Exploitation system and exploitation process for deep-sea poly-metallic nodule

A polymetallic nodule and deep-sea technology, applied in mineral mining, earth square drilling, special mining, etc., can solve the problems of impeller wear, easy entanglement of cables, and low ore-carrying speed, so as to improve the service life of the pump and reduce wear and damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

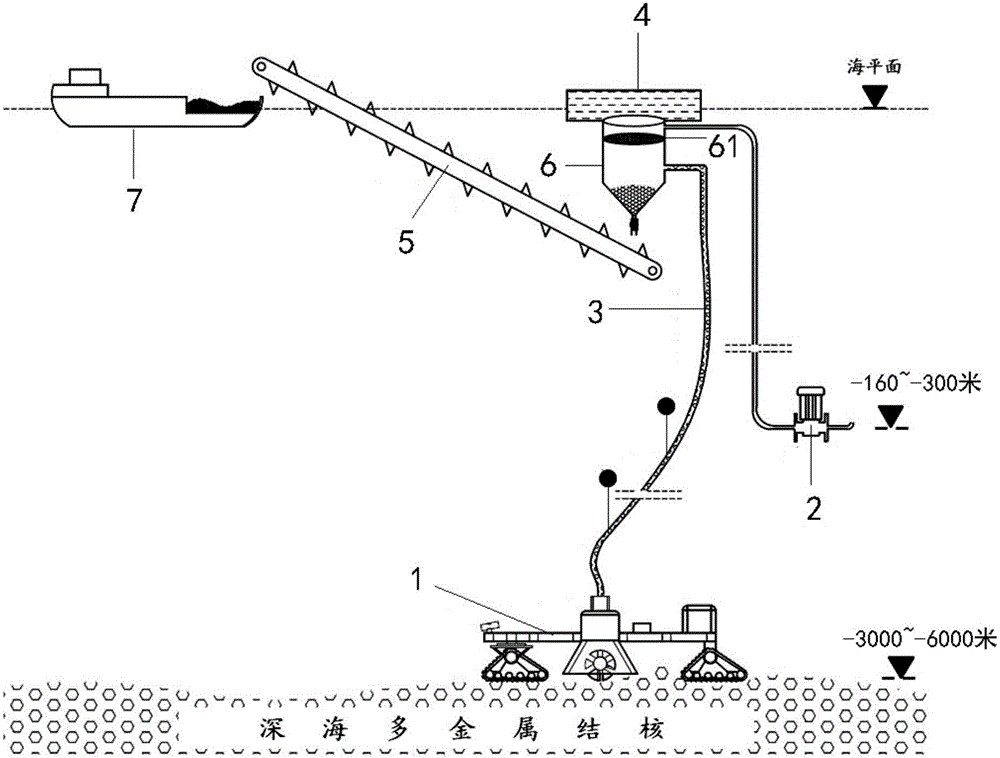

[0020] like figure 1 As shown, the mining system for deep-sea polymetallic nodules described in the present invention includes: an ore collecting subsystem, an ore lifting subsystem and a control system. Wherein, the ore collection subsystem includes a seabed mining robot 1, an umbilical cable and a mine collection tank, and the umbilical cable can provide lowering, power transportation, command control transmission, video signal transmission, etc. for the seabed mining robot 1. The seabed mining robot 1 can send the collected ore bodies together with the mud and water into the ore collection tank through the carpet type winch suction. In the present invention, the seabed mining robot 1 can adopt four-wheel crawler type independent suspension, each crawler wheel can provide driving, and has good obstacle and ditch crossing performance, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com