Production method of high-temperature-resistant low-shrinkage PVC cable material

A production method and cable material technology, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, electrical components, etc., can solve problems such as unsuitable production and processing, increased energy consumption of raw material melting, residual moisture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

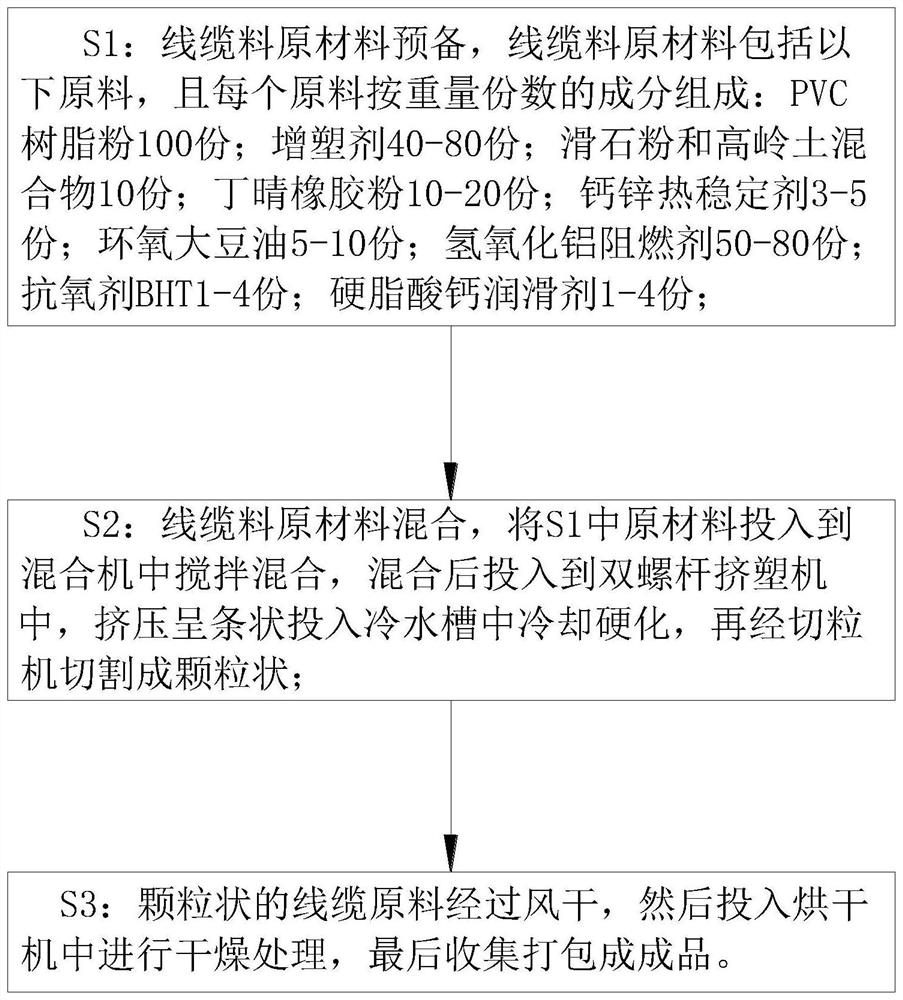

Method used

Image

Examples

Embodiment approach

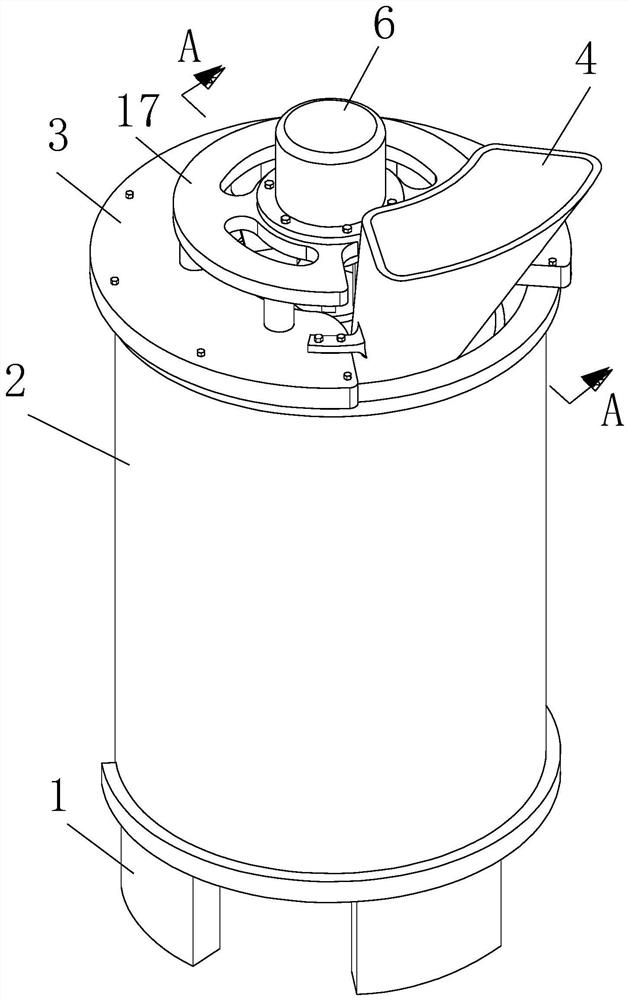

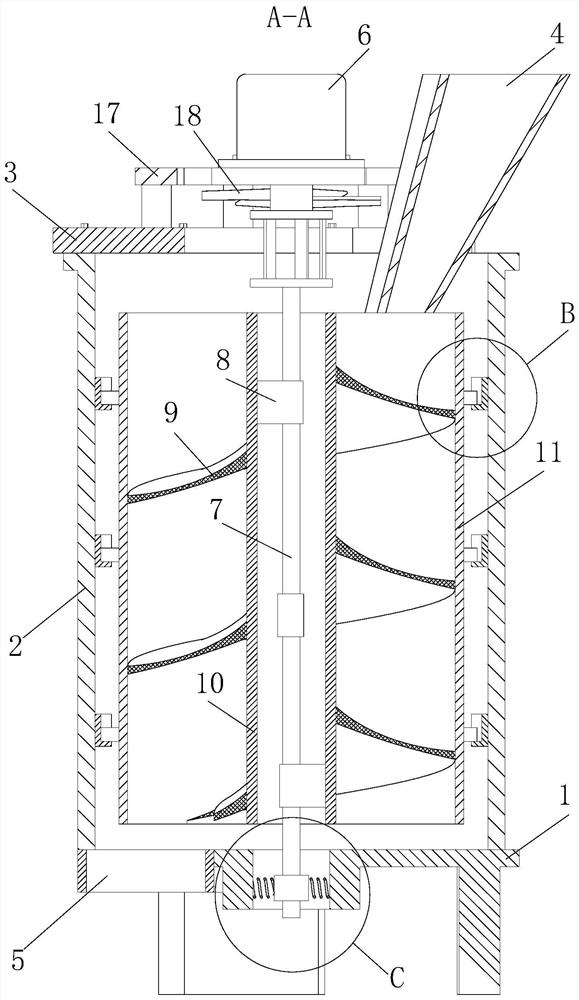

[0034]As an embodiment of the present invention, the soft start mechanism includes the first disc 14, the second disc 15 and the rubber belt 16; the middle position of the first disc 14 is fixedly connected to the output shaft of the motor 6, and the first disc 14 is One end of a plurality of rubber belts 16 is evenly fixed to the outer ring of the board surface, and the other end of the rubber belt 16 is fixed to the outer ring of the second disc 15, and the middle position of the second disc 15 is fixed to the upper end of the rotating shaft 7; Fixed multiple cams 8 rotate to generate vibration, and the rotating shaft 7 and the sleeve 10 will oscillate in the horizontal direction. If the rotating shaft 7 is directly fixed on the output shaft of the motor 6, the vibration will cause damage to the motor 6, and the rotating shaft 7 will pass through the soft The starting mechanism is connected to the output shaft of the motor 6, and since the rubber belt 16 can buffer the swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com