Preparation method and application of magnesium oxide flame retardant

A flame retardant, magnesium oxide technology, applied in the direction of magnesium oxide, etc., can solve problems such as complicated operation, poor UV resistance, and corrosion of metal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

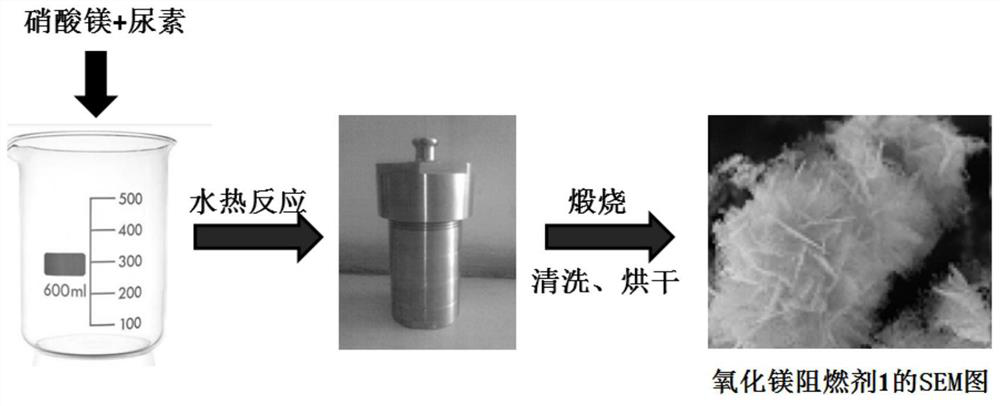

[0022] Therefore, the preparation method of the magnesium oxide flame retardant involved in the first aspect of the present invention comprises the following steps:

[0023] S1, placing an aqueous solution containing soluble magnesium salt and urea in a reactor for hydrothermal reaction to obtain a reaction product;

[0024] S2, washing, drying and calcining the reaction product to obtain a magnesium oxide flame retardant.

[0025] In the present invention, the aqueous solution comprising soluble magnesium salt and urea can be prepared by the following operations: soluble magnesium salt and urea are placed in deionized water, and ultrasonic treatment (or mechanical stirring method) is used to make it completely dissolved in Deionized water to obtain an aqueous solution containing soluble magnesium salts and urea.

[0026] The advantage of using urea as the raw material of the present invention is that other common alkali solutions (such as ammonia or sodium hydroxide, etc.) a...

Embodiment 1

[0045] Using magnesium nitrate and urea as raw materials, weigh 2.23g of magnesium nitrate and 0.90g of urea, place the weighed raw materials in 50mL of deionized water and use ultrasonic treatment to completely dissolve them in deionized water, and then dissolve the dissolved The aqueous solution of magnesium nitrate and urea (the molar ratio of magnesium nitrate and urea in the aqueous solution is 1:1, and the molar concentration of magnesium nitrate in the aqueous solution is 0.3mol / L) is transferred to an autoclave and reacted at 120°C 12 hours. After the reactor was cooled to room temperature, the product solution was transferred to a clean beaker, and the obtained reaction product was washed with deionized water and absolute ethanol respectively. After washing to neutrality, the reaction product was dried in an oven at 60°C. After drying, the reaction product was placed in a porcelain boat and transferred to a muffle furnace, calcined at 500°C for 5 hours, and after coo...

Embodiment 2

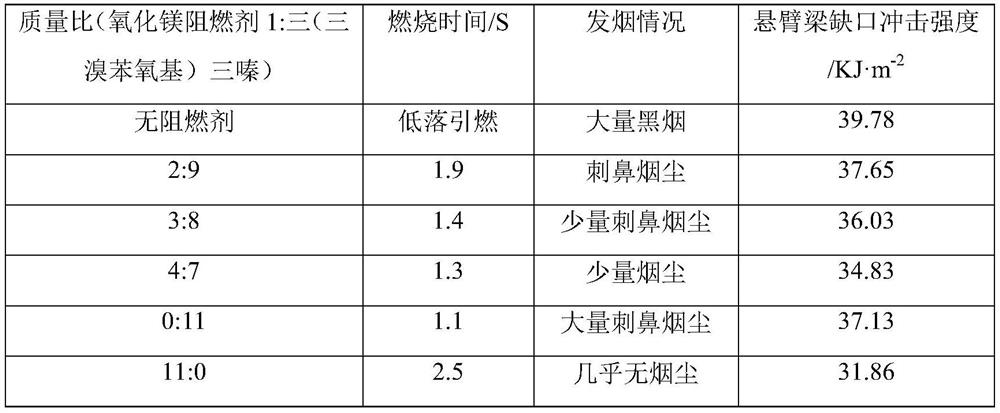

[0047] The magnesia flame retardant 1 prepared in the above-mentioned Example 1 and tris(tribromophenoxy)triazine are filled synergistically with PC / ABS alloy materials in different mass ratios, and the vertical ignition method is investigated in different mass ratios. Under the conditions of magnesia flame retardant 1 flame retardant and smoke suppression, and the mechanical properties of PC / ABS alloy materials (notched Izod impact strength as an example), the results are shown in Table 1.

[0048] Table 1

[0049]

[0050] It can be seen from Table 1 that when the magnesium oxide flame retardant 1 and tris(tribromophenoxy)triazine are used to synergistically fill the PC / ABS alloy material with a mass ratio of 3:8 and 4:7, the material performs better Excellent flame retardancy and smoke suppression ability. Especially when the magnesium oxide flame retardant 1 and tris(tribromophenoxy)triazine are synergistically filled in the PC / ABS alloy material with a mass ratio of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com