Synthetic process of 1,2 difluoro-1,2 dichloroethylene

A dichloroethylene and synthesis process technology, applied in the chemical industry, can solve the problems of difficulty in stirring, difficult to handle the bottom material, easy agglomeration, etc., and achieve the effects of reducing unsafe factors, no potential safety hazards, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

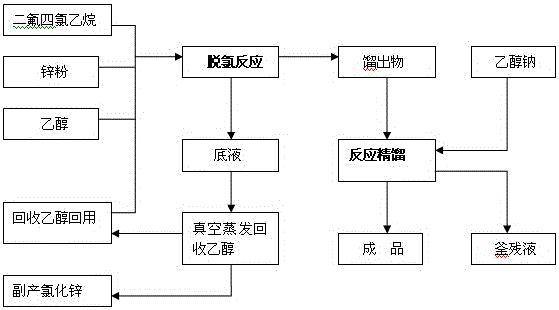

[0021] Such as figure 1 Shown, a kind of 1,2 difluorine-1,2 dichloroethylene synthesis technique comprises the steps:

[0022] The first step, dechlorination reaction: using difluorotetrachloroethane (R112) as raw material and zinc powder to carry out dechlorination reaction in the presence of ethanol to generate difluorodichloroethylene, the 10% zinc powder is passed through dilute acid Carry out activation, the order number of zinc powder is 50 orders, and reaction equation is as follows:

[0023] ;

[0024] In the first step, the dechlorination reaction, a batch process is adopted, and 204 g of difluorotetrachloroethane is added into the reaction kettle after being measured, and stirring is started, and zinc powder is added in a 1:1 mol ratio, and the temperature is raised to 20 ° C, slowly Slowly add ethanol to react, the ratio of ethanol is 1:2mol, control the reflux ratio well, take out the fraction after passing the test to the fraction tank, and gradually raise the...

specific Embodiment 2

[0028] Such as figure 1 Shown, a kind of 1,2 difluorine-1,2 dichloroethylene synthesis technique comprises the steps:

[0029] The first step, dechlorination reaction: using difluorotetrachloroethane (R112) as raw material and zinc powder to carry out dechlorination reaction in the presence of ethanol to generate difluorodichloroethylene, the 10% zinc powder is passed through dilute acid Carry out activation, the order number of zinc powder is 100 orders, and reaction equation is as follows:

[0030] ;

[0031] In the first step, the dechlorination reaction, a batch process is adopted, and difluorotetrachloroethane is added into the reaction kettle after metering, stirring is started, zinc powder is added in a ratio of 1:2mol, and the temperature is raised to 20°C-70°C , slowly add ethanol dropwise to react, the ratio of ethanol is 1:6mol, control the reflux ratio well, take out the distillate after passing the test to the distillate tank, and gradually raise the temperatu...

specific Embodiment 3

[0035] Such as figure 1 Shown, a kind of 1,2 difluorine-1,2 dichloroethylene synthesis technique comprises the steps:

[0036] The first step, dechlorination reaction: using difluorotetrachloroethane (R112) as raw material and zinc powder to carry out dechlorination reaction in the presence of ethanol to generate difluorodichloroethylene, the 10% zinc powder is passed through dilute acid Carry out activation, the order number of zinc powder is 80 orders, and reaction equation is as follows:

[0037] ;

[0038] In the first step, the dechlorination reaction, a batch process is adopted, and difluorotetrachloroethane is added into the reaction kettle after metering, stirring is started, zinc powder is added in a ratio of 1:1.5mol, and the temperature is raised to 20°C-70°C. ℃, slowly add ethanol dropwise for reaction, the ratio of ethanol is 1:3mol, control the reflux ratio well, take out the distillate after passing it to the distillate tank, and gradually raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com