Lithium battery positive electrode material with Bi2O3/BiF<3-2x>O<x>/Zn<2+> and Mg<2+> doping bismuth fluoride layer structure and preparation method of lithium battery cathode material

A cathode material, bismuth fluoride technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as failure, lattice mismatch, detachment of coating materials, etc., to improve shedding, increase diffusion speed, and improve comprehensive electrical Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

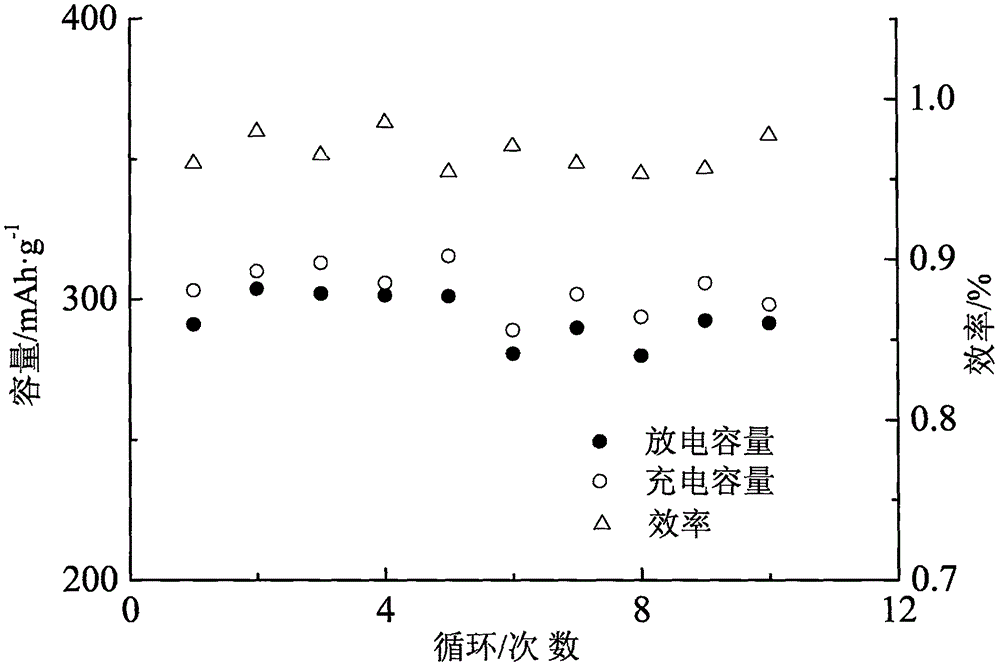

Embodiment 1

[0015] Embodiment 1: Ammonium fluoride, the amount of bismuth nitrate pentahydrate substance 0.6% zinc nitrate hexahydrate, the amount of bismuth nitrate pentahydrate substance 0.6%Mg(NO 3 ) 2 ·6H 2 O, glycerol and ethylene glycol of 0.6% of bismuth nitrate pentahydrate quality are mixed with the mixed liquid of 1: 1, polyquaternium-7 of bismuth nitrate pentahydrate quality 0.6% and put into ball mill after mixing, ball mill and material The mass ratio is 20:1, and ball milled at a speed of 200 rpm for 10 hours. After the ball milling, the material is taken out, washed with water three times, and dried in a drying oven at 100°C for 10 hours to obtain Zn 2+ , Mg 2+ doped bismuth fluoride; the Zn 2+ , Mg 2+ Doped bismuth fluoride is placed in a tube furnace with a flow rate of 2L h -1 The mixed gas of oxygen and argon with a volume ratio of 20:80 is heated up to 250°C at a rate of 2°C / min and kept at this temperature for 20 minutes; after taking out the material, it is put ...

Embodiment 2

[0016] Embodiment 2: Ammonium fluoride, the amount of bismuth nitrate pentahydrate 3.3 times the amount of bismuth nitrate pentahydrate, bismuth nitrate pentahydrate substance 3% zinc nitrate hexahydrate, the amount of 3% Mg(NO 3 ) 2 ·6H 2 O, glycerol and ethylene glycol of 3% of bismuth nitrate pentahydrate quality are mixed with the mixed liquid of 1: 1 with the volume ratio, the polyquaternium-10 of bismuth nitrate pentahydrate quality 3% mixes and put into ball mill, ball mill and material The mass ratio is 20:1, ball milled at a speed of 250 rpm for 15 hours, the material is taken out after ball milling, washed with water three times, and dried in a drying oven at 110°C for 15 hours to obtain Zn 2+ , Mg 2+ doped bismuth fluoride; the Zn 2+ , Mg 2+ Doped bismuth fluoride is placed in a tube furnace with a flow rate of 6L h -1 The mixed gas of oxygen and argon with a volume ratio of 20:80 is heated up to 300°C at a rate of 6°C / min and kept at this temperature for 30 mi...

Embodiment 3

[0017] Embodiment 3: Ammonium fluoride, the amount of bismuth nitrate pentahydrate substance 5% zinc nitrate hexahydrate, the amount of bismuth nitrate pentahydrate substance 5%Mg(NO 3 ) 2 ·6H 2 O, glycerol and ethylene glycol of 5% of bismuth nitrate pentahydrate quality are mixed with the mixed liquid of 1: 1 with volume ratio, polyquaternium-7 of bismuth nitrate pentahydrate quality 5% are mixed and put into ball mill, ball mill and material The mass ratio is 20:1, ball milled at a speed of 400 rpm for 18 hours, after the ball milling is completed, the material is taken out, washed with water three times, and dried in a drying oven at 120°C for 19 hours to obtain Zn 2+ , Mg 2+ doped bismuth fluoride; the Zn 2+ , Mg 2+ Doped bismuth fluoride is placed in a tube furnace with a flow rate of 10L h -1 A mixed gas of oxygen and argon with a volume ratio of 20:80 is heated up to 360°C at a rate of 10°C / min and kept at this temperature for 40 minutes; after the material is tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com