An injection-molded flushing channel for an all-plastic toilet

An injection molding, toilet technology, applied in flushing toilets, water supply devices, urinals, etc., can solve problems such as low work efficiency, achieve high flushing efficiency, suitable shape, and overcome the effects of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

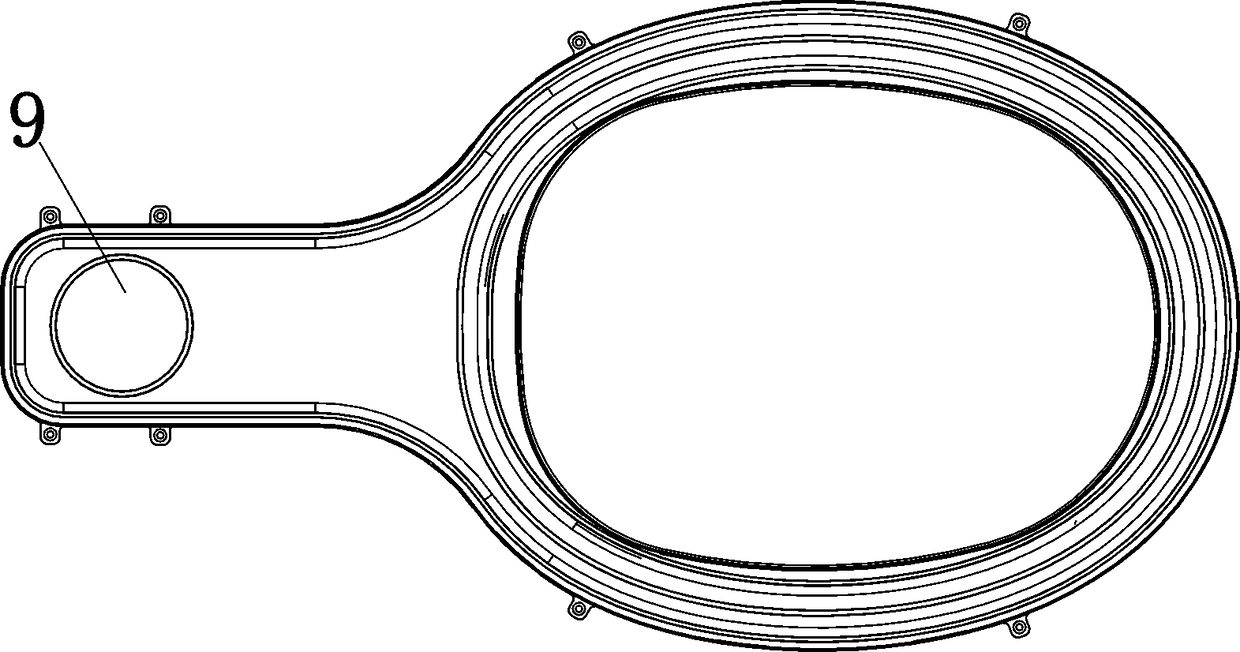

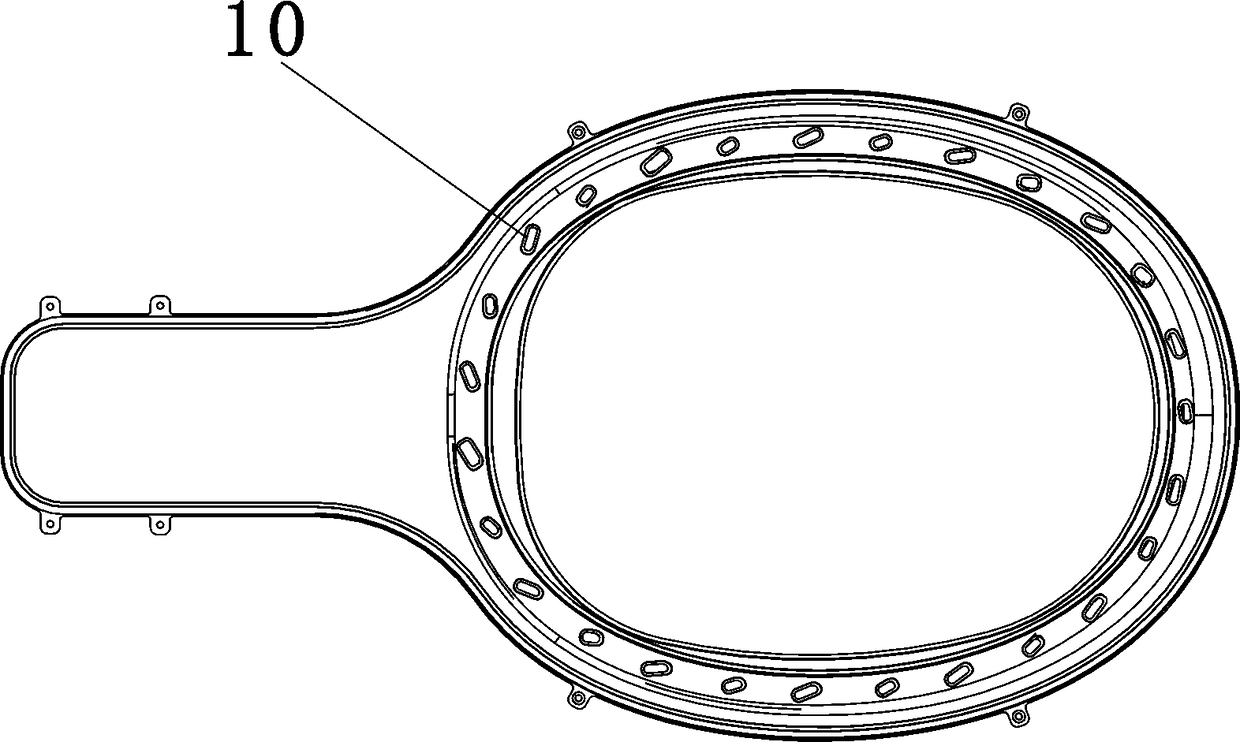

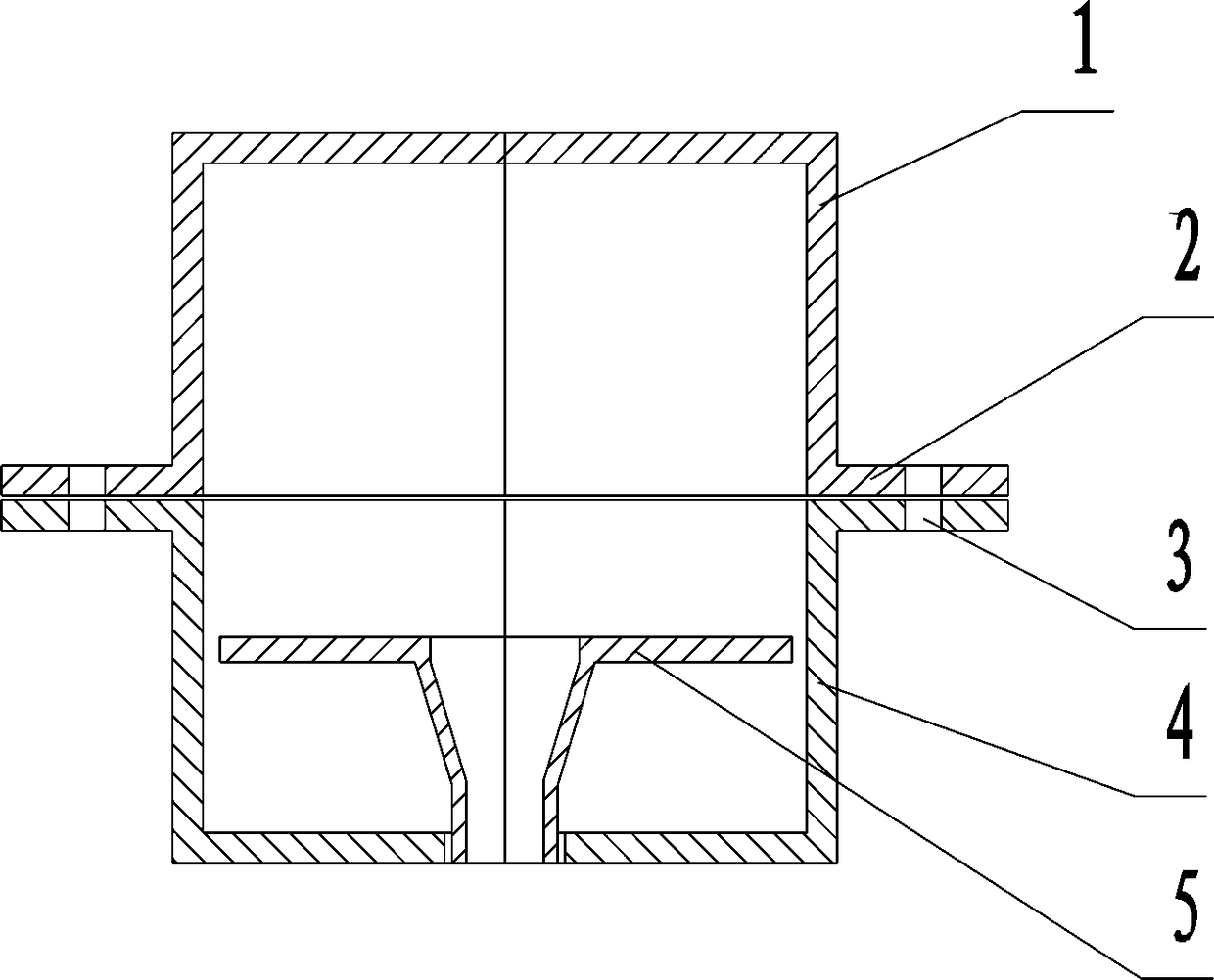

[0037] Embodiment 1: the first step, form the upper shell, the lower shell, and the flushing nozzle plate installed in the lower shell respectively with the injection molding process, see figure 1 , figure 2 , image 3 . The materials used are all polypropylene. In the second step, after the above three parts are matched and aligned, they are placed in the injection mold cavity of the horizontal U-shaped inner and outer rings, and injection molded again to form the inner and outer rings connecting the upper shell and the lower shell Horizontal U-shaped enclosure. The flanges of the upper and lower shells are embedded in the U-shaped grooves, and the surrounding bars have plastic rivets with a diameter of about 1.5mm that penetrate up and down in the vertical direction every 30-50mm. See Figure 4 . The fence material is ABS. After the two-step process, the flushing channel components are completed without post-processing.

Embodiment 2

[0038] Embodiment 2: With reference to Embodiment 1, the difference is that the lower shell and the flushing nozzle plate installed in the lower shell are formed into an integral part at one time, that is, the first step is to mold the upper shell respectively with the injection molding process. The lower housing of the flushing nozzle. In the second step, after the above-mentioned two parts are matched and aligned, the inner and outer ring horizontal U-shaped enclosures for connection are formed by injection molding. Compared with Embodiment 1, the mold structure of the lower housing with the flushing nozzle is more complicated, but the workload of separately forming the flushing nozzle plate can be reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com