Food transport package device

A technology for food and positioning plate, applied in the field of machinery, can solve the problems such as the inability to guarantee the dryness of the food storage environment, the inability to avoid the food extrusion damage, the accelerated food deterioration, etc., to achieve the effects of preventing damage, reducing damage and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

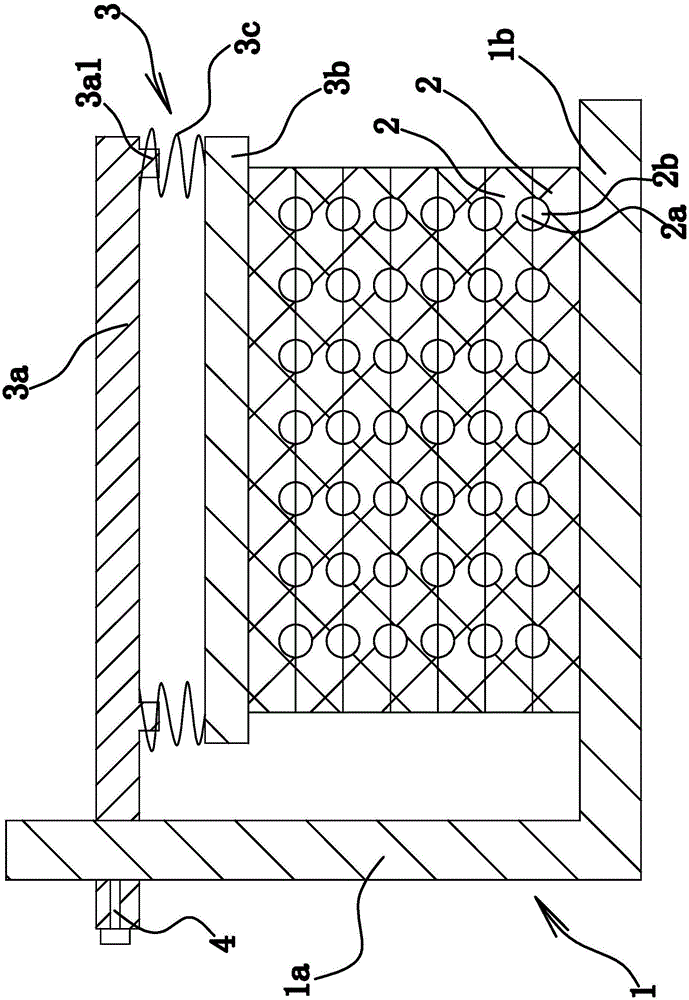

[0024] as shown in the picture 1 As shown, the food transport packaging device consists of a bracket 1 ,Positioning plate 2 , platen 3 and so on. Among them, the positioning board 2 Made of sponge material.

[0025] Specifically, the bracket 1 presented L shape, the bracket 1 Including vertically arranged connections 1a and horizontal support 1b , connecting part 1a and support 1b Both are in the form of a plate and both have an integrated structure.

[0026] Positioning plate 2 There are several blocks and they are all set on the bracket 1 Inside. as shown in the picture 1 As shown, several positioning boards 2 Stacked from top to bottom, each positioning board 2 The positions are all right, and the positioning plate 2 with support 1b parallel.

[0027] Positioning plate at the bottom 2 underside and support 1b The upper side of the 2 There is a pressure plate on the upper side of the 3 . Two adjac...

Embodiment 2

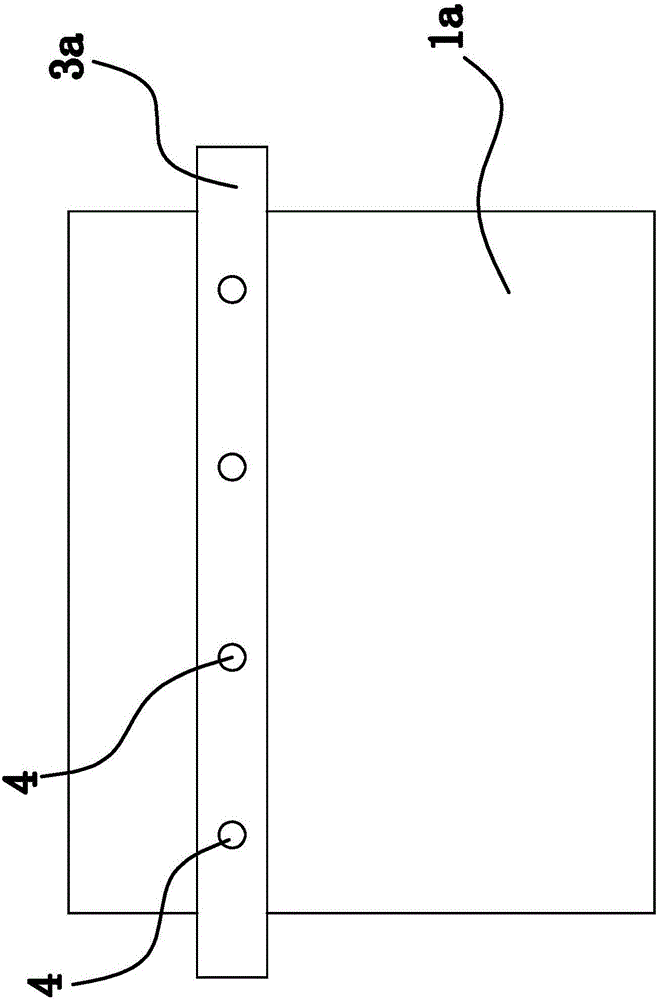

[0032] The structure and principle of the second embodiment are basically the same as that of the first embodiment, the difference lies in: the connecting part 1a The side wall runs through the horizontal direction with the second elongated chute, and the length extension direction of the second chute is consistent with the vertical direction. There is a slider 2 inside the chute 2, and the two inner walls of the chute 2 in the length direction are respectively against the two ends of the slider 2, and one side of the slider 2 is in contact with the slide plate. 3a phase fixed. The detachable locking mechanism includes a bolt 2 and a threaded hole 2 that runs through one of the inner walls of the chute 2 in the length direction. There are several threaded holes 2 and are evenly distributed along the length direction of the chute. threaded hole 2, and the end of the bolt 2 can closely abut against the slider 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com