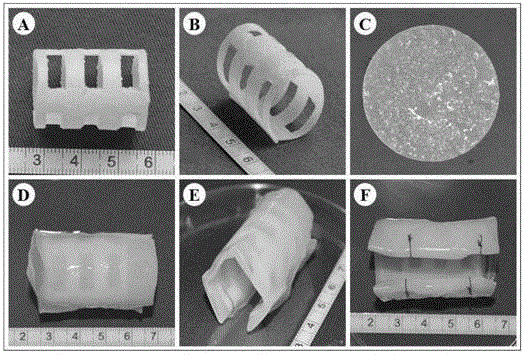

Method for constructing tissue engineered cartilages in vivo

A tissue engineering and cartilage technology, applied in the field of biological tissue, can solve the problems of poor mechanical strength and no specific shape of cartilage, and achieve the effect of improving the success rate, avoiding adverse reactions, and facilitating the precise control and maintenance of shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] S1. Isolation and culture of sheep ear chondrocytes;

[0049] S1.1. Aseptically cut goat ear cartilage pieces about 2cm×2cm in size, and cut them into 1mm pieces 3 Cartilage blocks were washed repeatedly with chloramphenicol solution, added 3 times the volume of 0.25% trypsin, placed in a constant temperature water bath shaker at 37°C for digestion for 30 minutes to remove fibrous connective tissue outside the cartilage tissue, and then washed with phosphate buffered saline (PBS ) was washed 3 times, the cartilage pieces were precipitated, and trypsin was removed;

[0050] S1.2. Add 0.15% type II collagenase, prepare the corresponding concentration with chondrocyte culture medium, filter with a needle filter of 0.22 microns, use immediately, and digest in a constant temperature water bath shaker at 37°C for 6-8 hours;

[0051] S1.3. Until most of the cartilage pieces are digested, the obtained digestion solution is filtered with a 100-micron cell strainer, centrifuged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com