Preparing method of flame-retardant, anti-bacterial and waterproof graphene modified acrylate resin paint

A technology of graphene modification and resin coating, which is applied in the direction of antifouling/underwater coating, fireproof coating, coating, etc. It can solve the problems of production equipment, production process and production scale gap, etc., and achieve light color and high extraction efficiency , less toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

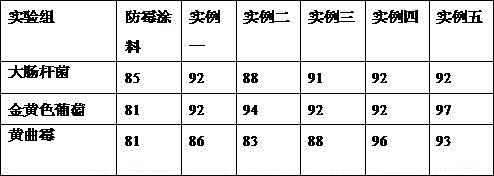

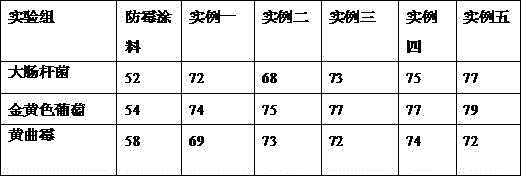

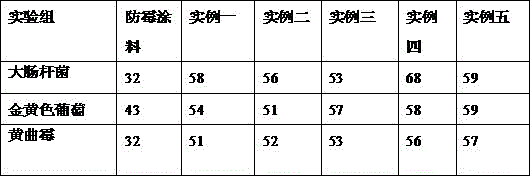

Examples

example 1

[0024] (1) walnut green husk extract concentrate, it is characterized in that the method comprises the steps of: peel off the walnut green husk, wash with water, place in an oven and dry to constant weight at a temperature of 40°C, pulverize and pass through an 80-mesh sieve to obtain Walnut green husk powder, weigh 50g of walnut green husk powder and 150g of water, add 2.5g of allyltrimethylammonium chloride, 1g of methyl 4-methoxyacetoacetate, decoct under reflux at 80°C, filter the decoction , concentrating under reduced pressure at 60°C, until the concentrated solution becomes a thick paste with a water content of 15% to 20% to a constant weight, to obtain a concentrated walnut green husk extract;

[0025] (2) Add 60 mg of graphene to 50 mL of N-methylpyrrolidone, 20 g of tetrabutylammonium hydroxide, and 0.2 g of tetrabutylammonium hydroxide, ultrasonically disperse for 30 minutes, and centrifuge at a speed of 2000 rpm to obtain a graphene dispersion;

[0026] (3) Add 80g...

example 2

[0030] (1) walnut green husk extract concentrate, it is characterized in that the method comprises the steps of: peeling walnut green husk and washing with water, placing in an oven at a temperature of 70°C and drying to constant weight, pulverizing and passing through a 100-mesh sieve to obtain Walnut green husk powder, weigh 60g of walnut green husk powder and 180g of water, add 3g of allyltrimethylammonium chloride, 1.2g of methyl 4-methoxyacetoacetate, reflux and decoct at 100°C, filter the decoction Concentrate under reduced pressure at a temperature of 70°C, wait until the concentrated solution becomes a thick paste with a water content of 15% to 20% to a constant weight, and obtain a concentrated solution of walnut green husk extract;

[0031] (2) Add 60 mg of graphene to 50 mL of N-methylpyrrolidone, 20 g of tetrabutylammonium hydroxide, and 0.2 g of tetrabutylammonium hydroxide, ultrasonically peel for 30 minutes, and centrifuge at a speed of 2000 rpm to obtain a graph...

example 3

[0036] (1) walnut green husk extract concentrate, it is characterized in that the method comprises the steps of: washing walnut green husk with water after peeling off, placing in an oven at a temperature of 55° C. to dry to constant weight, pulverizing and passing through a 90-mesh sieve to obtain Walnut green husk powder, weigh 50g of walnut green husk powder and 150g of water, add 2.5g of allyltrimethylammonium chloride, 1g of methyl 4-methoxyacetoacetate, decoct under reflux at 90°C, filter the decoction Concentrate under reduced pressure at a temperature of 65°C, and wait until the concentrated solution becomes a thick paste with a water content of 15% to 20% to a constant weight to obtain a concentrated solution of walnut green husk extract;

[0037] (2) Add 60mg of graphene to 50mL of N-methylpyrrolidone, 20g of tetrabutylammonium hydroxide, and 0.2g of tetrabutylammonium hydroxide, and ultrasonically disperse

[0038] 30min, centrifuged at a speed of 2000rpm to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com