Cotton cloth color-fastness-to-rubbing grading standard sample and preparation method thereof

A standard sample and color fastness technology, applied in the preparation of test samples, analysis materials, measuring devices, etc., can solve the problems that it is difficult to ensure the accuracy and consistency of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

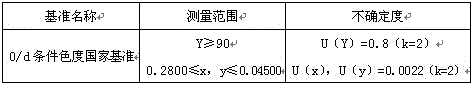

Examples

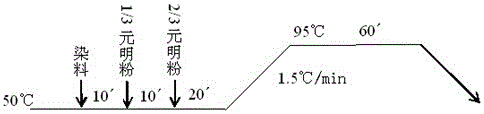

Embodiment 1

[0077] A graded standard sample of color fastness to rubbing of cotton cloth, the color fastness to dry rubbing of the standard sample is grade 2 to grade 5, and the color fastness to wet rubbing is grade 1 to grade 3. The specific preparation method is as follows:

[0078] 1) Gray cloth: Choose pure cotton woven plain gray cloth with relatively flat surface and less surface defects. The parameters of the gray cloth are: warp density 84 threads / inch, weft density 60 threads / inch, warp and weft yarn count 32Ne, square meter weight 112g / ㎡, width 90cm.

[0079] 2) Pretreatment: raw fabric preparation, singeing, desizing, scouring, bleaching;

[0080] Singeing→fire extinguishing→cloth falling, the singeing series reaches 3~4 grades.

[0081] Pre-treatment process of annealing, boiling and bleaching: the one-bath pre-treatment process of alkali oxygen is adopted, and the whiteness is required to reach more than 80%. Process flow: padding working liquid → steaming (90-95°C / 80min)...

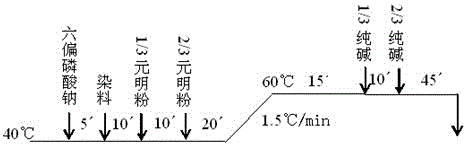

Embodiment 2

[0121] A graded standard sample of color fastness to rubbing of cotton cloth, the color fastness to dry rubbing of the standard sample is grade 2 to grade 5, and the color fastness to wet rubbing is grade 1 to grade 3. The specific preparation method is as follows:

[0122] 1) Gray cloth: Choose pure cotton woven plain gray cloth with relatively flat surface and less surface defects. The parameters of the gray cloth are: warp density 90 threads / inch, weft density 56 threads / inch, warp and weft yarn count 40Ne, square meter weight 104g / ㎡, width 90cm.

[0123] 2) Pretreatment: raw fabric preparation, singeing, desizing, scouring, bleaching;

[0124] Singeing: Gas singeing machine is adopted, and the technological process is: cloth feeding → brushing → singeing → fire extinguishing → cloth falling, and the singeing series reaches 3-4 levels.

[0125] Pre-treatment process of annealing, boiling and bleaching: the one-bath pre-treatment process of alkali oxygen is adopted, and th...

Embodiment 3

[0164] A graded standard sample of color fastness to rubbing of cotton cloth, the color fastness to dry rubbing of the standard sample is grade 2 to grade 5, and the color fastness to wet rubbing is grade 1 to grade 3. The specific preparation method is as follows:

[0165] 1) Gray cloth: Choose pure cotton woven plain gray cloth with relatively flat surface and less surface defects. The parameters of the gray cloth are: warp density 80 threads / inch, weft density 62 threads / inch, warp and weft yarn count 32Ne, square meter weight 100g / ㎡, width 90cm.

[0166] 2) Pretreatment: raw fabric preparation, singeing, desizing, scouring, bleaching;

[0167] Singeing: Gas singeing machine is adopted, and the technological process is: cloth feeding → brushing → singeing → fire extinguishing → cloth falling, and the singeing series reaches 3-4 levels.

[0168] Pre-treatment process of annealing, boiling and bleaching: the one-bath pre-treatment process of alkali oxygen is adopted, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com