Test apparatus and method for evaluating erosion corrosion of oil and gas pipelines at high flow rates

A technology for scouring corrosion and oil and gas pipelines, applied in the field of oil and gas pipeline corrosion evaluation, can solve problems such as unsuitable for laboratory research, inconvenient operation, and high system operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Corrosion Behavior of Carbon Steel Pipe Lines in Oil and Gas Produced Water at High Flow Rates

[0046] Step 1, sample preparation: the carbon steel pipe section is processed into a smooth sample, the surface of the sample is polished step by step with 200#, 400#, 800# and 1200# sandpaper, and the size of the sample is measured and weighed;

[0047] Step 2, simulated solution preparation: in parts by mass, 50 parts of NaCl, 23 parts of MgSO 4 , 25 parts of CaCl 2 , 10 parts of NaHCO 3 and 2 servings of KHCO 3 Mix evenly with 10 liters of deionized water to prepare a simulated solution;

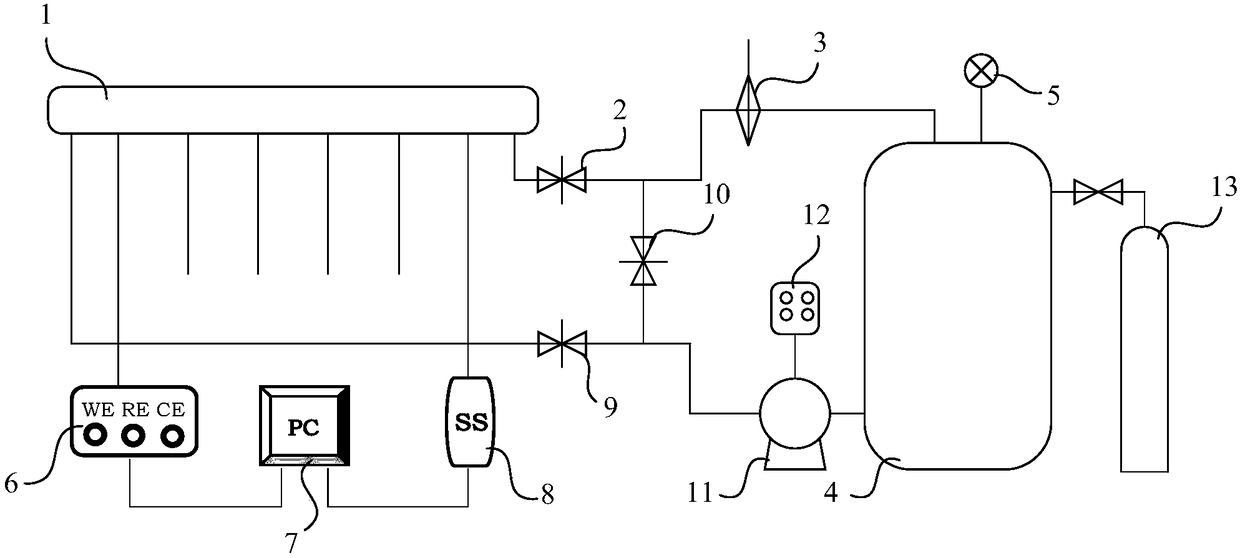

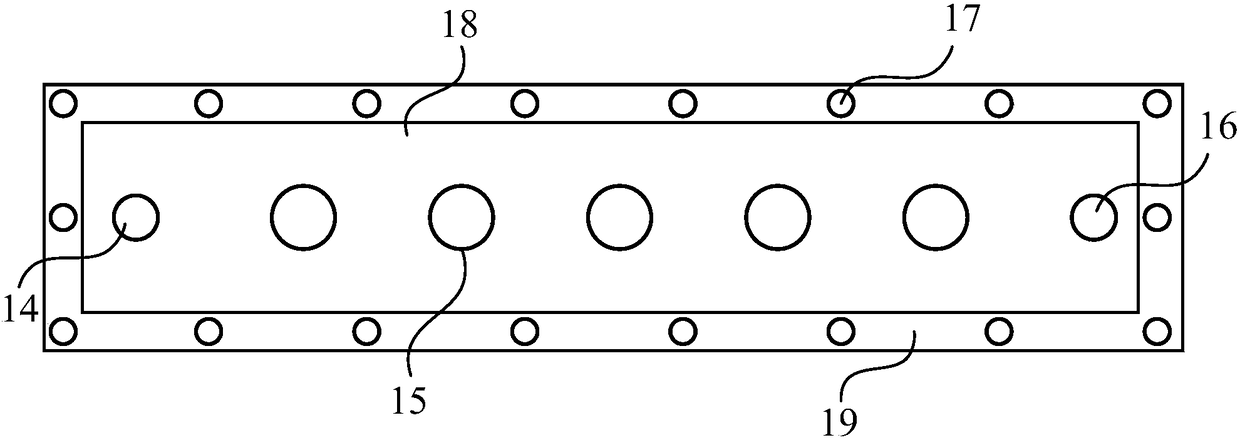

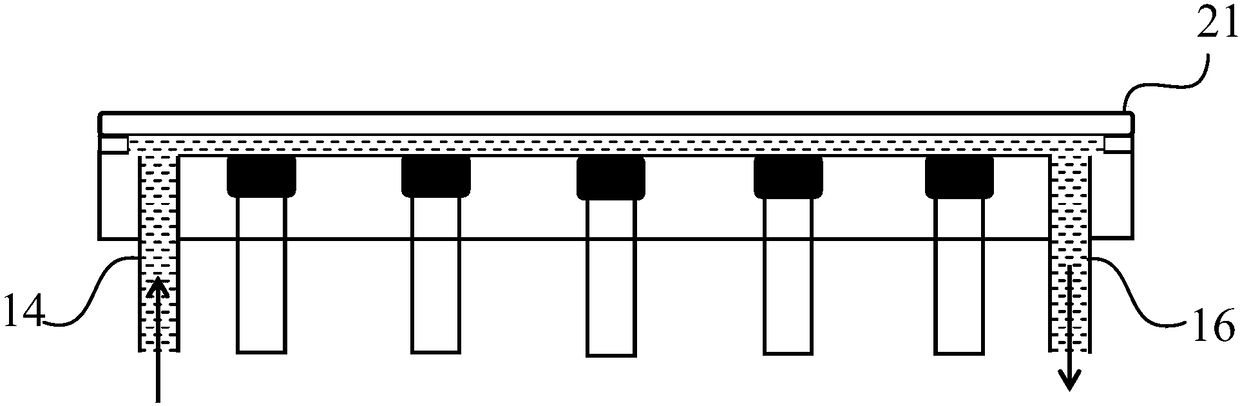

[0048] Step 3, sample installation and medium filling: install the 3 processed samples as a group of parallel samples in the sample installation port of the thin liquid layer flushing channel 1, and add the prepared salt solution to the fluid storage tank 4. , then through CO 2 The gas cylinder 13 slowly injects CO into the fluid storage tank 4 2 Gas, stop the injection when the p...

Embodiment 2

[0052] Corrosion Behavior of Carbon Steel Pipe Lines in Oil and Gas Produced Water at High Flow Rates

[0053] Step 1, sample preparation: the carbon steel pipe section is processed into a smooth sample, the surface of the sample is polished step by step with 200#, 400#, 800# and 1200# sandpaper, and the size of the sample is measured and weighed;

[0054] Step 2, preparation of simulated solution: in parts by mass, 60 parts of NaCl, 20 parts of MgSO 4 , 33 parts of CaCl 2 , 8 parts of NaHCO 3 and 3 servings of KHCO 3 Mix evenly with 10 liters of deionized water to prepare a simulated solution;

[0055] Step 3, sample installation and medium filling: install the 3 processed samples as a group of parallel samples in the sample installation port of the thin liquid layer flushing channel 1, and add the prepared salt solution to the fluid storage tank 4. , then through CO 2 The gas cylinder 13 slowly injects CO into the fluid storage tank 4 2 Gas, stop the injection when the...

Embodiment 3

[0059] Corrosion Behavior of Carbon Steel Pipe Lines in Oil and Gas Produced Water at High Flow Rates

[0060] Step 1, sample preparation: the carbon steel pipe section is processed into a smooth sample, the surface of the sample is polished step by step with 200#, 400#, 800# and 1200# sandpaper, and the size of the sample is measured and weighed;

[0061] Step 2, preparation of simulated solution: in parts by mass, 70 parts of NaCl, 18 parts of MgSO 4 , 39 parts of CaCl 2 , 7 parts of NaHCO 3 and 4 servings of KHCO 3 Mix evenly with 10 liters of deionized water to prepare a simulated solution;

[0062] Step 3, sample installation and medium filling: install the 3 processed samples as a group of parallel samples in the sample installation port of the thin liquid layer flushing channel 1, and add the prepared salt solution to the fluid storage tank 4. , then through CO 2 The gas cylinder 13 slowly injects CO into the fluid storage tank 4 2 Gas, stop the injection when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com