Novel non-woven fabric and production process thereof

A production process and technology of non-woven fabrics, applied in the decoration of textiles, textiles and papermaking, etc., can solve the problems of non-degradable, environmental pollution, poor decoration, etc., and achieve good decoration, improved bursting strength, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

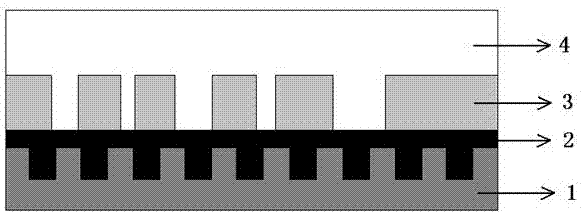

Image

Examples

Embodiment 1

[0049] A kind of direct plating method production process of the non-woven fabric with local aluminum plating effect, comprises the following steps:

[0050] (1) Step 1: Pre-coating treatment. The polypropylene resin particles are melted into a fluid state within the temperature range of 160°C-330°C, and the width of the coating film is adjusted to be 2mm smaller than the width of the non-woven fabric, so that a layer of smooth coating film is formed on the surface of the non-woven fabric. After the film passes through the water-cooled roller, the temperature is lowered, and the pre-coated non-woven fabric roll is harvested at the winding place.

[0051] (2) Step 2: Use a pre-designed flexible resin plate to print a layer of shielding oil on the surface of the pre-coated non-woven fabric, and then place the printed semi-finished product in the vacuum aluminum plating equipment. A layer of metal aluminum with a thickness of about 100 nanometers is evaporated on the surface of ...

Embodiment 2

[0055] A kind of direct plating method production process of the non-woven fabric with local aluminum plating effect, comprises the following steps:

[0056] (1) Step 1: Pre-coating treatment

[0057] Pre-coat a layer of smooth film on the surface of the non-woven fabric to form a film layer;

[0058] The more specific process is: melt polyethylene resin particles into a fluid state within the temperature range of 160°C-330°C, adjust the width of the coating film to be 2mm smaller than the width of the non-woven fabric, so that it forms a layer on the surface of the non-woven fabric. A smooth layer of coating film, the coating film passes through the water-cooled roller and cools down, and the pre-coated non-woven fabric roll is harvested at the winding place.

[0059] (2) Step 2: Partial aluminum plating to form a pattern

[0060] Use a flexible resin plate with a preset pattern to partially print shielding oil on the surface of the pre-coated non-woven fabric coating, and ...

Embodiment 3

[0065] A direct plating method production process of non-woven fabrics with partial aluminum plating effect and laser effect, comprising the following steps:

[0066] (1) Step 1: Pre-coating treatment. The polypropylene resin particles are melted into a fluid state within the temperature range of 160°C-330°C, and the width of the coating film is adjusted to be 2mm smaller than the width of the non-woven fabric, so that a layer of smooth coating film is formed on the surface of the non-woven fabric. After the film passes through the water-cooled roller, the temperature is cooled, and the pre-coated non-woven roll is harvested at the winding place. Preferably, a laser molded nickel plate is installed on the water-cooled roller, so that laser information is generated on the surface of the pre-coated layer, with a colorful laser effect.

[0067] (2) Step 2: Use a pre-designed flexible resin plate to print a layer of shielding oil on the surface of the pre-coated non-woven fabric, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com