Energy-saving heat pump type intermediate-temperature spray evaporation system

A technology of spray evaporation and spray system, which is used in general water supply conservation, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of increased heat dissipation, manual cleaning, inconvenient operation, etc., and achieve compact equipment. , high flexibility, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

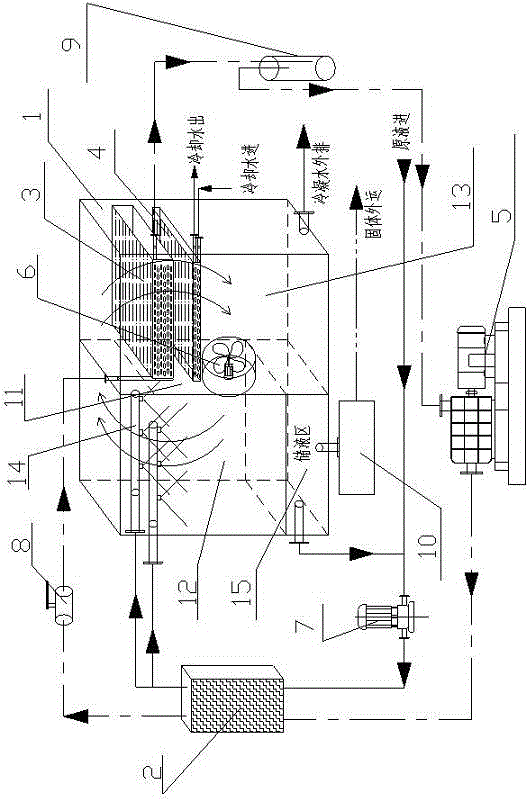

[0021] like figure 1 As shown, an energy-saving heat pump medium-temperature spray evaporation system of the present technology includes an evaporation separation chamber 1, a condenser (refrigerant) 2, an evaporator (refrigerant) 3, a water cooler 4, a heat pump 5, an axial blower 6, and a circulating water pump 7 , Throttling device 8, gas-liquid separator / purifier 9, solid-liquid separator 10, partition 11, evaporation chamber 12, separation chamber 13, spray system 14, liquid storage area 15.

[0022] The evaporation and separation chamber 1 is divided into an evaporation chamber 12 and a separation chamber 13 by a partition 11. An axial blower 6 is installed in the middle of the partition 11 and a cold air inlet is left, and a hot air outlet is formed between the top of the partition and the inner wall of the evaporation and separation chamber; the evaporation chamber 12 The bottom is a liquid storage area 15, and the top is equipped with a spray system 14; the liquid sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com