Space multi-factor environment comprehensive protection material and protection structure

A technology of protective materials and protective structures, which is applied in the structural field of space multi-factor environmental protection, and can solve the problems of structural material strength decline, thickness loss, and quality loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

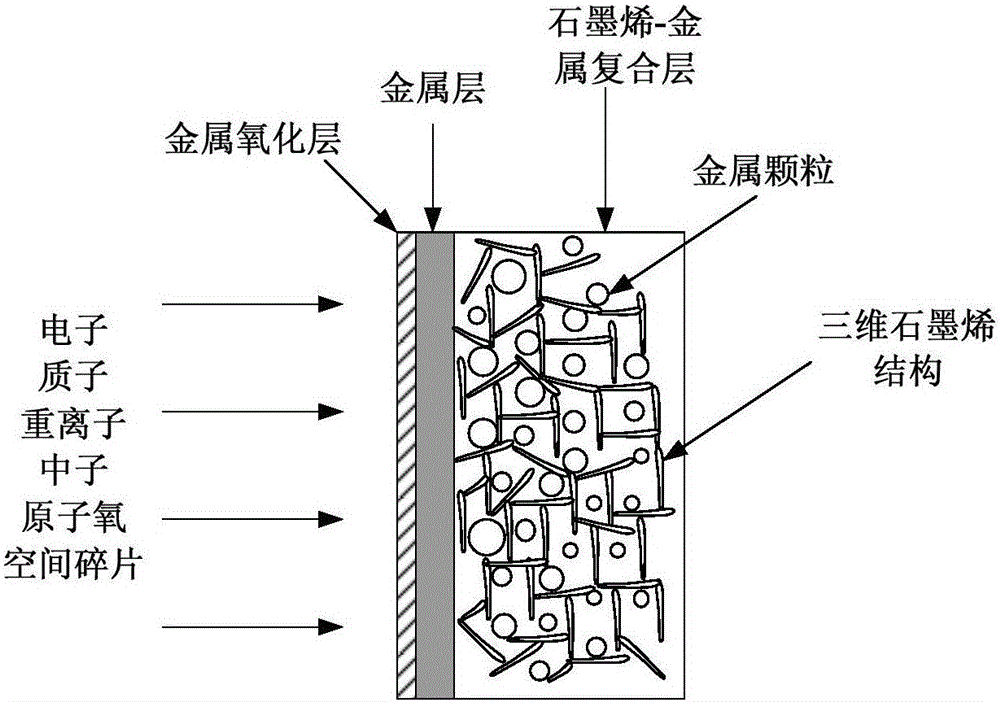

[0028] Example 1 Preparation of aluminum layer space multi-factor environment comprehensive protection material

[0029] Aluminum is heated to the temperature of its melting point (660.4° C.) to obtain an aluminum melt, and the aluminum melt is added to a commercially available three-dimensional graphene powder material, and aluminum accounts for 3% of the total weight of the aluminum melt and the three-dimensional graphene powder. %, using ultrasonic waves for individual dispersion, based on the capillary effect, the aluminum infiltrates into the three-dimensional graphene powder, cools and solidifies into a solid, and obtains a structure in which aluminum particles are tracklessly dispersed into the pores of the three-dimensional graphene.

Embodiment 2

[0030] Example 2 Preparation of comprehensive protective material for multi-factor environment in iron layer space

[0031] Heating iron to a temperature above its melting point (1535° C.) to obtain aluminum melt, adding the aluminum melt to commercially available three-dimensional graphene tube powder materials, iron accounts for the total amount of iron melt and three-dimensional graphene tube powder. 3% by weight, using ultrasonic waves to disperse, based on the capillary effect, aluminum penetrates into the three-dimensional graphene tube, cools and solidifies into a solid, and obtains a structure in which aluminum particles are tracklessly dispersed into the pores of the three-dimensional graphene tube.

Embodiment 3

[0032] Example 3 Preparation of aluminum layer space multi-factor environment comprehensive protection material

[0033] Mix the aluminum powder with the commercially available three-dimensional graphene powder material, the aluminum powder accounts for 5% of the total weight of the aluminum powder and the three-dimensional graphene powder, place it in a special high-temperature resistant container, and heat it to the temperature of the aluminum Above the melting point temperature, and then cooled and solidified into a solid, a structure in which aluminum particles are tracklessly dispersed into the pores of three-dimensional graphene is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com