A preparation method of polyphenylene sulfone solvent-resistant nanofiltration membrane containing modified microporous spheres

A technology of polyphenylene sulfone and microporous balls, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane performance degradation and difficulty in dispersion, and achieve high selectivity and improved separation performance , high-throughput effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a ZIF-8 type microporous ball-filled polyphenylsulfone membrane used for nanofiltration and separation of organic solutions and a preparation method thereof. First, the ZIF-8 type microporous spheres are synthesized, and then the ZIF-8 type microporous spheres are added to the polyphenylsulfone membrane preparation solution in a certain proportion, and the composite membrane is obtained after post-processing.

[0024] Synthesis of ZIF-8 type microporous ball: 1.95g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of methanol to obtain a zinc salt solution, 4.9 g of 2-methylimidazole was dissolved in 100 mL of methanol to prepare a 2-methylimidazole solution, and 1.0 g of polyacrylate carboxyl microspheres were added to 100 mL of methanol to make the dispersion uniform. The microsphere dispersion was mixed with the zinc salt solution, stirred in a constant temperature oscillator at 30°C and 150r / min for 24 hours, and 2-methylimidazole solution was added and...

Embodiment 1~4

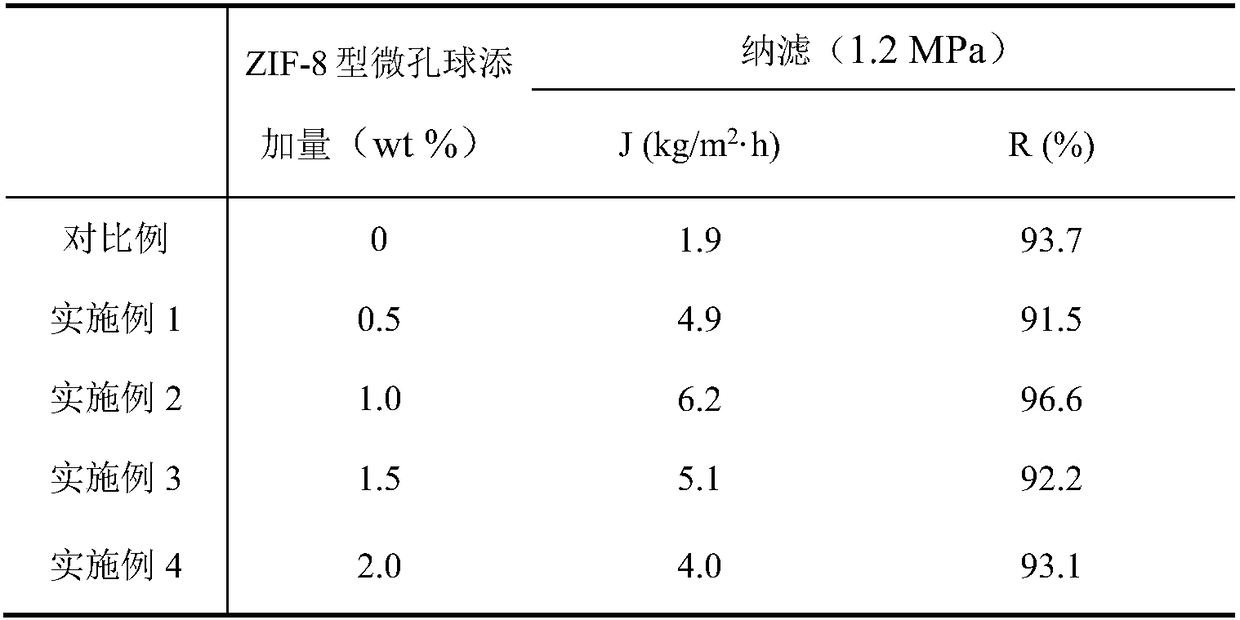

[0036] Add nanofiltration membrane to ZIF-8 type microporous spheres: Weigh an appropriate amount of ZIF-8 type microporous spheres and add N-methylpyrrolidone to ultrasonically disperse them until they are uniform, respectively. 0.5-2.0wt% is added to the polyphenylsulfone membrane-forming solution, and the mixture is uniformly stirred and then used for the phase inversion method to prepare the ZIF-8 type microporous sphere modified polyphenylsulfone membrane. The other film preparation steps are the same as the comparative example. The separation performance is shown in Table 1. The permeation flux first increases and then decreases as the content of ZIF-8 type microporous spheres increases, and the rejection rate first increases and then decreases in the same trend; the addition amount of ZIF-8 type microporous spheres is 0.5~2.0 At wt%, both flux and rejection can be improved.

[0037] Table 1 Separation performance of ZIF-8 type microporous sphere modified polyphenylsulfone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com