Softening agent for rayon embroidery thread

A softener and embroidery thread technology, applied in the field of fabric softener, can solve the problems of low oiling rate and uneven oiling, and achieve the effects of reducing friction, reducing static electricity and good antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A softener for rayon embroidery threads according to the invention, the components and mass percentages are as follows: 20% of quaternary ammonium-based cationic modified aminosiloxane, 5% of ester-based quaternary ammonium salt, nonionic emulsifier secondary alcohol polyoxyethylene Ether (15-S-5:15-S-9=3:7) was 10%, acetic acid was 0.2%, and deionized water was 64.8%. In a variable speed mixer, first add quaternary ammonium cationic modified aminosiloxane and nonionic emulsifier secondary alcohol polyoxyethylene ether and stir evenly, then add ester quaternary ammonium salt and stir, and finally add acetic acid and remove Ionized water, emulsification reaction; stir evenly and distribute.

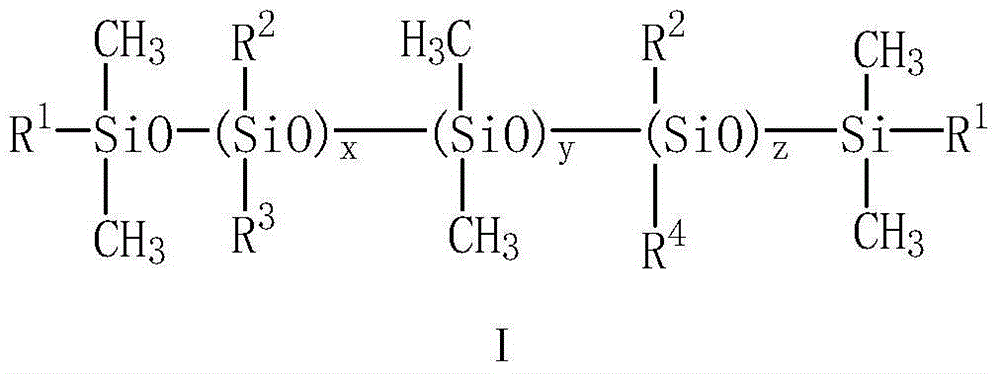

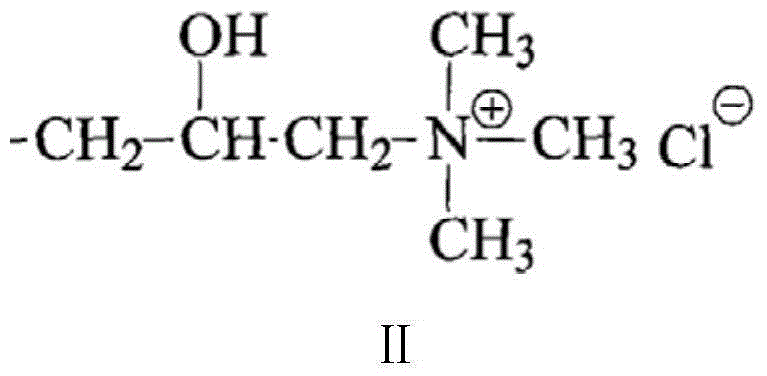

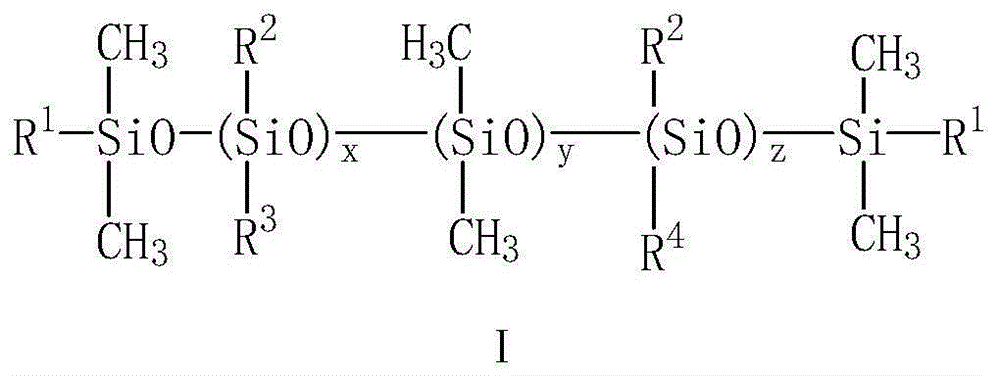

[0021] Among them, the quaternary ammonium cationic modified aminosiloxane is such as the general formula I, where R 1 is an alkoxy group; R 2 is methyl; R 3 for-C 3 h 6 OCH 2 CH(OH)CH 2 N(CH 3 ) 2 ; 4 For formula II; x=150, y=100, z=90.

[0022]

Embodiment 2

[0024] A softener for rayon embroidery threads according to the invention, the components and mass percentages are as follows: 10% of quaternary ammonium-based cationic modified aminosiloxane, 1% of ester-based quaternary ammonium salt, nonionic emulsifier secondary alcohol polyoxyethylene Ether (15-S-5:15-S-12=1:1) was 5%, citric acid was 0.1% and deionized water was 83.9%. In the variable speed mixer, first add quaternary ammonium cationic modified aminosiloxane and nonionic emulsifier secondary alcohol polyoxyethylene ether and stir evenly, then add ester quaternary ammonium salt and stir, and finally add citric acid and Deionized water, emulsification reaction; stir evenly and distribute.

[0025] Among them, the quaternary ammonium cationic modified aminosiloxane is such as the general formula I, where R 1 is hydroxyl; R 2 is hydroxyl; R 3 for-C 3 h 6 OCH 2 CH(OH)CH 2 N(CH 2 CH 3 ) 2 ; 4 For formula II; x=105, y=100, z=10.

Embodiment 3

[0027] A softener for rayon embroidery thread according to the invention, the components and mass percentages are as follows: 30% of quaternary ammonium-based cationic modified aminosiloxane, 8% of ester-based quaternary ammonium salt, nonionic emulsifier secondary alcohol polyoxyethylene Ether (15-S-5:15-S-12=2:1) was 15%, glycolic acid was 0.5% and deionized water was 46.5%. In a variable speed mixer, first add quaternary ammonium cationic modified aminosiloxane and nonionic emulsifier secondary alcohol polyoxyethylene ether and stir evenly, then add ester quaternary ammonium salt and stir, and finally slowly add glycolic acid and Deionized water, emulsification reaction; stir evenly and distribute.

[0028] Among them, the quaternary ammonium cationic modified aminosiloxane is such as the general formula I, where R 1 is hydroxyl; R 2 is hydroxyl; R 3 for-C 3 h 6 OCH 2 CH(OH)CH 2 R 4 For formula II; x=360, y=300, z=180.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com