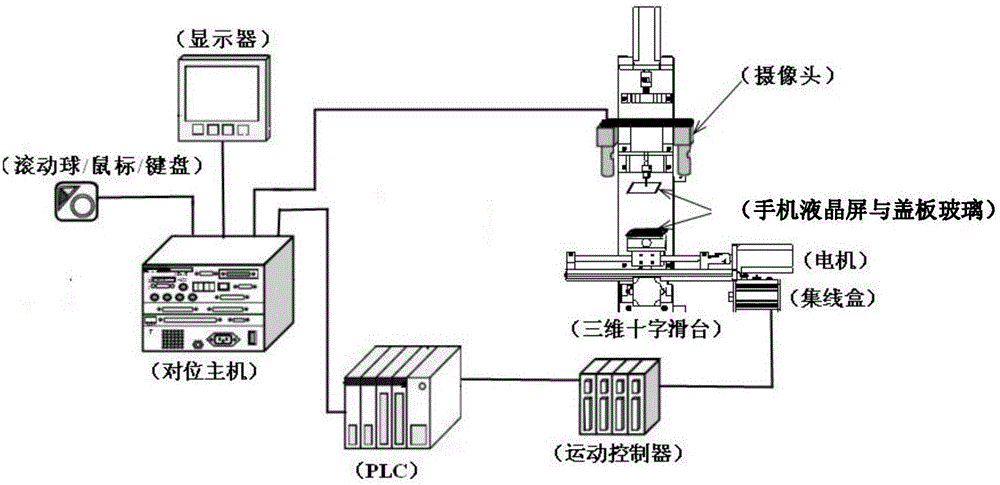

Method for attaching mobile phone cover lens to liquid crystal display

A technology for cover glass and liquid crystal screen, applied in chemical instruments and methods, lamination devices, controlled lamination, etc., can solve the problems of inconvenient use, reliance on molds, high cost, and achieve improved production efficiency, reduced labor costs, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

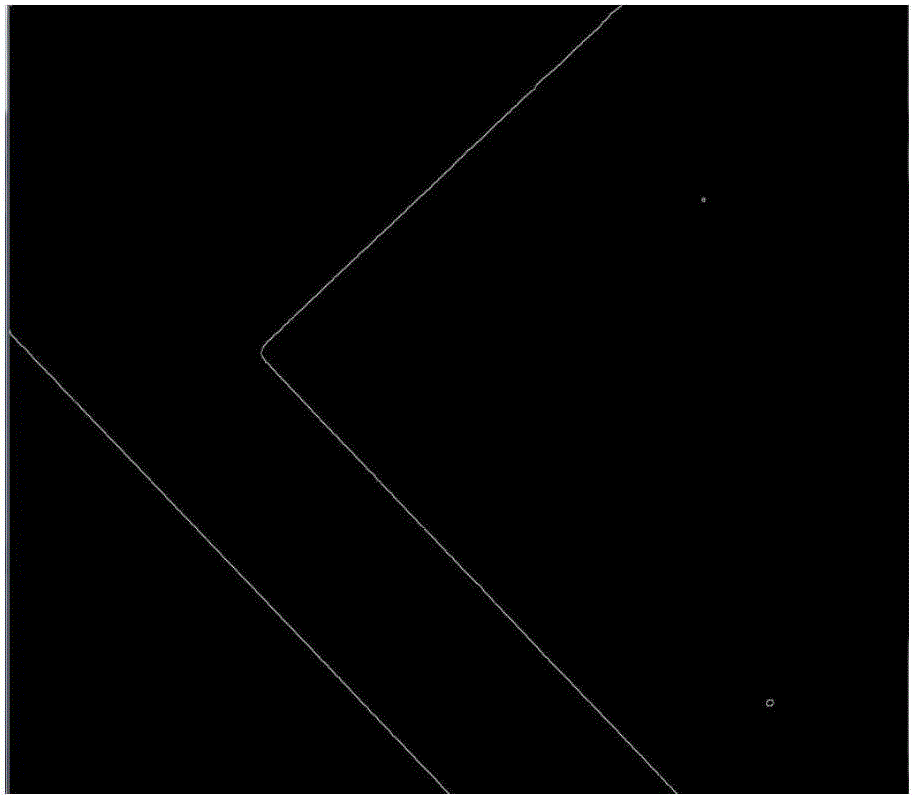

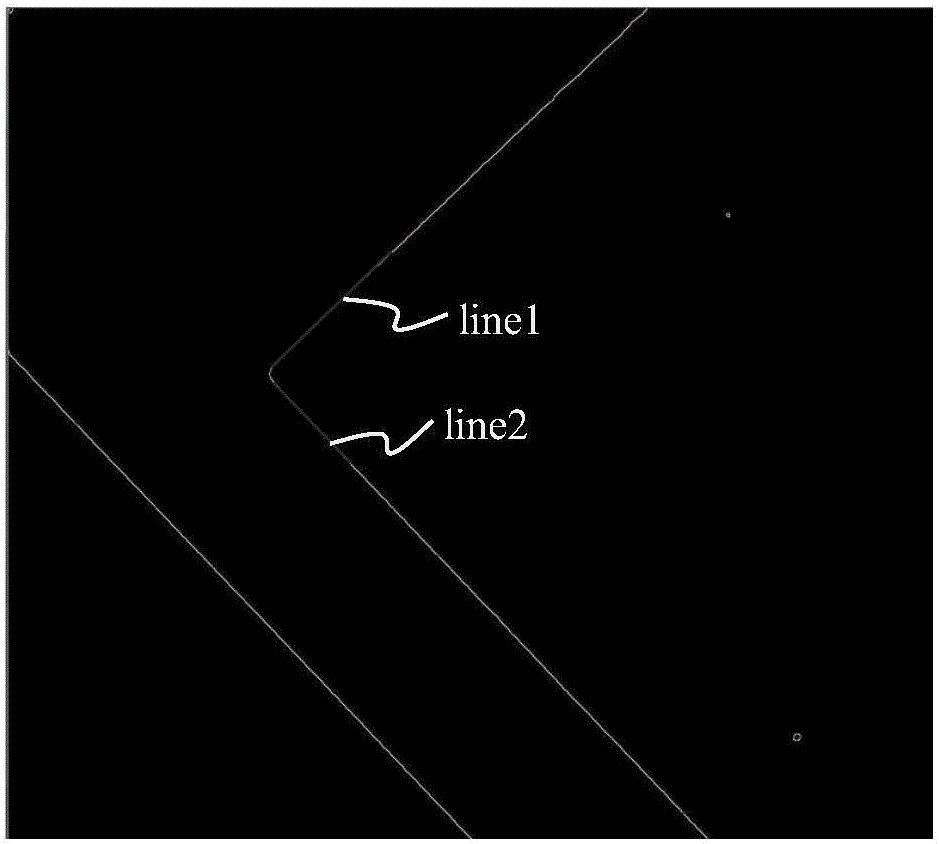

[0031] Before describing the present invention in detail, the principle of stereoscopic parallax will be briefly described. The principle of stereo parallax refers to the direction difference caused by observing the location of the target at the same position from two points separated by a certain distance. The angle between two points observed from the target is called the parallax angle of the two points, and the distance between the two points is called the baseline. When the parallax angle and baseline length are obtained, the distance between the target and the observer can be calculated. To give an example, for example, when you put a finger in front of your eyes, first close your right eye and look at it with your left eye; then close your left eye and look at it with your right eye, you will find that the position of your finger relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com