A kind of bismuth fluoride copper fluoride composite lithium battery cathode material with gradient coating layer and preparation method thereof

A technology for coating bismuth fluoride copper fluoride and bismuth fluoride copper fluoride is applied in the field of high-performance bismuth fluoride copper fluoride composite lithium battery cathode material manufacturing, and can solve lattice mismatch, coating material detachment, failure, etc. problems, to achieve the effect of improving shedding, improving electronic conductivity, and improving comprehensive electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

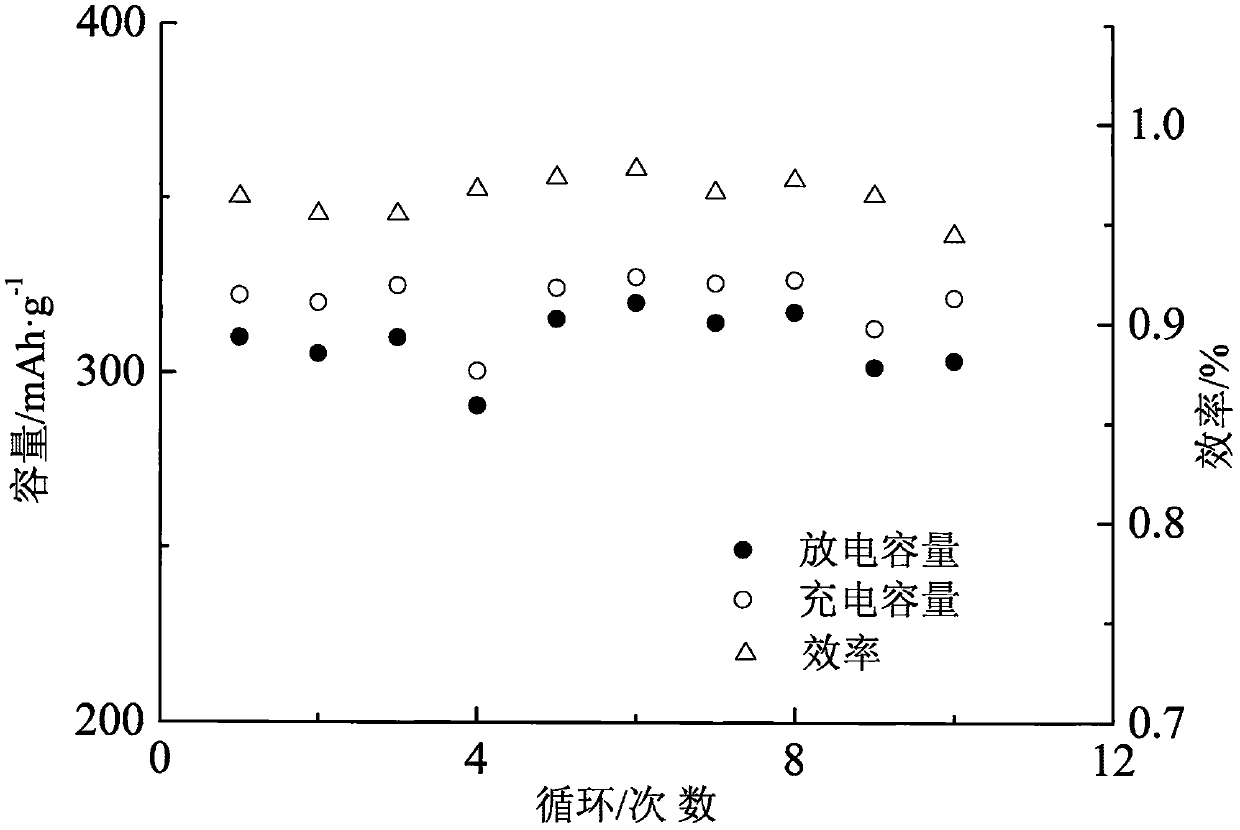

Image

Examples

Embodiment 1

[0015] Embodiment 1: the mixture of polyquaternium-15 and polyquaternium-28 with copper sulfate pentahydrate, copper sulfate pentahydrate quality 0.5% volume ratio is the mixture of polyquaternium-15 and polyquaternium-28, copper sulfate pentahydrate quality 0.5% propylene Triol and ethylene glycol are put into a ball mill after being mixed with a mixed liquid with a volume ratio of 1:1. The mass ratio of the ball mill to the material is 20:1. Ball milling is performed at a speed of 220 rpm for 3 hours. After the ball milling is completed, the material is taken out and Claim this material as material I; The volume ratio of bismuth nitrate pentahydrate, bismuth nitrate pentahydrate quality 0.9% is the mixture of polyquaternium-7 and polyquaternium-10 of 1: 1, the quality of bismuth nitrate pentahydrate 0.9% % of glycerol and ethylene glycol are mixed with a mixed liquid with a volume ratio of 1:1 and put into a ball mill. The mass ratio of the ball mill to the material is 20:1. ...

Embodiment 2

[0016] Embodiment 2: the mixture of polyquaternium-15 and polyquaternium-28 with copper sulfate pentahydrate, copper sulfate pentahydrate quality 2.6% volume ratio is the mixture of polyquaternium-15 and polyquaternium-28, copper sulfate pentahydrate quality 2.6% propylene Triol and ethylene glycol are put into a ball mill after being mixed with a mixed liquid with a volume ratio of 1:1. The mass ratio of the ball mill to the material is 20:1, and ball milled at a speed of 300 rpm for 4 hours. After the ball milling is completed, the material is taken out, and Claim this material as material I; The volume ratio of bismuth nitrate pentahydrate, bismuth nitrate pentahydrate quality 3.2% is the mixture of polyquaternium-7 and polyquaternium-10 of 1: 1, bismuth nitrate pentahydrate quality 3.2% % glycerol and ethylene glycol are mixed with a mixed liquid with a volume ratio of 1:1 and put into a ball mill. The mass ratio of the ball mill to the material is 20:1. Ball mill for 4 hou...

Embodiment 3

[0017] Embodiment 3: the mixture of polyquaternium-15 and polyquaternium-28 with copper sulfate pentahydrate, copper sulfate pentahydrate quality 5% volume ratio is the mixture of polyquaternium-15 and polyquaternium-28, copper sulfate pentahydrate quality 5% acrylic acid Triol and ethylene glycol are put into a ball mill after being mixed with a mixed liquid with a volume ratio of 1:1. The mass ratio of the ball mill to the material is 20:1, and ball milled at a speed of 400 rpm for 6 hours. After the ball milling is completed, the material is taken out, and Claim this material as material I; Bismuth nitrate pentahydrate, bismuth nitrate pentahydrate quality 4.5% volume ratio is the mixture of polyquaternium-7 and polyquaternium-10 of 1: 1, bismuth nitrate pentahydrate quality 4.5% % glycerol and ethylene glycol are mixed with a mixed liquid with a volume ratio of 1:1 and put into a ball mill. The mass ratio of the ball mill to the material is 20:1. Ball mill for 6 hours at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com