A kind of preparation method of high temperature black ceramic pigment for laser 3D printing

A technology of black ceramics and 3D printing, which is applied in the field of black ceramic pigments to achieve uniform coating thickness, strong electrostatic adsorption and easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

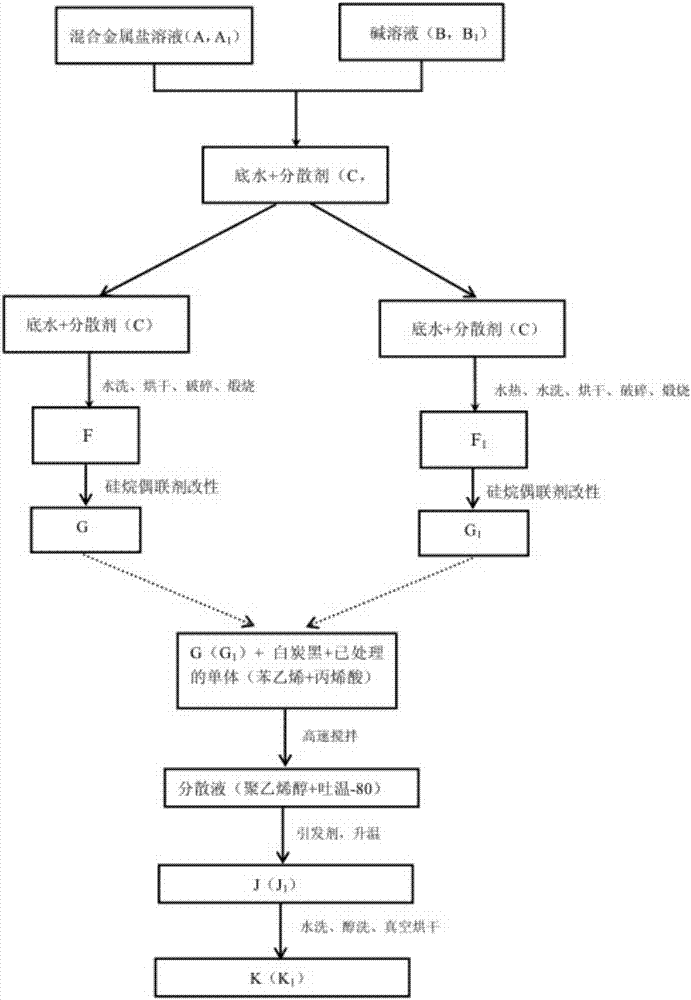

[0029] A kind of preparation method steps of high temperature black ceramic pigment for laser 3D printing is as follows:

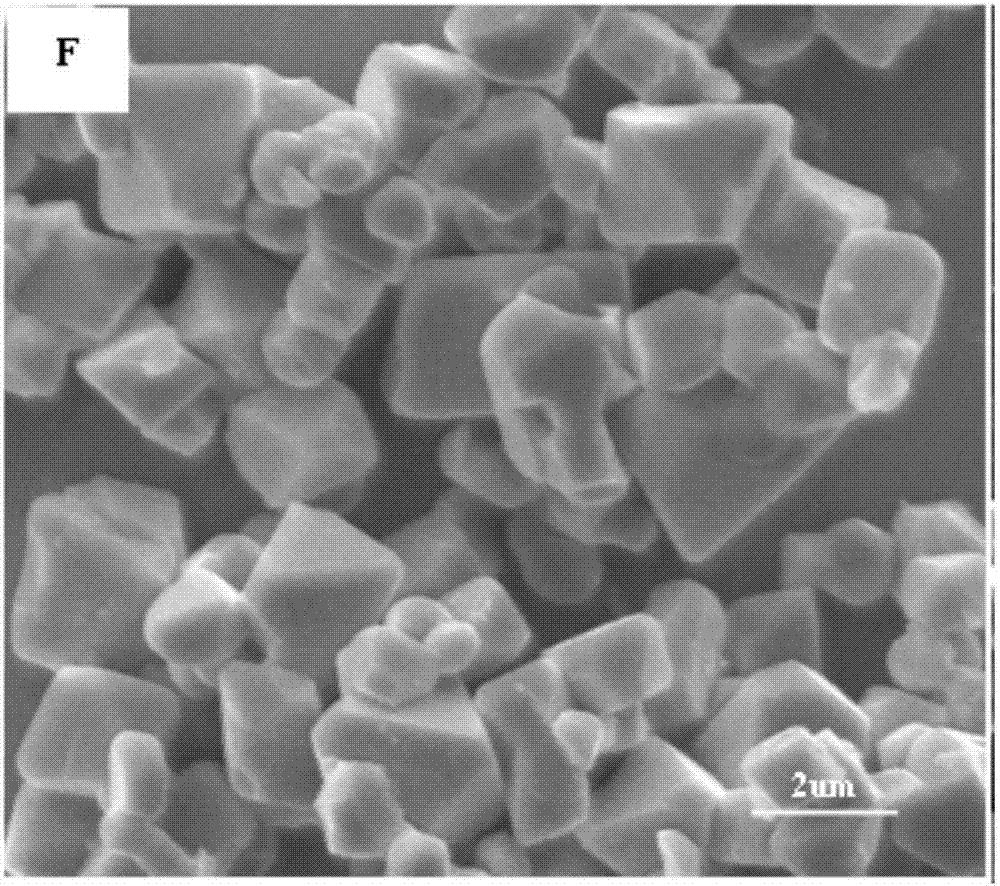

[0030] (1) Take 180gCrCl 3 ·6H 2 O, 250gFeCl 3 ·6H 2 O, 250g CoSO 4 ·7H 2 O, 70g MnSO 4 ·H 2 O, 35gNi(NO) 2 ·6H 2 Dissolve O in 5000ml of water to form A, 350g of NaOH dissolved in 5000ml of water to form B, 0.4g of polyethylene glycol-2000 dissolved in 2000ml of water to form C, drop A and B into C to keep the pH at 8, and obtain D solution, stir After 1 hour, wash D with water until no ions are washed out, dry at 120°C and pulverize through 200 meshes to obtain E, mix 3wt% NaCl and E into a crucible, calcinate at 1100°C for 60 minutes, grind with water for 10 minutes, rinse and dry , broken into F, reserved for step 2 modification treatment, its scanning electron microscope picture is as follows figure 2 , the particle crystallization is complete and the size is uniform, which is beneficial to the subsequent processing steps.

[0031] (2) Dis...

Embodiment 2

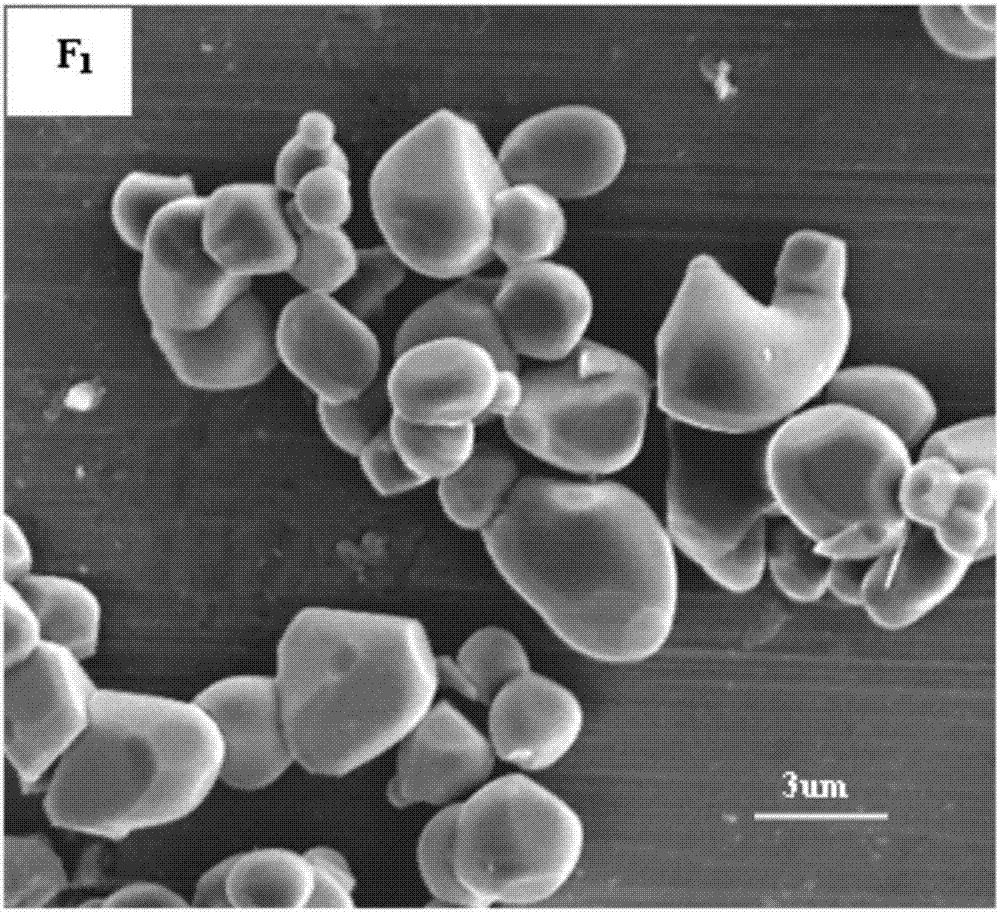

[0034] Take 200g CrCl 3 ·6H 2 O, 230g FeCl 3 ·6H 2 O, 260g CoSO 4 ·7H 2 O, 75g MnSO 4 ·H 2 O, 35gNi(NO) 2 ·6H 2 O dissolved in 5000ml water is A 1 Solution, 280gNaOH dissolved in 5000ml water is B 1 , 0.5g polyethylene glycol-2000 dissolved in 2000ml water is C 1 , put A 1 and B 1 Co-dropped in C 1 Keep the pH at 8 and record it as D 1 , then D 1 Transfer to a hydrothermal kettle at a constant temperature of 200°C for 18 hours, rinse until ion-free, dry and break, record as E 1 ; then E 1 Calcined at 900°C, milled with water for 5 minutes, dried and crushed, recorded as F 1 , reserved for step 2 modification treatment, its scanning electron microscope picture is as follows image 3 As shown, the particles are more rounded than F, the particles are more uniform, and the thermal stability is better. The subsequent steps are as described in Example 1, and the resulting product is denoted as K 1 ,Such as Figure 5 shown.

Embodiment 3

[0036] The difference between this embodiment and embodiment 1 is that A liquid is 200gCrCl 3 ·6H 2 O, 250gFeCl 3 ·6H 2 O,280gCoSO 4 ·7H 2 O, 80g MnSO 4 ·H 2 O, 35g Ni(NO) 2 ·6H 2 O is dissolved in 5000ml of water, and B liquid is 290g. The color tone of the F color material obtained in this embodiment is black and bluish, and the finally prepared laser pigment K is also blue and black when applied to laser decals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com