Hook-shaped steel core composite connecting piece prefabricated sandwiched heat insulation wallboard and manufacturing method thereof

A technology for composite connection and thermal insulation wall panels, applied in chemical instruments and methods, home walls, building components, etc. Large coefficient and other problems, to achieve the effect of enhancing overall workability, high construction efficiency, and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

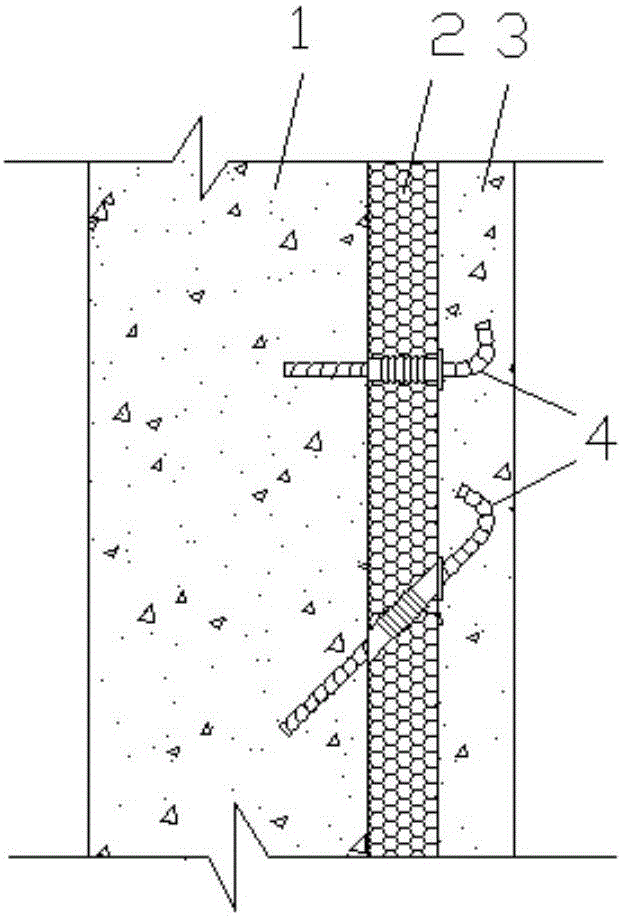

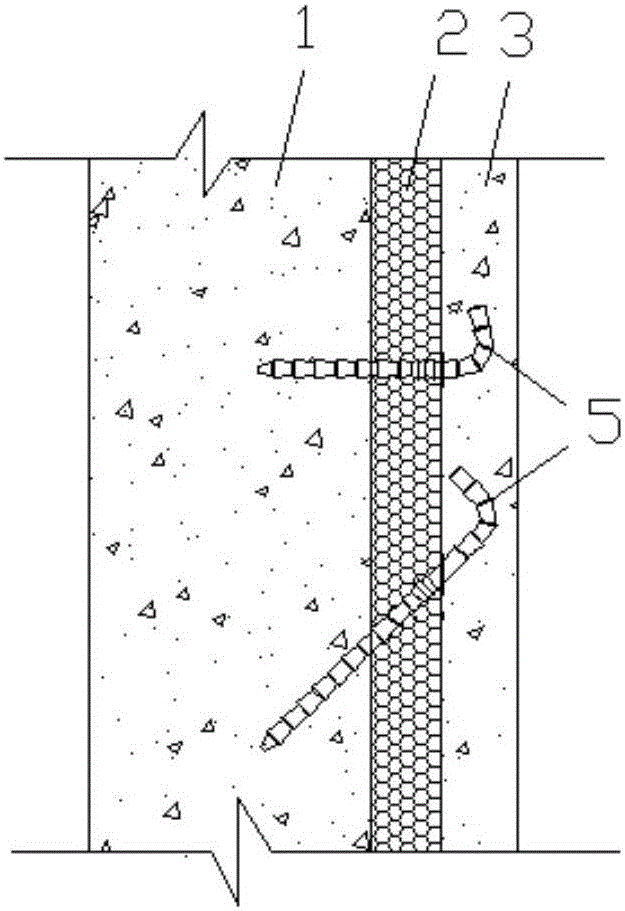

[0029] Such as Figure 1-8 As shown, a prefabricated sandwich insulation wall panel with a hook-shaped steel core composite connector has a three-layer structure, which is the inner leaf concrete wall panel 1, the insulation layer 2, and the outer leaf concrete wall panel 3. The three-layer structure is connected into a whole;

[0030] The inner leaf concrete wall panel 1 and the outer leaf concrete wall panel 3 are poured with ordinary concrete or light concrete, and the thermal insulation layer 2 is a non-flammable thermal insulation board. According to the similarities and differences in the thickness of the inner and outer leaf wall panels, Two types of center and offset;

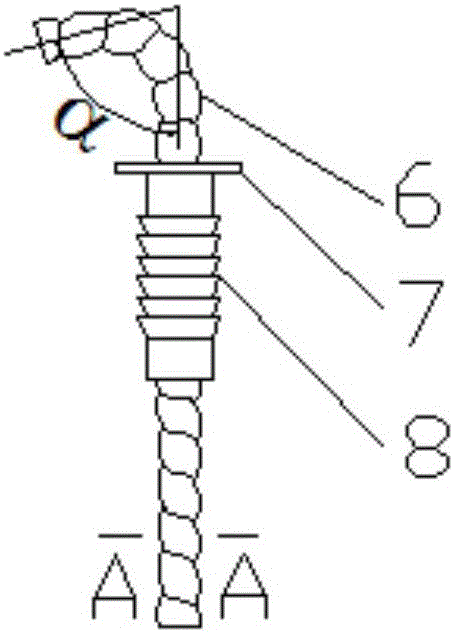

[0031] The steel core composite connector is divided into two types: one is the steel core continuous fiber composite connector 4, and the other is the steel core mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com