An RPC material and a preparing method thereof

A technology of raw materials and gypsum, which is applied in the field of RPC materials, can solve the problems of great influence of natural conditions and difficult maintenance time, etc., and achieve the effect of high early strength, easy quality control and good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

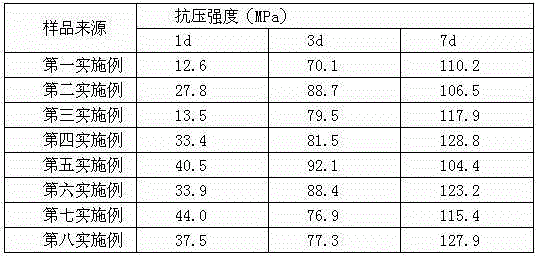

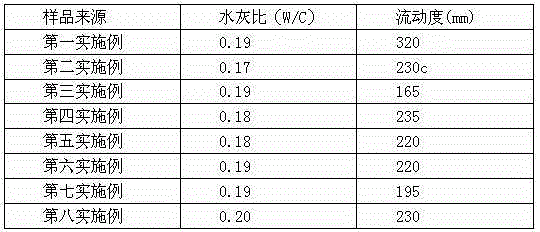

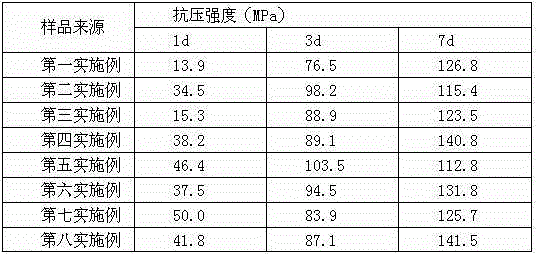

Examples

no. 1 example

[0042] The first embodiment: a low energy consumption RPC material, each ton of the low energy consumption RPC material is composed of the following raw materials:

[0043] Ordinary Portland cement 333kg, aluminate cement 100kg, silica fume 81kg, mineral powder 27kg, gypsum 33kg, coarse quartz sand 213kg, fine quartz sand 149kg, defoamer 0.3kg, steel fiber 58kg, polycarboxylate superplasticizer 5.8kg.

no. 2 example

[0044] The second embodiment: a low energy consumption RPC material, each ton of the low energy consumption RPC material is composed of the following raw materials:

[0045] Ordinary Portland cement 400kg, aluminate cement 15kg, silica fume 110kg, gypsum 32.5kg, coarse quartz sand 245kg, fine quartz sand 116kg, defoamer 0.5kg, steel fiber 74kg, polycarboxylate superplasticizer 7.1kg.

no. 3 example

[0046] The third embodiment: a low energy consumption RPC material, each ton of the low energy consumption RPC material is composed of the following raw materials:

[0047] Ordinary Portland cement 300kg, aluminate cement 150kg, silica fume 66kg, mineral powder 31kg, gypsum 29kg, coarse quartz sand 210kg, fine quartz sand 146kg, defoamer 0.35kg, steel fiber 62kg, polycarboxylate superplasticizer 5.6kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com