Closed inner circulation type tobacco drying device

A drying device and internal circulation technology, which is applied in the direction of tobacco drying, drying, tobacco, etc., can solve the problems of single drying mode, time-consuming and labor-intensive, and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

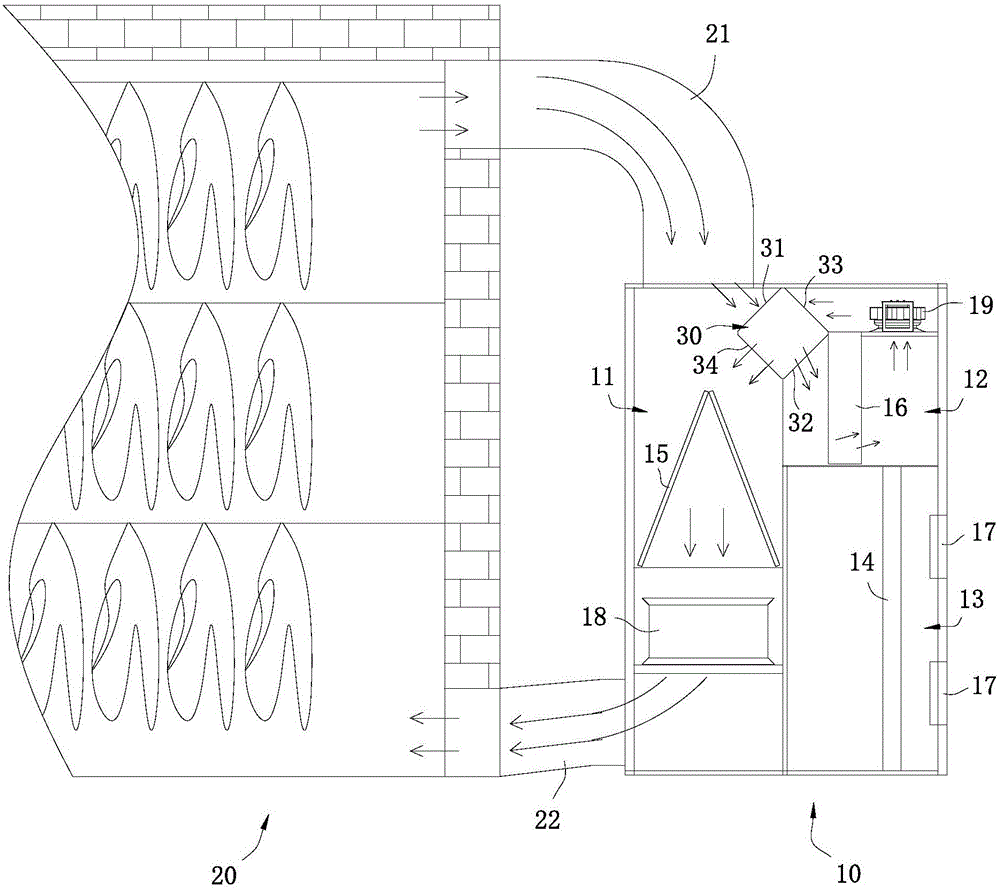

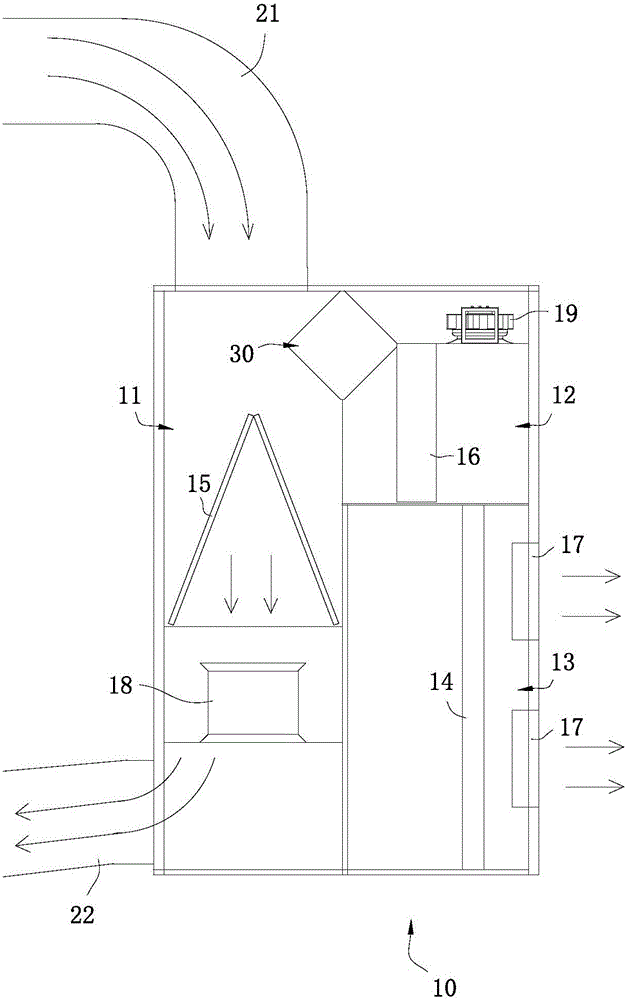

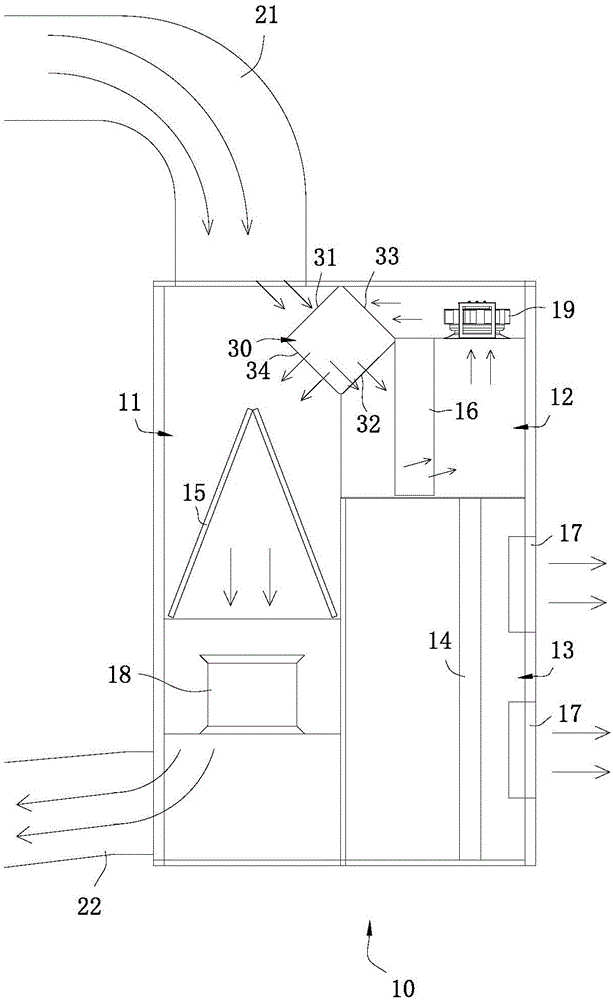

[0019] refer to Figure 1 to Figure 7 , a closed internal circulation tobacco drying device of the present invention, comprising a drying chamber 20 and a drying body 10, the top and bottom of the drying body 10 are respectively provided with an air inlet duct 21 and a The air outlet duct 22 and the inside of the dryer body 10 form a sealed chamber, which is separated by a sensible heat exchanger 30 to form a first chamber 11 and a second chamber 12 connected to each other. The dryer body 10 also has The accommodation chamber 13 that communicates with the outside world is provided with a first heat exchanger 14 in the accommodation chamber 13, and the top and bottom of the first chamber 11 communicate with the air inlet air duct 21 and the air outlet air duct 22 respectively. A second heat exchanger 15 is provided in the middle of a chamber 11, a third heat exchanger 16 is provided in the second chamber 12, and a control first heat exchanger 14 and a second heat exchanger 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com