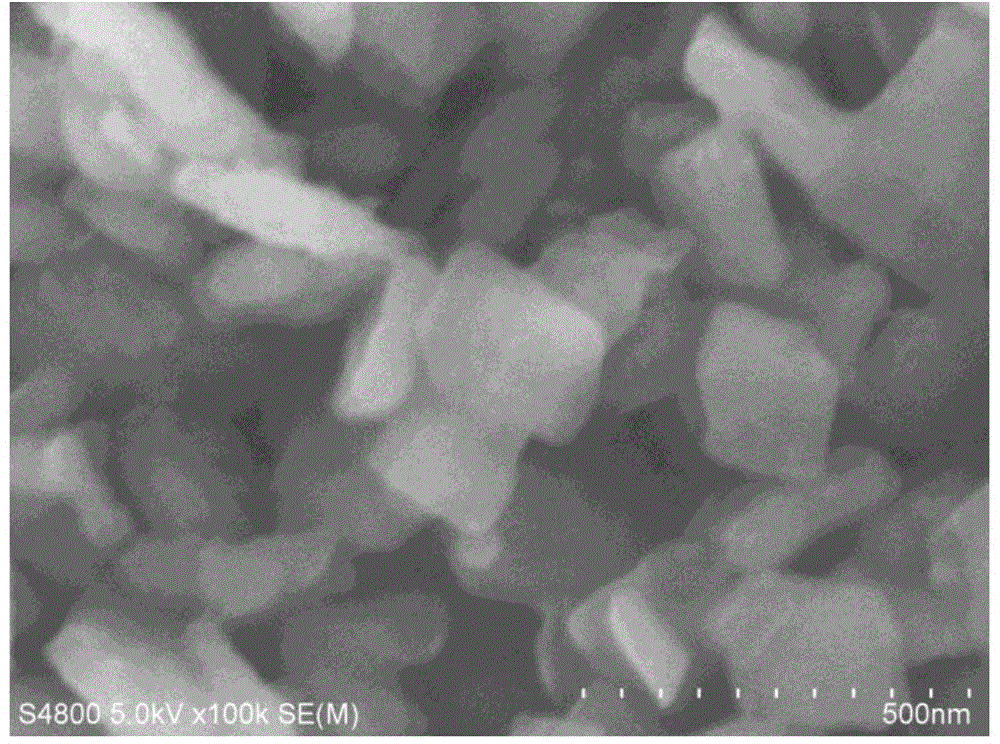

[0059] After transferring the colloid to a pressure-resistant closed reactor, the temperature of the crystallization system was raised to 135°C under stirring conditions, and the temperature was kept at autogenous pressure for 10 days to obtain a mixture of crystallization products; the mixture was filtered and washed with water for several After one pass; drying at a temperature of 110°C for 8 hours and then calcining at a temperature of 550°C for 4 hours to obtain a Ti-β molecular sieve. The XRD spectrum of the molecul...

Embodiment 2

[0061] Under stirring conditions, mix methyl orthosilicate, tetrapropyl titanate, tetraethylammonium fluoride, deionized water and external alkali source sodium carbonate at 40°C to obtain SiO 2 :TiO 2 : Structure directing agent: H 2 Alkaline mixed solution of O=1:0.01:0.4:5, then mineralizer: SiO 2 =0.01, fluorosilicic acid: sodium fluoride = 0.5 molar ratio, add mineralizer to the alkaline mixture and stir evenly to obtain OH - :SiO2 2 =0.4 Ti-beta molecular sieve precursor.

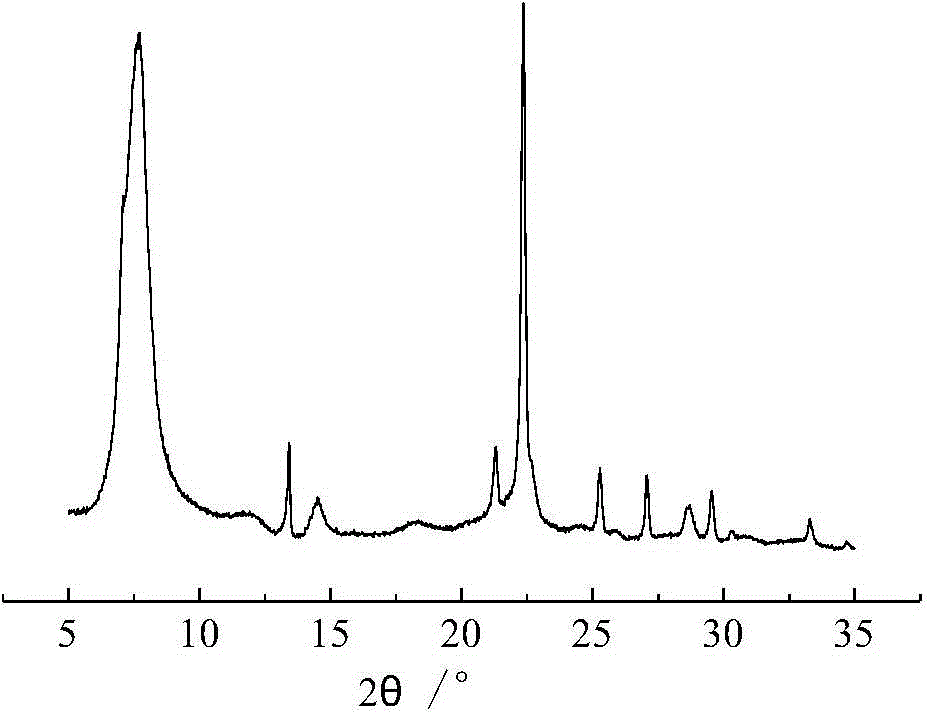

[0062] After transferring the colloid to a pressure-resistant closed reactor, the temperature of the crystallization system was raised to 120°C under stirring conditions, and the temperature was kept at autogenous pressure for 25 days to obtain a mixture of crystallization products; the mixture was filtered and washed with water for several After one pass; drying at 90° C. for 12 hours and then calcination at 450° C. for 10 hours to obtain Ti-β molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com