Colorless and transparent low dielectric constant polyimide film and preparation method thereof

A technology of polyimide film and polyamic acid, which is applied in the field of colorless transparent low dielectric constant polyimide film and its preparation, polyimide material, can solve problems such as difficult to achieve, and achieve simple technical process , easy industrial production, and the effect of reducing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

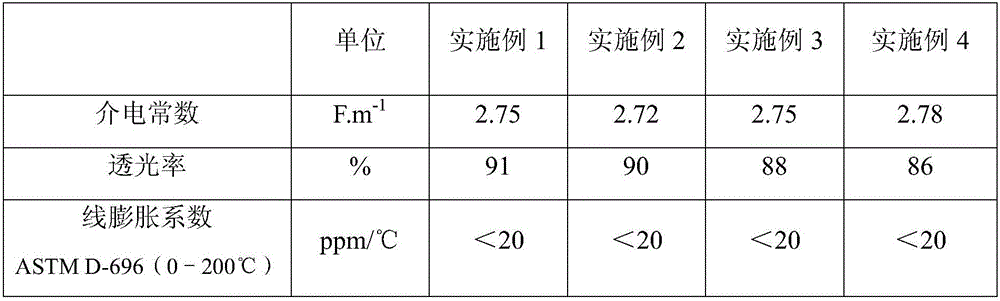

Examples

Embodiment 1

[0019] Add 2,2'-bis[4-(4-aminophenoxybenzene)]hexafluoropropane and 4,4'-(hexafluoroisopropene)diphthalic anhydride at a molar ratio of 1:1 to N,N' -In dimethylacetamide (DMAc), control the solution mass concentration to 15%, control the solution temperature to 40°C, and fully stir for 4 hours to fully react the monomers to obtain a polyamic acid solution with a viscosity of 28000Pa.s, and the viscosity within 2 hours The value does not vary by more than 2%.

[0020] Referring to the polyimide salivation process mentioned in the specific embodiment of the Chinese patent (application number CN 200610039940.7), the composite solution obtained in step 3 was made into a polyimide film with a thickness of 12.5 μm.

Embodiment 2

[0022] Add 2,2'-bis[4-(4-aminophenoxybenzene)]hexafluoropropane and 4,4'-(hexafluoroisopropene)diphthalic anhydride at a molar ratio of 1:1 to N,N' - In dimethylformamide (DMF), control the solution mass concentration to 20%, the solution temperature to 30°C, and fully stir for 5 hours to fully react the monomers to obtain a polyamic acid solution with a viscosity of 32000Pa.s, and the viscosity value within 2 hours Changes do not exceed 2%.

[0023] Referring to the polyimide salivation process mentioned in the specific embodiment of the Chinese patent (application number CN 200610039940.7), the composite solution obtained in step 3 was made into a polyimide film with a thickness of 15 μm.

Embodiment 3

[0025] Add 2,2'-bis[4-(4-aminophenoxybenzene)]hexafluoropropane and 4,4'-(hexafluoroisopropene) diphthalic anhydride at a molar ratio of 1:1 to N'-formaldehyde In NMP, the mass concentration of the solution was controlled at 25%, the solution temperature was 50°C, and fully stirred for 4 hours to fully react the monomers to obtain a polyamic acid solution with a viscosity of 36000 Pa.s, and the change in viscosity value within 2 hours did not exceed 2 %.

[0026] Referring to the polyimide salivation process mentioned in the specific embodiment of the Chinese patent (application number CN 200610039940.7), the composite solution obtained in step 3 was made into a polyimide film with a thickness of 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com