Floating type deep sea automatic mining robot

A robotic and automatic technology, applied in the mining of minerals, special mining, earth-moving drilling, etc., can solve problems such as inability to effectively collect minerals, inconvenient walking, and inability to effectively locate areas with complex terrain, and achieve efficient and environmentally friendly collection. , stable operation, little disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

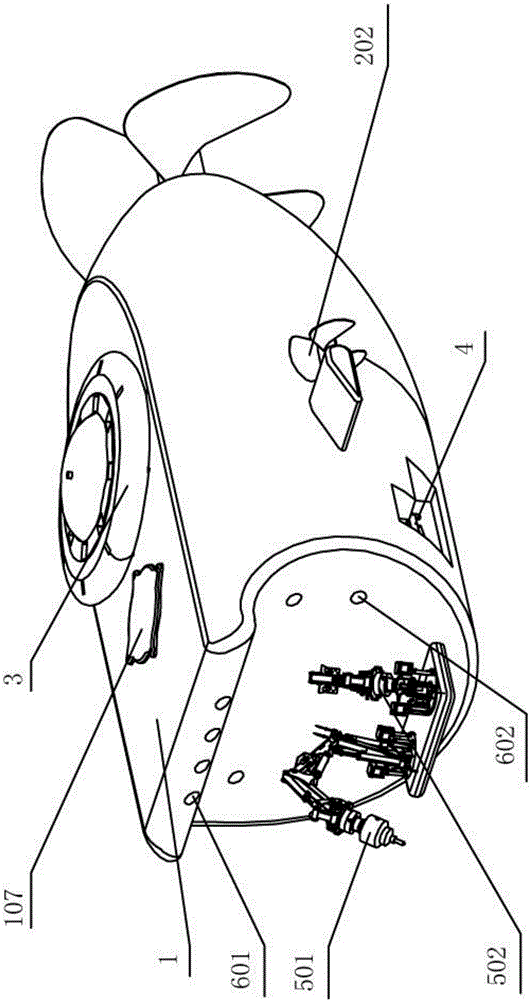

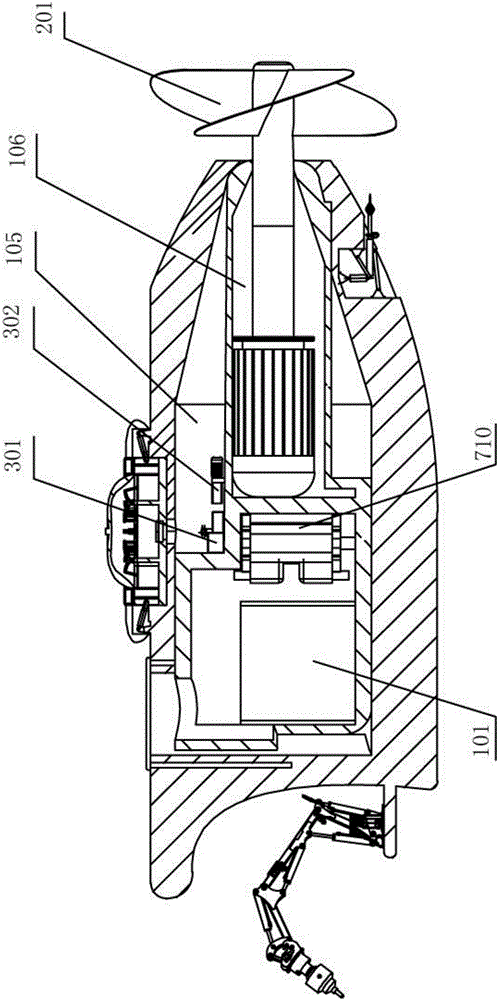

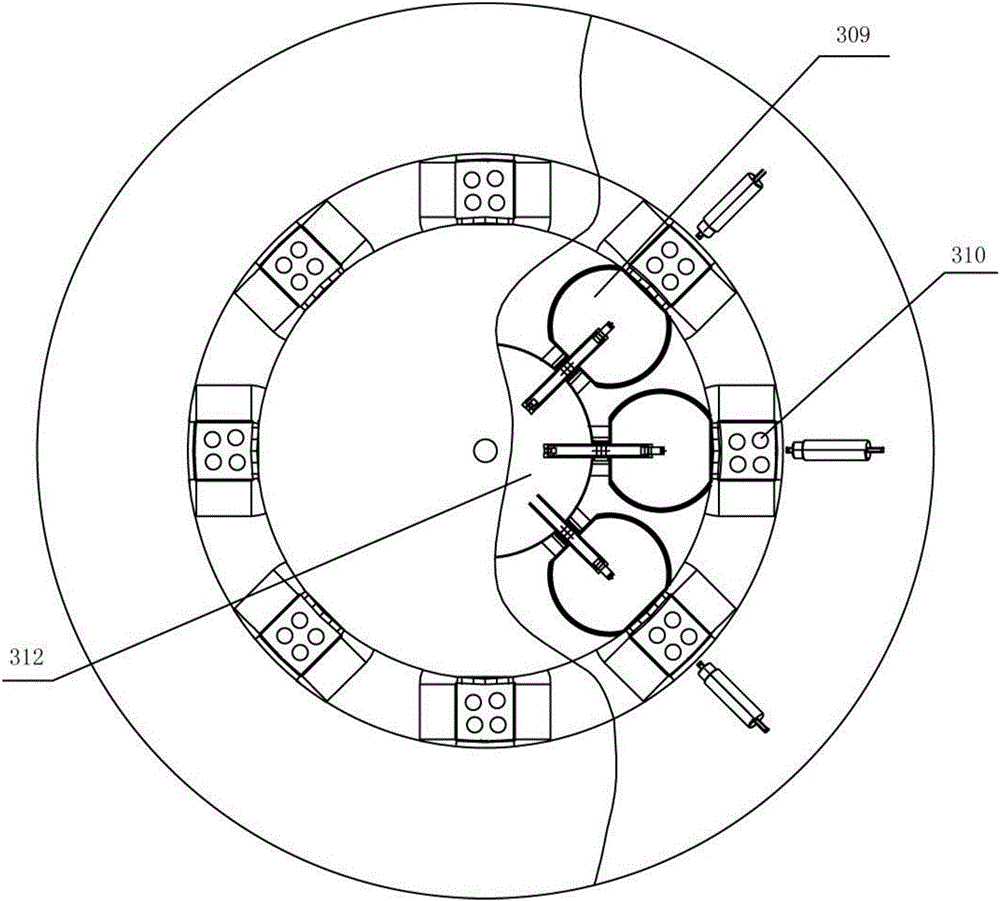

[0031] A floating type deep-sea automatic mining robot, such as Figure 1-Figure 6 As shown, it includes the fuselage 1, the propulsion system, the hydraulic control inlet and drainage system 3, the mining system, the lighting detection system and the hydraulic control system, the propulsion system, the hydraulic control inlet and drainage system 3, the mining system, the lighting detection system and the hydraulic The control systems are all installed on the fuselage 1. The propulsion system includes a main propeller 201 and two side propellers 202. The two side propellers 202 are installed on the left and right sides of the fuselage 1. The main propeller 201 is installed at the rear of the fuselage 1, and the mining system includes a three-jaw multi-degree-of-freedom manipulator 501 and a vibration crushing device 502. The three-jaw multi-degree-of-freedom manipulator 501 and the vibration crushing device 502 are installed side by side at the front of the fuselage 1. The syst...

Embodiment 2

[0033] A floating type deep-sea automatic mining robot, such as Figure 1-Figure 6 As shown, it includes the fuselage 1, the propulsion system, the hydraulic control inlet and drainage system 3, the mining system, the lighting detection system and the hydraulic control system, the propulsion system, the hydraulic control inlet and drainage system 3, the mining system, the lighting detection system and the hydraulic The control systems are all installed on the fuselage 1. The propulsion system includes a main propeller 201 and two side propellers 202. The two side propellers 202 are installed on the left and right sides of the fuselage 1. The main propeller 201 is installed at the rear of the fuselage 1, and the mining system includes a three-jaw multi-degree-of-freedom manipulator 501 and a vibration crushing device 502. The three-jaw multi-degree-of-freedom manipulator 501 and the vibration crushing device 502 are installed side by side at the front of the fuselage 1. The syst...

Embodiment 3

[0036] A floating type deep-sea automatic mining robot, such as Figure 1-Figure 6 As shown, it includes the fuselage 1, the propulsion system, the hydraulic control inlet and drainage system 3, the mining system, the lighting detection system and the hydraulic control system, the propulsion system, the hydraulic control inlet and drainage system 3, the mining system, the lighting detection system and the hydraulic The control systems are all installed on the fuselage 1. The propulsion system includes a main propeller 201 and two side propellers 202. The two side propellers 202 are installed on the left and right sides of the fuselage 1. The main propeller 201 is installed at the rear of the fuselage 1, and the mining system includes a three-jaw multi-degree-of-freedom manipulator 501 and a vibration crushing device 502. The three-jaw multi-degree-of-freedom manipulator 501 and the vibration crushing device 502 are installed side by side at the front of the fuselage 1. The syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com