A kind of synthetic method of paeonol and its structural analogs

A technology similar in structure to paeonol, which is applied in the field of synthesis of natural products, can solve the problems of inability to carry out biological activity testing and evaluation, chemical synthesis method reporting, etc., and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

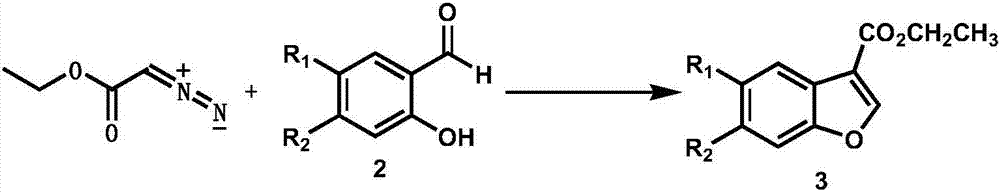

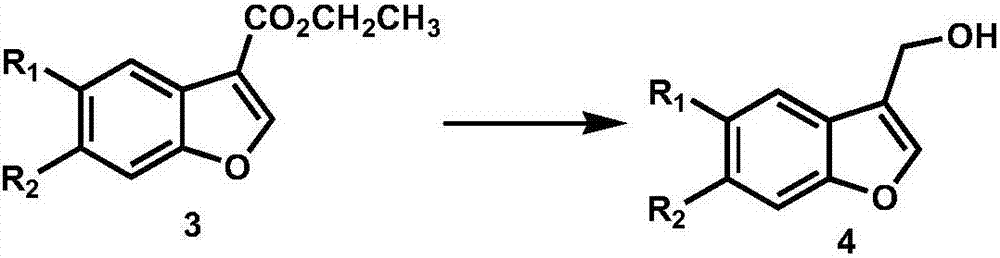

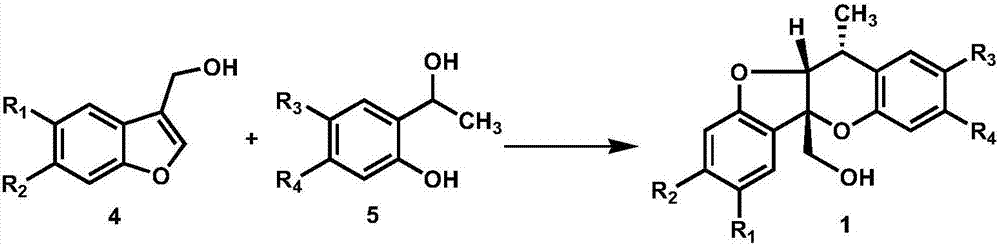

Method used

Image

Examples

Embodiment 1

[0017]

[0018] 1. Dissolve 3.2g (21mmol) of the salicylaldehyde derivative shown in formula 2-1 in 30mL of toluene and THF in a mixed solvent with a volume ratio of 1:1, cool the system to -78°C, add 3mL (90 %, 25mmol) ethyl diazoacetate, 0.4mL (50%, 0.21mmol) tetrafluoroborate ethyl ether complex, the system was slowly warmed up to room temperature, after 12 hours of reaction, the organic solvent was removed under reduced pressure, and added to the system 3mL of concentrated sulfuric acid, stirred for 1 hour, extracted with ethyl acetate, the organic phase was dried over anhydrous magnesium sulfate, the organic solvent was removed under reduced pressure, and the residue was separated by silica gel column chromatography to obtain benzene represented by formula 3-1. And furyl ester, its productive rate is 90%, and structural characterization data is as follows: 1 H NMR (600MHz, acetone) δ: 8.37(s, 1H), 8.33(s, 1H), 7.49(s, 1H), 7.35(s, 1H), 4.35(q, J=7.1Hz, 2H), 2.34 (s, 3...

Embodiment 2

[0022]

[0023] 1. Take 2.0g (16.4mmol) of salicylaldehyde shown in formula 2-2 and dissolve it in 30mL of toluene and THF in a mixed solvent with a volume ratio of 1:1, cool the system to -78°C, add 2.6mL (90 %, 24.6mmol) ethyl diazoacetate, 0.3mL (50%, 0.16mmol) tetrafluoroborate ethyl ether complex, the system was slowly warmed up to room temperature, after 12 hours of reaction, the solvent was removed under reduced pressure, and the system was added 3mL of concentrated sulfuric acid, stirred for 1 hour, extracted with ethyl acetate, the organic phase was dried over anhydrous magnesium sulfate, the organic solvent was removed under reduced pressure, and the residue was separated by silica gel column chromatography to obtain the benzene compound shown in formula 3-2. And furyl ester, its productive rate is 92%, and structural characterization data is as follows: 1 H NMR (600MHz, CDCl 3 )δ: 8.24 (s, 1H), 8.10-8.04 (m, 1H), 7.54-7.49 (m, 1H), 7.38-7.32 (m, 2H), 4.40 (q, J=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com