Carbon/carbon composite material preform and preparation method thereof

A technology of carbon composite materials and carbon fiber prefabrication, applied in the field of materials science, can solve the problems of complex preparation process and high cost, and achieve the effect of simple equipment, low cost and short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

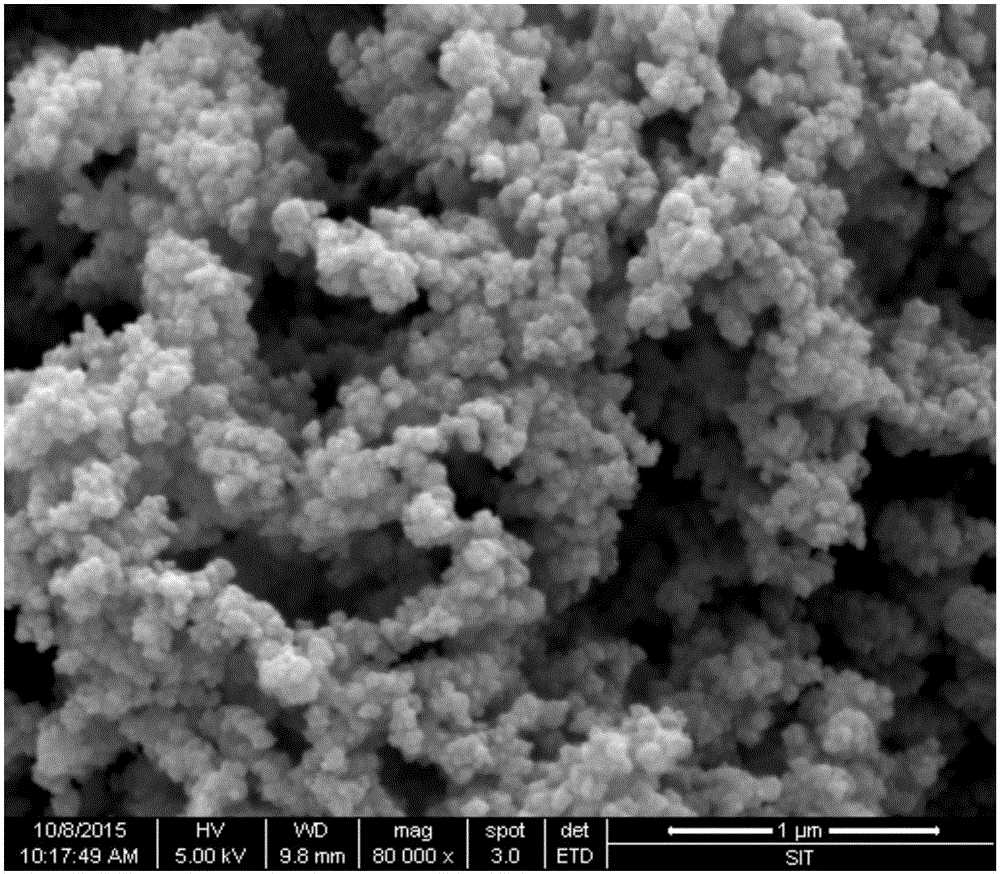

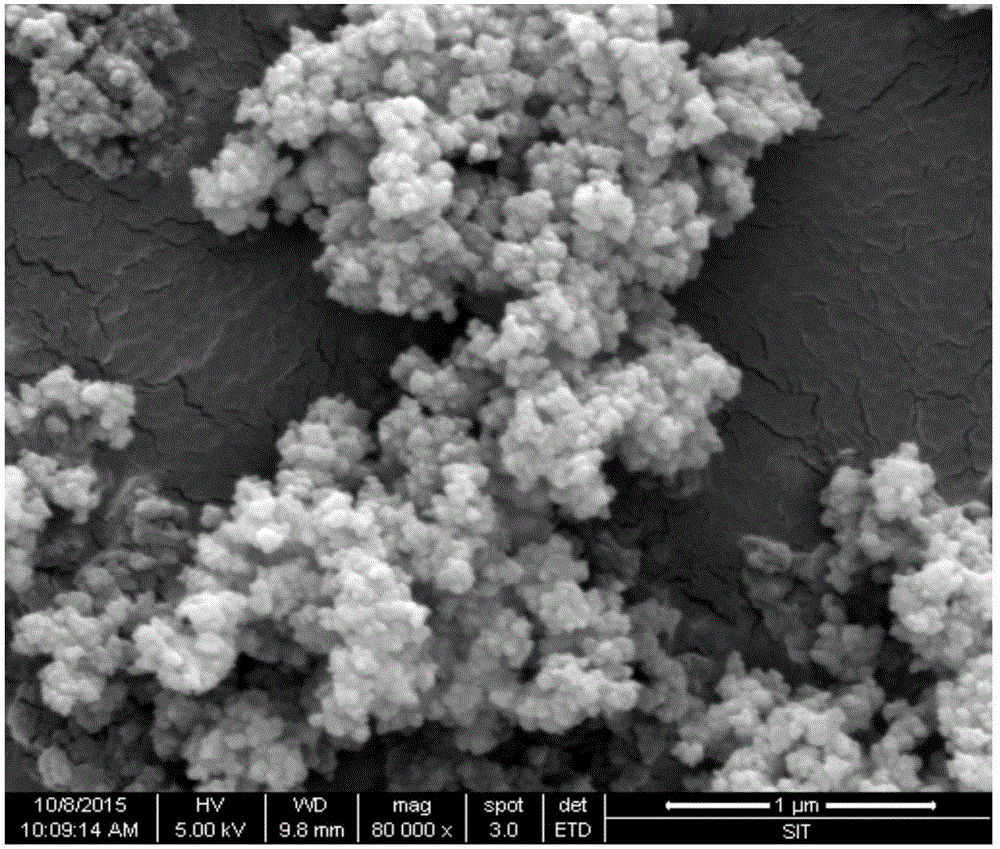

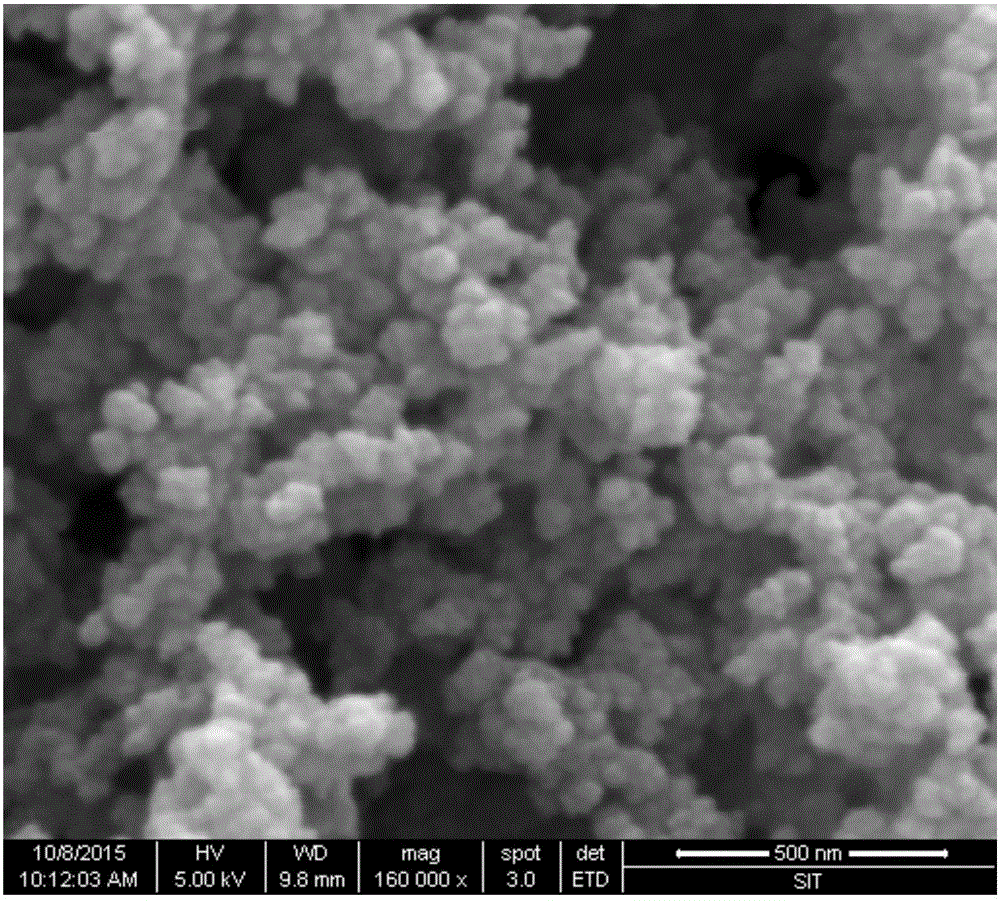

Image

Examples

Embodiment 1

[0039] (1) First prepare the dispersion, the weight ratio of the dispersant polyethylene oxide, methyl hydroxypropyl cellulose ether and distilled water in the dispersion is 1:1:2000, and then add short carbon fibers with a length of 6mm to the dispersion Among them, the weight ratio of the two is 1:400, wherein the weight of the short carbon fiber is 9g, and finally the above-mentioned mixture is stirred in a magnetic stirrer for 8h to evenly disperse the short carbon fiber in the dispersion liquid, and the stirring speed is 800 rpm;

[0040] (2) Pour the above mixture into a container with a certain geometric shape, the geometric shape of the container is determined according to the shape of the prefabricated body, let the short carbon fibers settle for 0.5h, and suck out the supernatant;

[0041] (3) Place the above-mentioned container in a drying oven, and dry it at 110° C. for 10 hours to obtain 8.79 g of a preformed short carbon fiber preform;

[0042] (4) In 200g of n-p...

Embodiment 2

[0046] (1) First prepare the dispersion, the weight ratio of the dispersant polyethylene oxide, methyl hydroxypropyl cellulose ether and distilled water in the dispersion is 1:1:2000, and then add short carbon fibers with a length of 6mm to the dispersion Among them, the weight ratio of the two is 0.5:400, wherein the weight of the short carbon fiber is 4.5g, and finally the above-mentioned mixture is stirred in a magnetic stirrer for 6h to evenly disperse the short carbon fiber in the dispersion liquid, and the stirring speed is 600 rpm;

[0047] (2) Pour the above mixture into a container with a certain geometric shape, the geometric shape of the container is determined according to the shape of the prefabricated body, let the short carbon fibers settle for 0.5h, and suck out the supernatant;

[0048] (3) Place the above-mentioned container in a drying oven, and dry at 110° C. for 10 hours to obtain a preliminary formed short carbon fiber prefabricated body;

[0049] (4) Add...

Embodiment 3

[0053] (1) First prepare the dispersion, the weight ratio of the dispersant polyethylene oxide, methyl hydroxypropyl cellulose ether and distilled water in the dispersion is 1:1:2000, and then add short carbon fibers with a length of 9mm to the dispersion Among them, the weight ratio of the two is 1:400, wherein the weight of the short carbon fiber is 9g, and finally the above-mentioned mixture is stirred in a magnetic stirrer for 7h to evenly disperse the short carbon fiber in the dispersion liquid, and the stirring speed is 600 rpm;

[0054] (2) Pour the above mixture into a container with a certain geometric shape, the geometric shape of the container is determined according to the shape of the prefabricated body, let the short carbon fibers settle for 0.5h, and suck out the supernatant;

[0055] (3) Place the above-mentioned container in a drying oven, and dry at 110° C. for 10 hours to obtain a preliminary formed short carbon fiber prefabricated body;

[0056] (4) Add m-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com