One-storey barn heat dissipation temperature control system based on heat pipe technology

A technology of temperature control system and heat dissipation system, applied in the field of heat dissipation system, granary heat dissipation and heat pipe, to achieve the effect of reducing cooling capacity, energy consumption and ventilation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A heat pipe is a highly efficient heat transfer component known as a thermal "superconductor". Heat pipes have been successfully used in all areas that require heat transfer, such as spacecraft thermal control, electronics cooling, waste heat recovery, solar water heaters, stabilization of permafrost, and geothermal utilization. The heat pipe heat exchanger has a simple structure and no power parts. It transfers heat through the latent heat generated by the phase change of the working medium in the tube. Therefore, compared with other technologies, its advantage is that it can be fully automatic without consuming additional energy. work, and has a high heat transfer efficiency, and the energy saving effect is obvious.

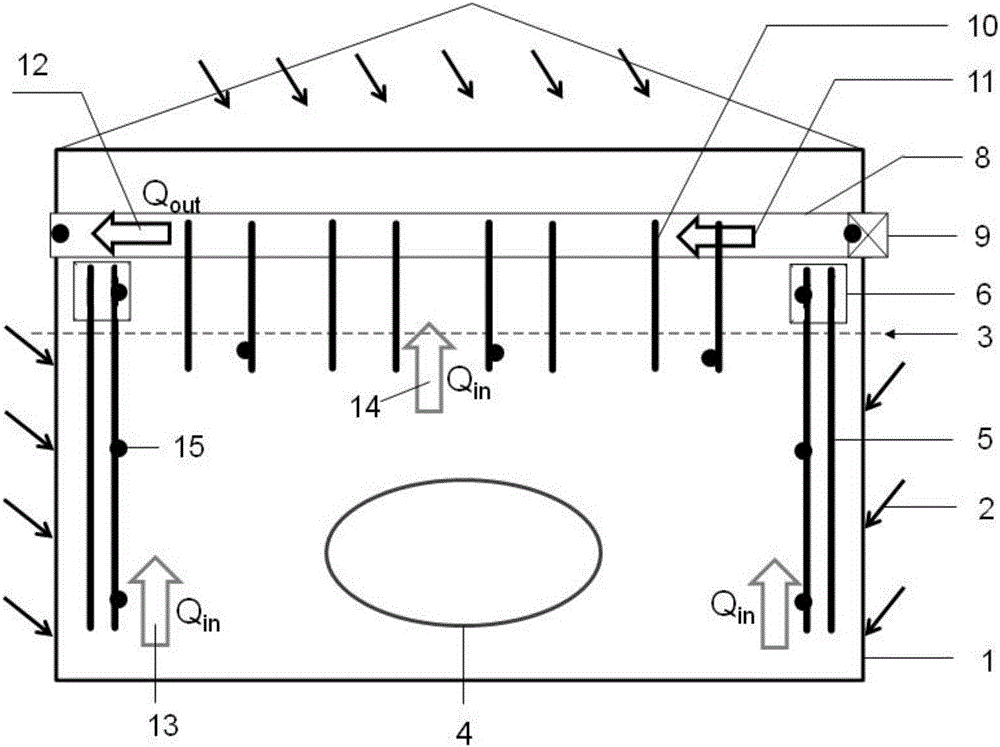

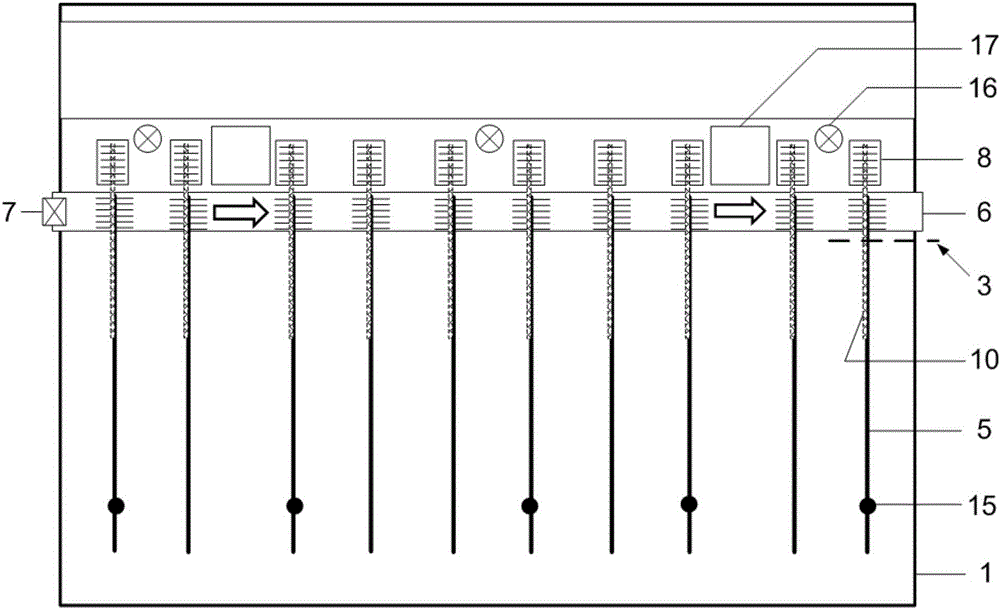

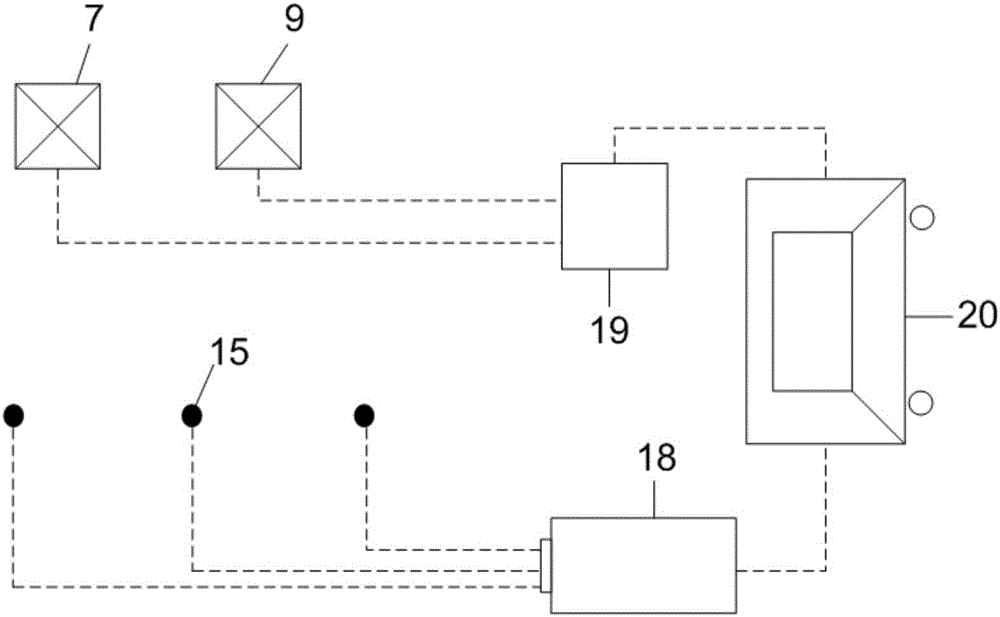

[0028] Such as figure 1 As shown, a new type of heat dissipation system for a tall one-story granary based on heat pipe technology, including heat pipes 5 along the wall, a first air duct 6, a first blower 7, a second air duct 8, a second air blower 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com