Fe<2>O<3>/FeF<3-2x>O<x>/Bi<3+> and La<3+> doping ferric fluoride layer structured positive electrode material of lithium battery and preparation method of positive electrode material

A positive electrode material and iron fluoride layer technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as lattice mismatch, coating material detachment, failure, etc., to improve shedding, weaken lithium ion binding, improve Effect of lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

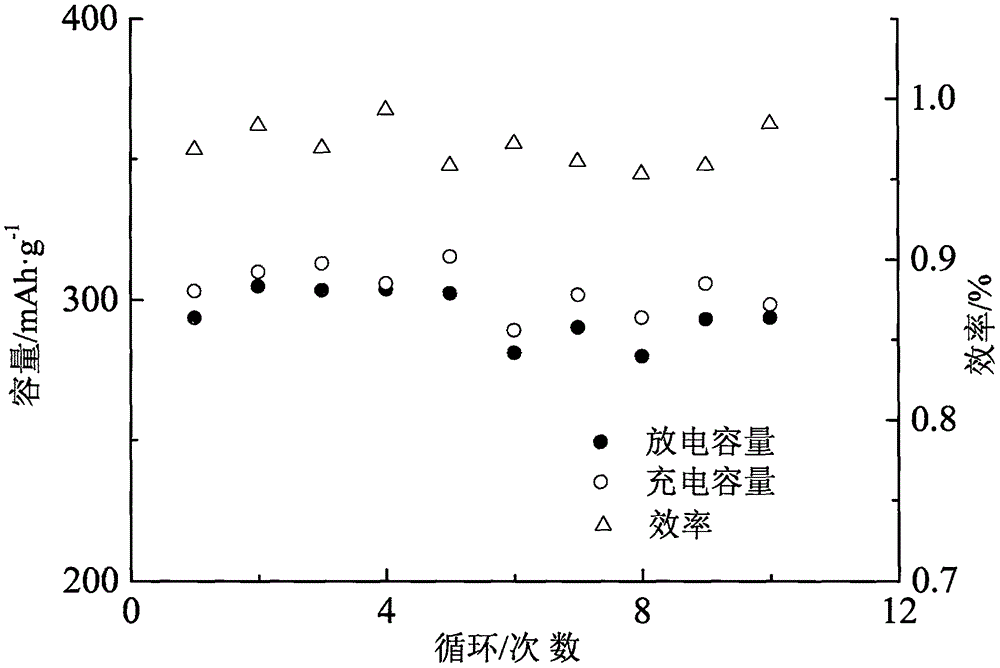

Image

Examples

Embodiment 1

[0015] Embodiment 1: Ammonium fluoride, the amount of 0.8% bismuth nitrate pentahydrate, the amount of iron nitrate nonahydrate 0.8% La(NO 3 ) 3 ·6H 2 O, glycerol and ethylene glycol of 0.8% of ferric nitrate nonahydrate quality are mixed with the mixed liquid of 1: 1 with volume ratio, polyquaternium-7 of ferric nitrate nonahydrate quality 0.8% are mixed and put into ball mill, ball mill and material The mass ratio is 20:1, ball milled at a speed of 200 rpm for 10 hours, the material is taken out after ball milling, washed with water three times, and dried in a drying oven at 100°C for 10 hours to prepare Bi 3+ , La 3+ doped with ferric fluoride; the Bi 3+ , La 3+ Doped ferric fluoride is put into the tube furnace, and the flow rate is 1.5L h -1 A mixed gas of oxygen and argon with a volume ratio of 10:90 is heated up to 180°C at a rate of 2°C / min and kept at this temperature for 10 minutes; after the material is taken out, it is put into an air atmosphere and the temper...

Embodiment 2

[0016] Embodiment 2: Ammonium fluoride, the amount of 3% bismuth nitrate pentahydrate, the amount of 3% La(NO 3 ) 3 ·6H 2 O, glycerol and ethylene glycol of 3% of ferric nitrate nonahydrate quality are mixed with the mixed liquid of 1: 1, the polyquaternium-7 of 3% of ferric nitrate nonahydrate quality by volume and put into ball mill, ball mill and material The mass ratio is 20:1, ball milled at a speed of 300 rpm for 15 hours, after the ball milling is completed, the material is taken out, washed with water three times, and dried in a drying oven at 110°C for 15 hours to prepare Bi 3+ , La 3+ doped with ferric fluoride; the Bi 3+ , La 3+ Doped ferric fluoride is placed in a tube furnace with a flow rate of 5L h -1 The mixed gas of oxygen and argon with a volume ratio of 10:90 is heated up to 220°C at a rate of 5°C / min and kept at this temperature for 15 minutes; after the material is taken out, it is put into an air atmosphere and the temperature is constant. Keep it i...

Embodiment 3

[0017] Embodiment 3: Ammonium fluoride, the amount of 4.5% bismuth nitrate pentahydrate, the amount of iron nitrate nonahydrate 4.5% La (NO 3 ) 3 ·6H 2 O, glycerol and ethylene glycol of 4.5% of ferric nitrate nonahydrate quality are mixed with the mixed liquid of 1: 1 with the volume ratio, polyquaternium-10 of 4.5% of ferric nitrate nonahydrate quality is mixed and put into ball mill, ball mill and material The mass ratio is 20:1, ball milled at a speed of 400 rpm for 20 hours, the material is taken out after ball milling, washed with water three times, and dried in a drying oven at 120°C for 20 hours to prepare Bi 3+ , La 3+ doped with ferric fluoride; the Bi 3+ , La 3+ Doped ferric fluoride is placed in the tube furnace, and the flow rate is 10L h -1 The mixed gas of oxygen and argon with a volume ratio of 10:90 is heated up to 260°C at a rate of 8°C / min and kept at this temperature for 25 minutes; after the material is taken out, it is put into an air atmosphere and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com