Flame retardant coating agent for vehicle seat, and manufacturing method for flame-retardant vehicle seat material

A vehicle seat, flame retardant technology, applied in the field of flame retardant coating agents, can solve problems such as increased blank weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

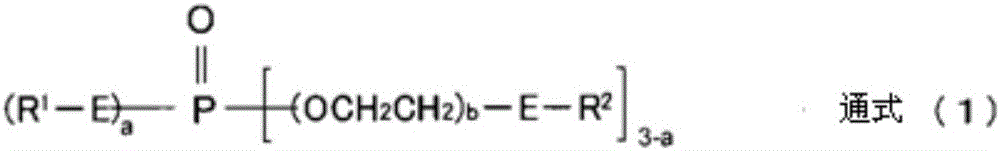

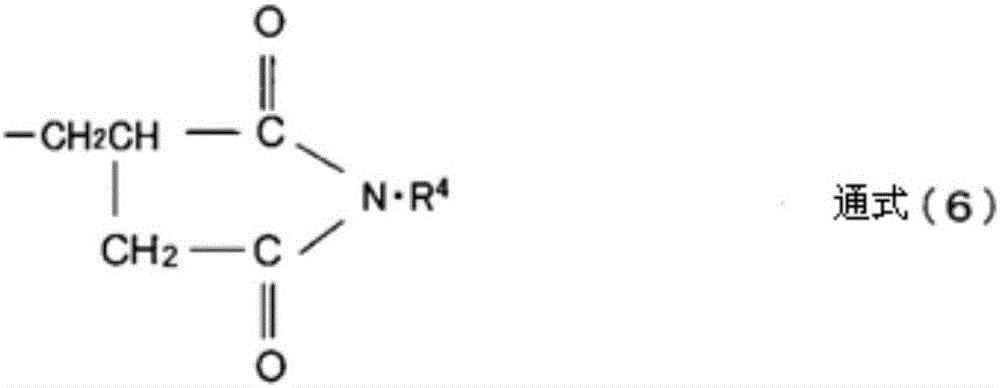

Method used

Image

Examples

manufacture example 1

[0286] 45 parts by mass of resorcinol di-2,6-xylyl phosphate, 5 parts by mass of ethylene oxide 20 mole adduct of tristyrenated phenol (hereinafter referred to as TSP20E) and 50 parts by mass of water It was treated with a bead mill to obtain an emulsified dispersion of compound (B) (average particle diameter: 0.5 μm). Here, the bead mill treatment used Willy A. Bachofen DYNO-MILLMULTILAB type (mechanical seal method).

manufacture example 2

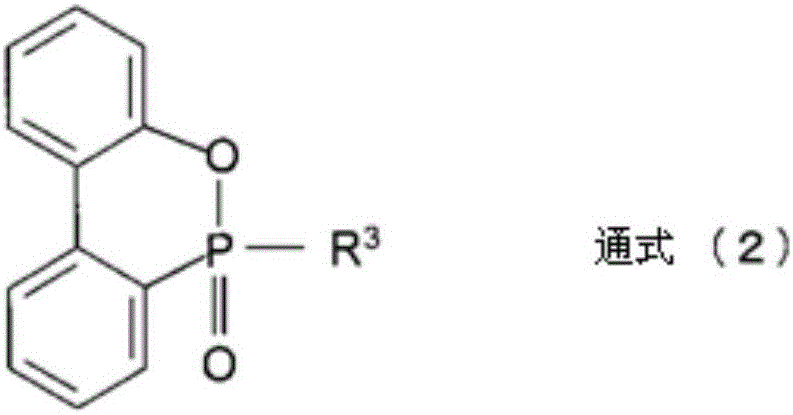

[0288] 45 parts by mass of 10-benzyl-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, sodium hydroxide neutralization product of chlorosulfonic acid reactant of TSP20E (hereinafter referred to as 3 parts by mass of TSP20ES) and 52 parts by mass of water were treated with a bead mill to obtain an emulsified dispersion of compound (B) (average particle diameter: 0.5 μm).

manufacture example 3

[0290] Resorcinol di-2,6-xylyl phosphate was used instead of biphenyl diphenyl phosphate, and dispersion treatment was carried out instead of bead mill treatment. In addition, it was operated in the same manner as in Production Example 1 to obtain An emulsified dispersion of compound (B) (average particle diameter: 0.3 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com