Preparation method for alpha-FeOOH three-dimensional multi-grade microsphere

A microsphere, three-dimensional technology, applied in the direction of iron oxide/iron hydroxide, etc., can solve the problem of long time consumption, and achieve the effect of simple preparation process, low reaction temperature and controllable microscopic shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this example, first add 0.261g FeSO to 40mL deionized water 4 ·7H 2 O and 0.015g CH 3 COONa, stirred and dissolved to obtain a reaction solution, then put the reaction solution into a 50mL polytetrafluoroethylene hydrothermal reaction kettle, kept it at 120°C for 2 hours, then cooled to room temperature to obtain a reaction solution; then centrifuged the obtained reaction solution, and used it in turn Ionized water and ethanol were washed three times respectively to obtain a light yellow product, and finally the light yellow product was dried at 60° C. for 12 hours to prepare α-FeOOH three-dimensional multi-level microspheres.

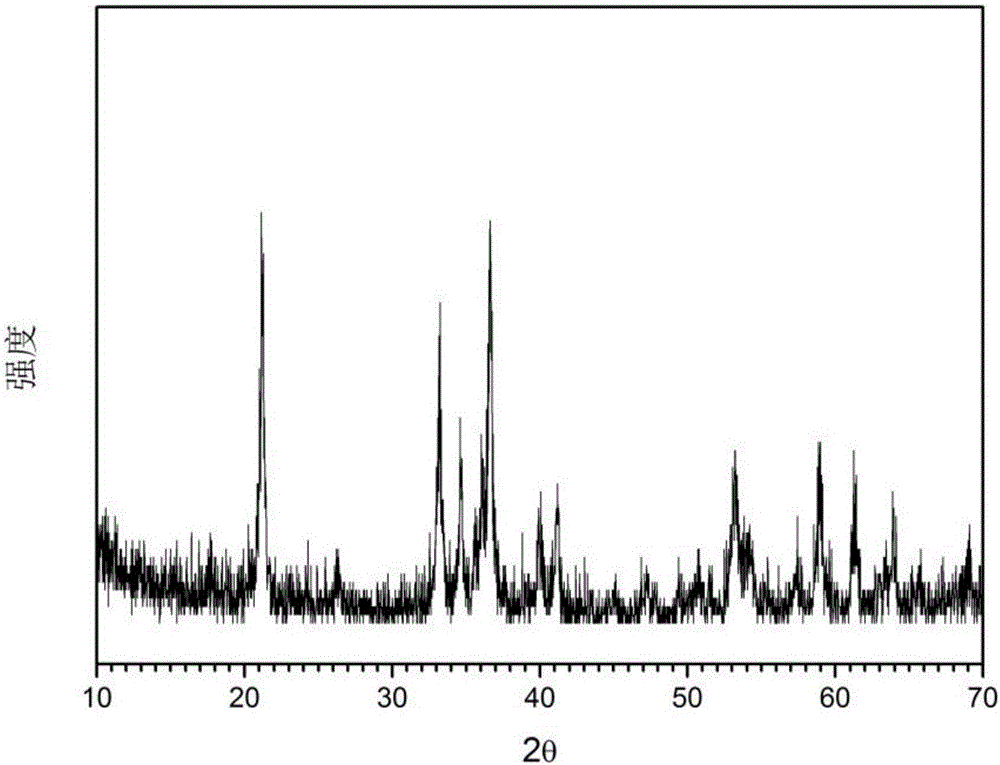

[0020] In this embodiment, the product α-FeOOH three-dimensional multi-level microspheres are characterized by XRD, as shown in figure 1 As shown, the sample phase is orthorhombic goethite α-FeOOH.

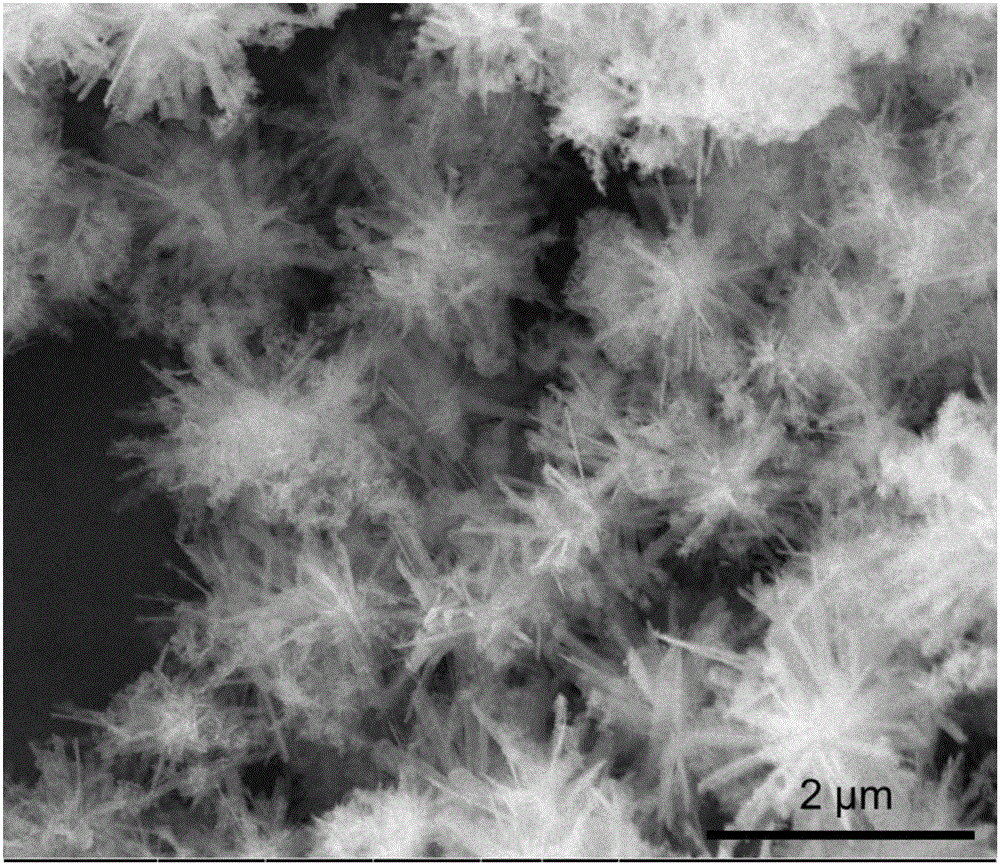

[0021] In this example, the product α-FeOOH three-dimensional multi-level microspheres were characterized by SEM, as figure 2 As shown, the...

Embodiment 2

[0023] In this example, first add 0.261g FeSO to 40mL deionized water 4 ·7H 2 O and 0.015g CH 3 COONa, stirring and dissolving to obtain a reaction solution, then put the reaction solution into a 50mL polytetrafluoroethylene hydrothermal reaction kettle, heat the reaction at 120°C for 6h, then cool to room temperature to obtain the reaction solution; then centrifuge the obtained reaction solution, and use Ionized water and ethanol were washed three times respectively to obtain a light yellow product, and finally the light yellow product was dried at 60° C. for 12 hours to prepare α-FeOOH three-dimensional multi-level microspheres.

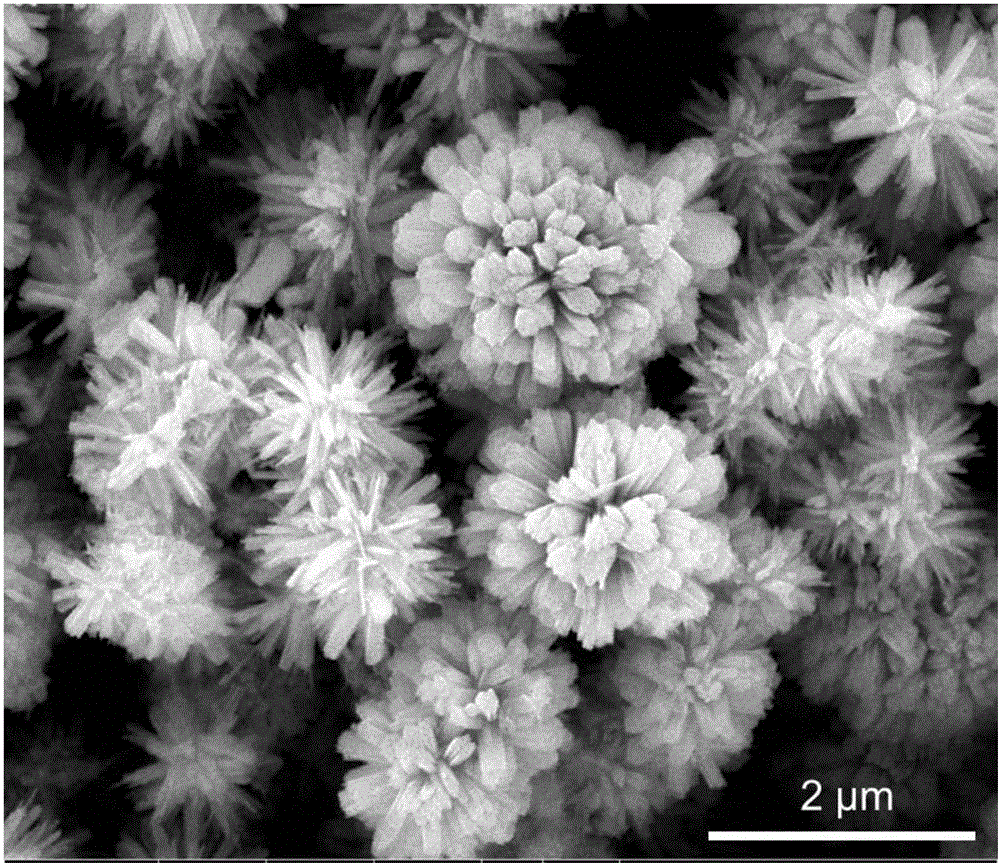

[0024] In this example, the product α-FeOOH three-dimensional multi-level microspheres were characterized by SEM, as image 3 As shown, the sample has a three-dimensional microsphere structure assembled by one-dimensional nanorods.

[0025] In this example, the obtained α-FeOOH three-dimensional multi-level microsphere structure was calcined at ...

Embodiment 3

[0027] In this example, 0.261g of FeSO was successively added to 40mL of deionized water 4 ·7H 2 O and 0.015g CH 3COONa, stirring and dissolving to obtain a reaction solution, then put the reaction solution into a 50mL polytetrafluoroethylene hydrothermal reaction kettle, keep the reaction at 120°C for 12h, then cool to room temperature to obtain the reaction solution; then centrifuge the obtained reaction solution, and use Wash with deionized water and ethanol three times respectively to obtain a light yellow product, and finally dry the light yellow product at 60° C. for 12 hours to obtain a three-dimensional multi-level microsphere structure of α-FeOOH.

[0028] In this example, the product α-FeOOH three-dimensional multi-level microspheres were characterized by SEM, as Figure 4 As shown, the sample has a three-dimensional microsphere structure assembled by one-dimensional nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com