Heat-curable rubber compositions with plastisol-like rheology

A composition, thermosetting technology, applied in the field of sealing or bonding parts, coating, can solve problems that cannot be used for structural adhesive bonding, high cost, strength constraints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0146] The type of heat source is in principle immaterial, so that heat can be supplied, for example, by means of a thermal blower, by microwave or infrared radiation, by magnetic induction or by heating clamps. In the technical field of vehicle construction and in the use of related production methods, it is particularly advantageous that the curing of the composition according to the invention takes place while the vehicle is passing through an oven in order to cure the cathodic impregnation coating or the baking varnish coating, so that it is possible to omit separate heating step.

[0147] Then for the curing reaction of the composition and optionally the foaming reaction, various painting oven treatment temperatures are available, i.e. in the temperature range between 80°C-240°C for about 10-35 minutes; The car body or part is preferably passed through a so-called "EC oven" for curing the composition according to the invention, ie at a temperature between 160°C and 200°C....

Embodiment

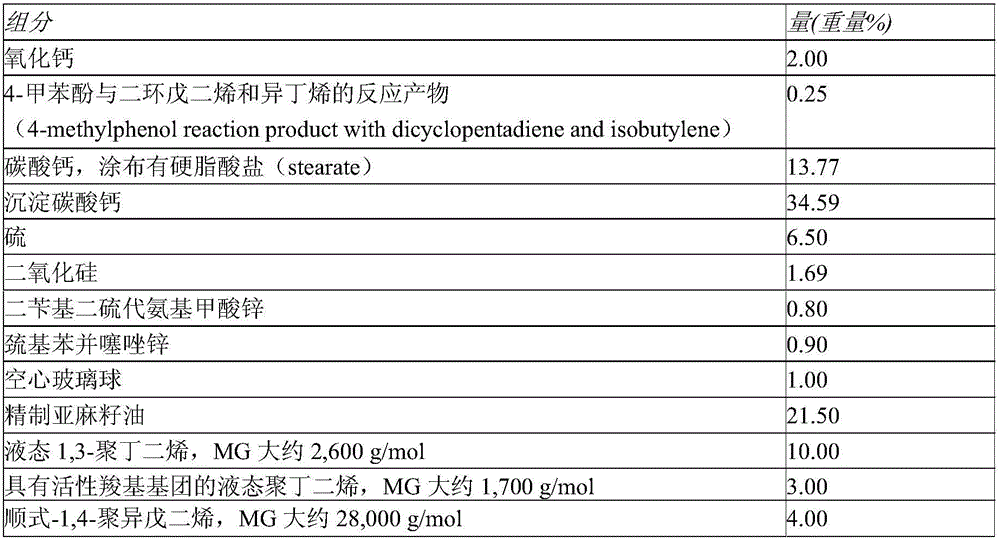

[0169] Composition 1

[0170]

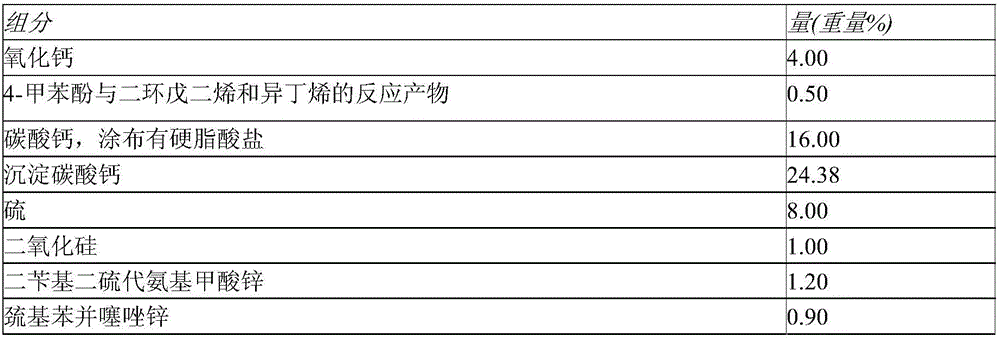

[0171] Composition 2

[0172]

[0173]

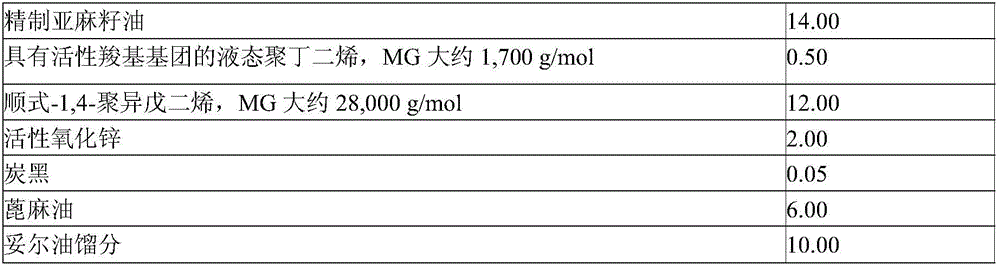

[0174] Composition 3

[0175] components

Amount (weight%)

4.00

Titanium dioxide

0.50

Calcium carbonate, coated with stearate

16.50

Precipitated calcium carbonate

31.65

5.00

Zinc dibenzyl dithiocarbamate

2.20

0.90

Refined Linseed Oil

25.40

Liquid polybutadiene with reactive carboxyl groups, MG approx. 1,700 g / mol

5.00

cis-1,4-polyisoprene, MG about 54,000 g / mol

4.80

3.00

0.05

1.00

[0176] Composition 4

[0177] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com