A heat-resistant deformation polyethylene foam plastic and its preparation method

一种聚乙烯发泡、耐热变形的技术,应用在聚乙烯发泡塑料领域,能够解决管道分离等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

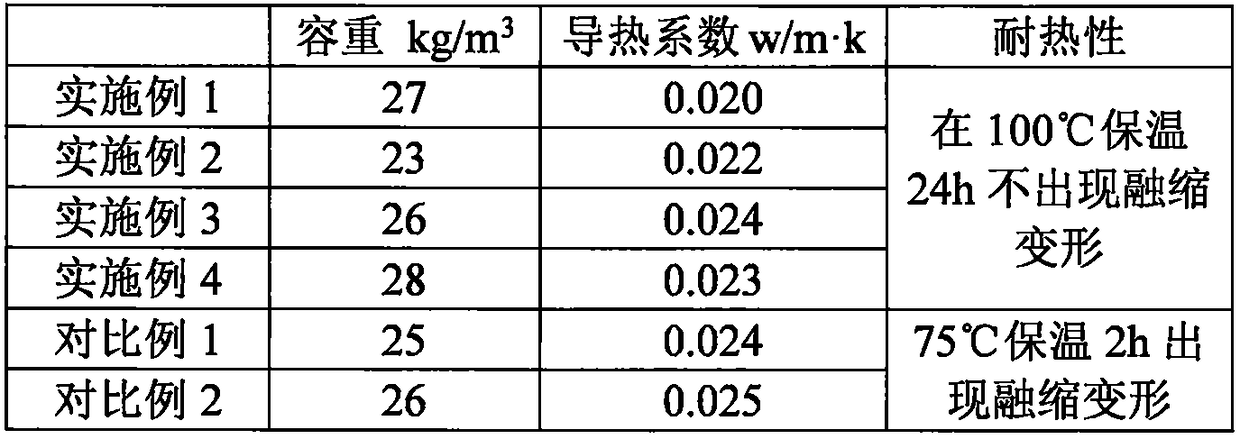

Examples

Embodiment 1

[0014] Provide a kind of polyethylene foam plastics, prepare through the following steps:

[0015] (1) Weigh each raw material according to mass percentage: bisphenol A type epoxy resin 4%, polyvinyl butyral 0.8%, diethylene triamine 0.9%, epoxy modified silicone resin 3%, potassium acetate 0.5% , Azodicarbonamide 6%, and the balance is low-density polyethylene;

[0016] (2) Add bisphenol A type epoxy resin, polyvinyl butyral, diethylene triamine, epoxy modified silicone resin, potassium acetate and low density polyethylene into the closed rubber mixing machine, at 140 ~ 150 Mix evenly at ℃, then add azodicarbonamide, mix evenly at 155-160℃, and discharge to obtain the mixed material;

[0017] (3) Put the mixed material into a mould, and then send it into a flat vulcanizer for cross-linking and foaming. The temperature is 160-175° C., the pressure is 10-12 MPa, and the holding time is 15-20 minutes;

[0018] (4) After the pressure holding is completed, the pressure drops sud...

Embodiment 2

[0020] Provide a kind of polyethylene foam plastics, prepare through the following steps:

[0021] (1) Weigh each raw material according to mass percentage: bisphenol A type epoxy resin 4.8%, polyvinyl butyral 0.6%, diethylene triamine 0.7%, epoxy modified silicone resin 3.2%, potassium acetate 0.2% , 7% of azodicarbonamide, and the balance is low-density polyethylene;

[0022] (2) Add bisphenol A type epoxy resin, polyvinyl butyral, diethylene triamine, epoxy modified silicone resin, potassium acetate and low density polyethylene into the closed rubber mixing machine, at 140 ~ 150 Mix evenly at ℃, then add azodicarbonamide, mix evenly at 155-160℃, and discharge to obtain the mixed material;

[0023] (3) Put the mixed material into a mould, and then send it into a flat vulcanizer for cross-linking and foaming. The temperature is 160-175° C., the pressure is 10-12 MPa, and the holding time is 15-20 minutes;

[0024] (4) After the pressure holding is completed, the pressure dr...

Embodiment 3

[0026] Provide a kind of polyethylene foam plastics, prepare through the following steps:

[0027] (1) Weigh each raw material according to mass percentage: bisphenol A type epoxy resin 5%, polyvinyl butyral 1.0%, diethylenetriamine 0.6%, epoxy modified silicone resin 4%, potassium acetate 0.4% , Azodicarbonamide 8%, the balance is low density polyethylene;

[0028] (2) Add bisphenol A type epoxy resin, polyvinyl butyral, diethylene triamine, epoxy modified silicone resin, potassium acetate and low density polyethylene into the closed rubber mixing machine, at 140 ~ 150 Mix evenly at ℃, then add azodicarbonamide, mix evenly at 155-160℃, and discharge to obtain the mixed material;

[0029] (3) Put the mixed material into a mould, and then send it into a flat vulcanizer for cross-linking and foaming. The temperature is 160-175° C., the pressure is 10-12 MPa, and the holding time is 15-20 minutes;

[0030] (4) After the pressure holding is completed, the pressure drops suddenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com