Plasma sterilization device for flexible discharge electrode structure

A disinfection and plasma technology, applied in the direction of plasma, disinfection, water supply equipment, etc., can solve the problem of excessive ozone, achieve the effect of increasing the area of action, large area, and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

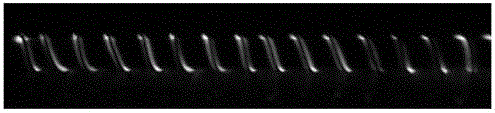

[0053] Figure 4 This is the case where one electrode is a flexible body. The flexible electrode a1 uses a cylindrical carbon fiber wire wrapped with an insulating medium (polytetrafluoroethylene). The other rigid electrode a2 is made of stainless steel tube and wrapped with insulating medium a3. The carbon fiber wire is wound on the stainless steel tube electrode in a spiral manner. The pitch (coil interval) is set according to the actual discharge area required, so that the two electrodes form a relatively uniform interface .

[0054] In particular, when the flexible electrode a1 uses bare carbon fiber wires (without additional insulating layer), a single-sided dielectric barrier discharge can be formed, which can effectively reduce the initial discharge voltage, and the amount of ozone generated is greatly reduced. Connecting this electrode structure to the power supply system of the embodiment, and placing the electrodes on the treated objects such as bed sheets and quil...

Embodiment 2

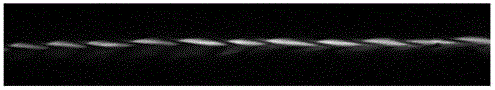

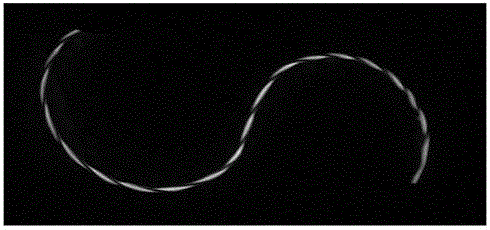

[0057] Image 6 This is the case where both electrodes are flexible bodies. The two flexible electrodes can both use wires whose diameter is wrapped with insulating medium b3 (polytetrafluoroethylene), at least one electrode conductor is made of carbon fiber material, and the wire b1 is bent as follows according to actual needs Image 6 In the desired shape, the wire b2 is helically wound on the wire b1, and the whole remains in the shape of the wire b1. It is also possible to twist the wires b1 and b2 together first, and then fold them into the desired shape. In particular, when one of the wires b1 and b2 is a bare carbon fiber wire, a single-sided dielectric barrier discharge is also formed, which can effectively reduce the initial discharge voltage, have better uniformity, and greatly reduce the amount of ozone generated. In the hospital ward, the schematic diagram of the disinfection and sterilization device system constructed by the flexible electrode combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com