Underwater static crushing agent and preparation method thereof

A technology of static breaking agent and water reducing agent, which is applied in the field of underwater static breaking agent and its preparation, which can solve the problems of concrete engineering that cannot be statically broken directly in water, and achieve the effect of novel material selection, high safety factor, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] In this embodiment, the process of preparing the underwater static breaking agent according to the weight ratio is: 8.3Kg perburned calcium oxide, 1.25Kg ordinary Portland cement, 0.15Kg calcium chloride, 0.27Kg UWB-II flocculant and 0.03Kg Mix the polycarboxylate superplasticizer, mix and disperse evenly to make an underwater static breaker; weigh 3Kg of water with an open container, pour the above underwater static breaker into the water container, and stir while pouring until it becomes Uniform paste slurry; pour the paste slurry into the injection container, the front end of the injection container is equipped with a 2cm thick plastic tube, the length of the plastic tube is greater than the depth of the blast hole, and then the diver will pour the paste slurry in the injection container underwater Inject into the blast hole, and press the blast hole with bricks after filling; the prepared underwater static breaking agent can statically blast the underwater concrete b...

Embodiment 2

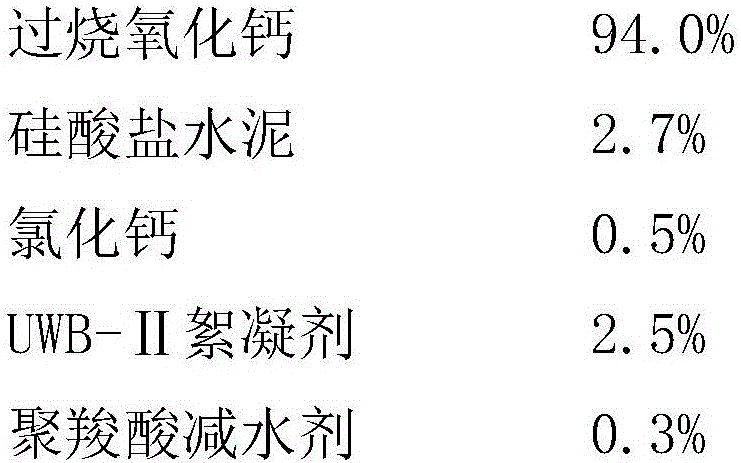

[0014] In the present embodiment, the underwater static breaking agent is prepared according to the following weight percentages:

[0015]

[0016] The preparation process of the underwater static breaking agent is as follows: 14.1Kg static breaking agent, 0.405Kg ordinary Portland cement, 0.075Kg calcium chloride, 0.375Kg UWB-II flocculant and 0.045Kg polycarboxylate superplasticizer Mix, mix and disperse evenly to make an underwater static breaking agent; weigh 4.2Kg of water with an open container, pour the above-mentioned underwater static breaking agent into the water container, and stir while pouring until it becomes a uniform paste slurry; Put the pasty slurry into a straight plastic bag with the same diameter as the blast hole and wrap it with a rope lock to seal it. Then the diver puts the sealed straight plastic bag into the blast hole and compacts the blast hole with bricks.

[0017] In the present embodiment, what the static blasting of the underwater static bre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com