Method for lowering bio-availability of Cu and Zn in pig manure based on biomass pyrolysis technology

A biomass pyrolysis and bioavailability technology is applied in the field of reducing the bioavailability of Cu and Zn in pig manure based on biomass pyrolysis technology. The effect of sufficient raw materials, environmental protection, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Optimization of pyrolysis temperature, pyrolysis time and pig manure chaff ratio

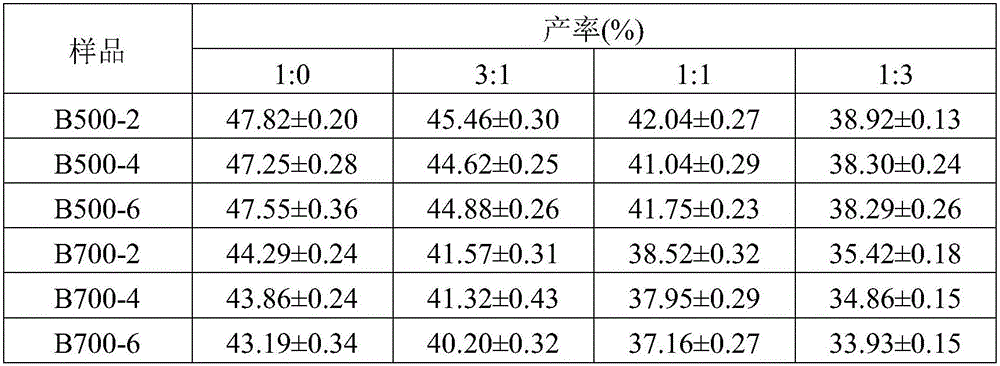

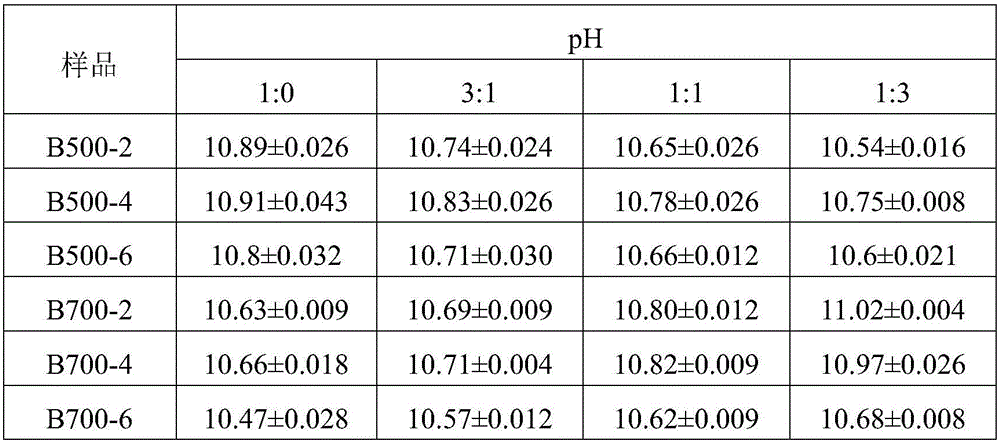

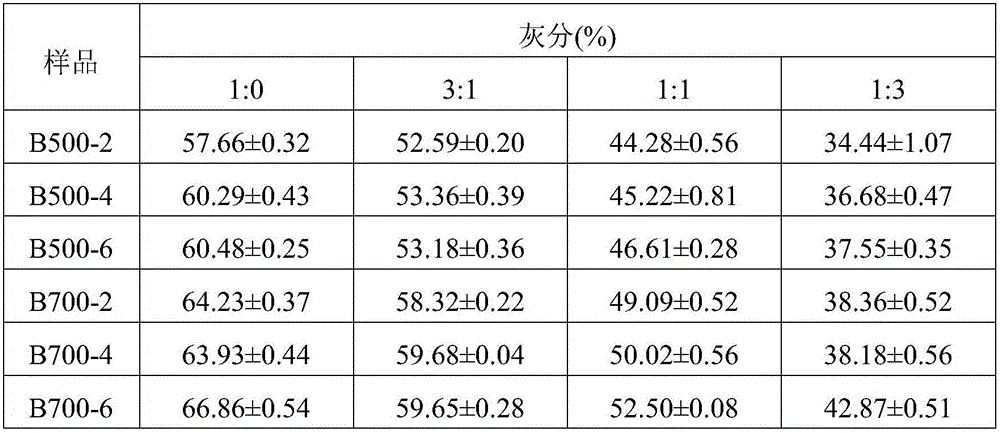

[0028] Dry the collected pig manure and chaff, remove impurities (remove gravel, hair, straw and other sundries), crush them and pass through a 20-mesh sieve; mix pig manure and chaff according to a certain ratio (1:0, 3:1, 1:1, 1:3), placed in an oven at 75°C and baked to constant weight, put 4 kinds of raw materials with different ratios into crucibles, filled and compacted, covered with a lid, placed in a crucible Furnace; heating rate is 20°C min -1 ; The final temperature is 500°C and 700°C; the holding time is 2h, 4h, and 6h; compare the yield, ash, pH, and heavy metal Cu of biochar under different pyrolysis temperatures, different pyrolysis times, and different raw material ratios And the total amount of Zn and its effective state content (see Table 1-6).

[0029] Table 1 Yields of biochar pyrolyzed for 2h, 4h, and 6h at 500°C and 700°C with different pig manure and cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com