Machining and manufacturing method for anti-deformation three-layer plate

A production method and three-layer board technology are applied in the direction of wood processing appliances, wood veneer bonding, manufacturing tools, etc., which can solve the problem of low resistance to temperature and humidity deformation, save the shaping process, improve the moisture content, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

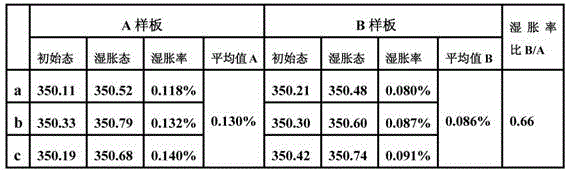

Image

Examples

Embodiment Construction

[0022] The processing and manufacturing method of the anti-deformation three-layer board of the present invention comprises the following steps:

[0023] 1. Select solid wood veneers that are peeled with poplar or eucalyptus, and use three veneers of the same wood species with a moisture content of 20-40% as the upper, middle and middle layers of the three-layer board. The lower plate; the three rotary-cut veneers have the same format size and the same thickness.

[0024] 2. Apply glue on the glued surface of the upper layer, middle layer and lower layer with a gluing machine and then assemble the blanks. The way of forming the blanks is that the grain direction of the upper layer and the lower layer are the same, and the grain direction of the middle layer is the same as that of the upper layer and the lower layer. The grain direction is perpendicular to.

[0025] 3. Properly repair the three-ply board after pre-pressing. The method of pre-pressing and repairing is the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com