Method and system for realizing p-type nitride enhanced hemt through in-situ etch monitoring

An in-situ etching and nitride technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., to achieve the effect of avoiding over-etching, avoiding incomplete etching, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be explained in more detail below. However, it should be understood that within the scope of the present invention, the above-mentioned technical features of the present invention and the technical features specifically described in the following (eg, the embodiments) can be combined with each other to form new or preferred technical solutions. Due to space limitations, it is not repeated here.

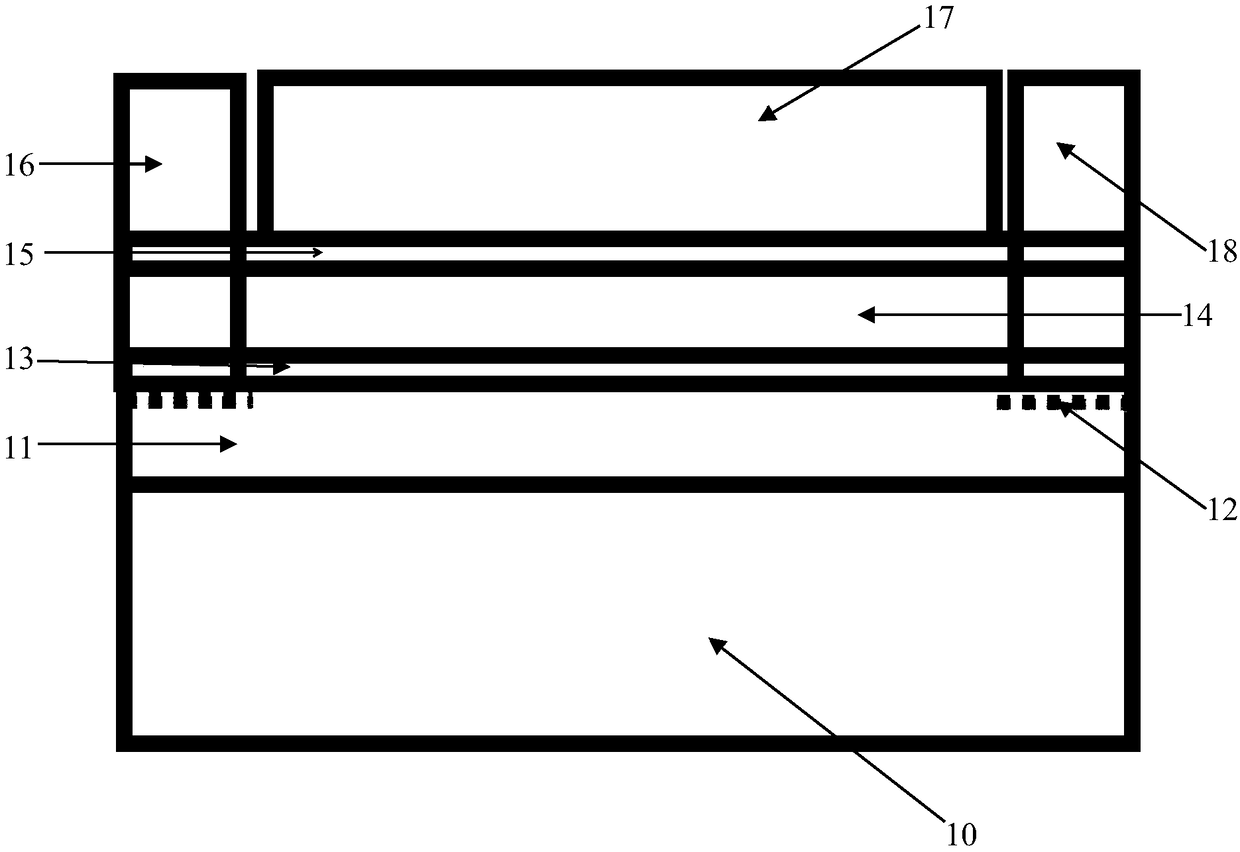

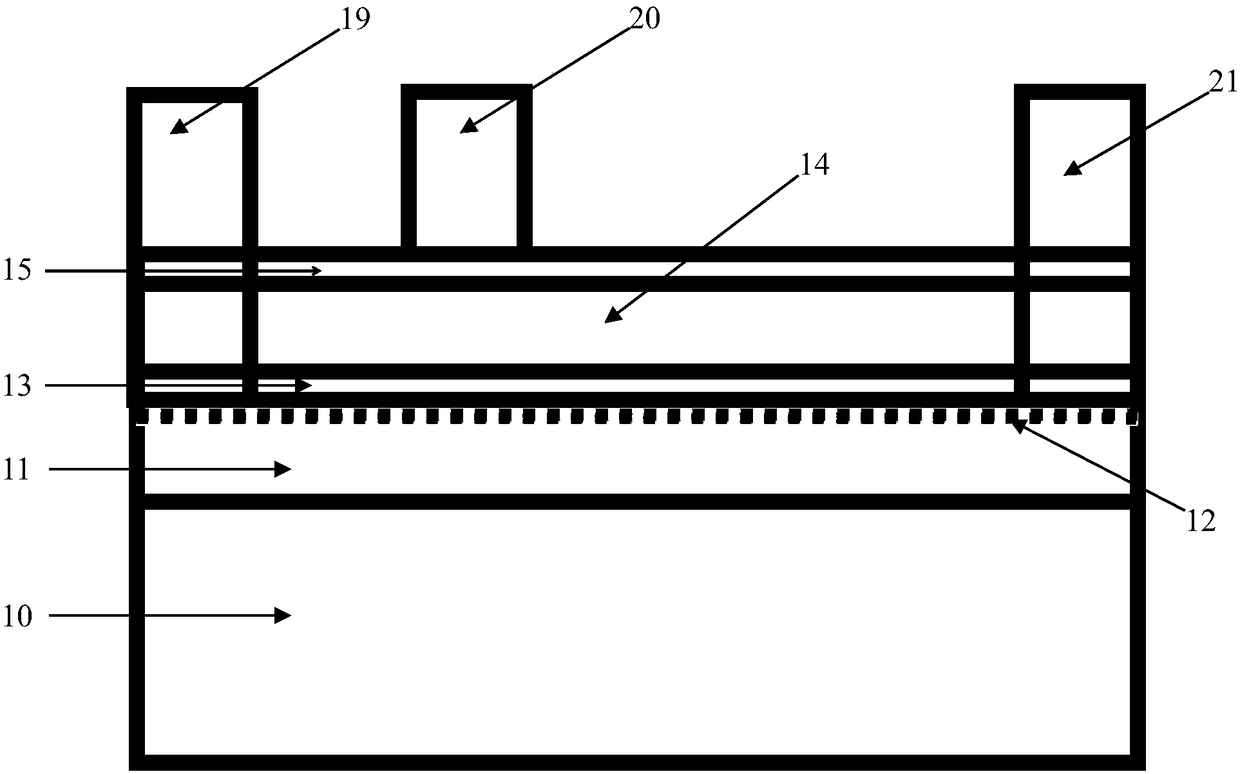

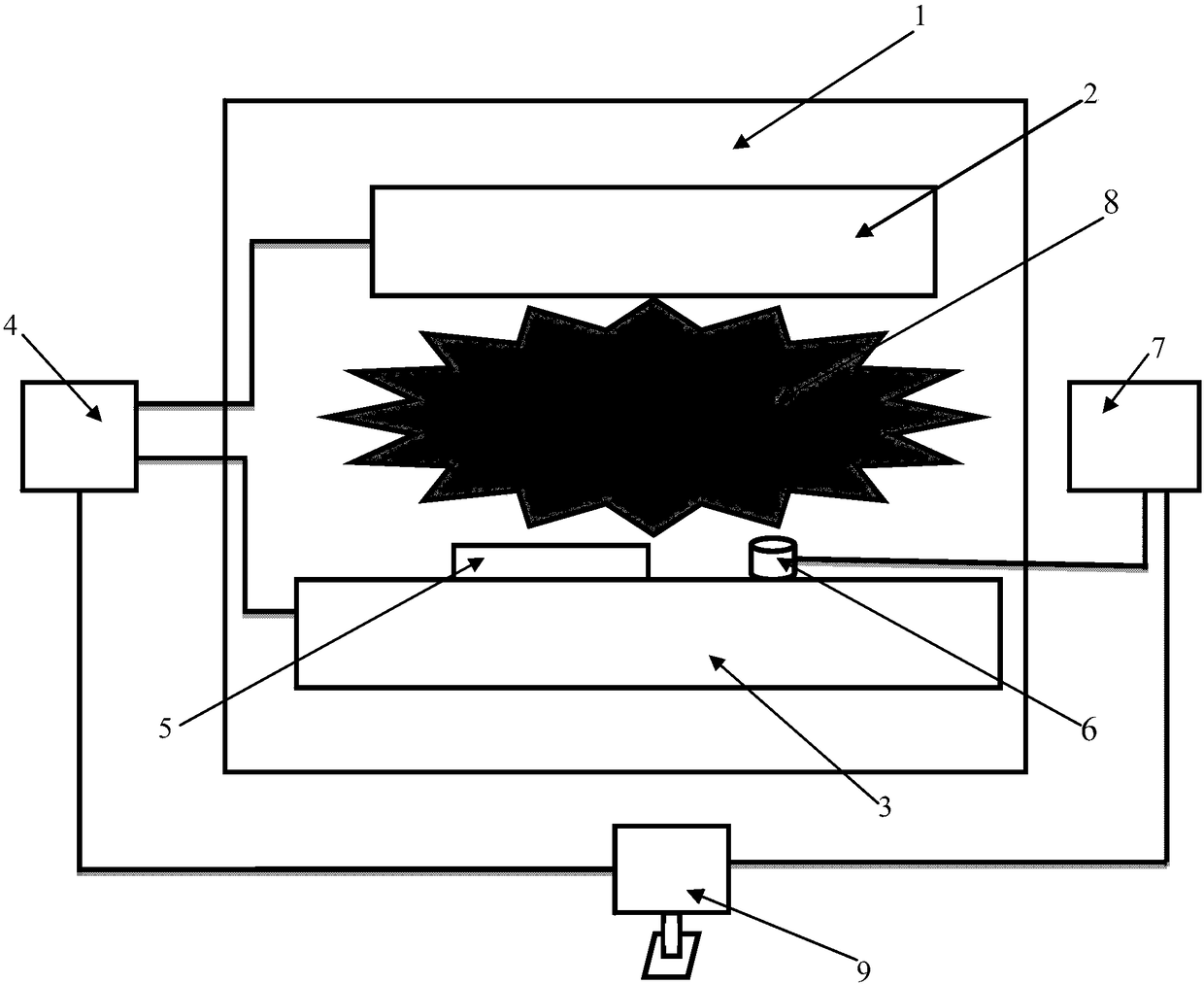

[0026] An embodiment of the present invention provides a method for realizing a P-type nitride-enhanced HEMT by monitoring in-situ etching, which includes:

[0027] Place the etched sample and the counterplate at the equivalent etching position in the etching equipment to ensure that the etched sample and the counterplate are under the same etching conditions, and the counterplate has the same epitaxy as the etched sample structure, and the co-plate has two electrodes, and the two electrodes are electrically connected by tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com