Preparation method of cure-peelable high-viscosity radioactive aerosol inhibitor

A radioactive and aerosol technology, used in the field of nuclear pollution decontamination, can solve problems such as radioactive aerosol pollution, and achieve the effects of safety protection, high viscosity, and prevention of pollution from spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

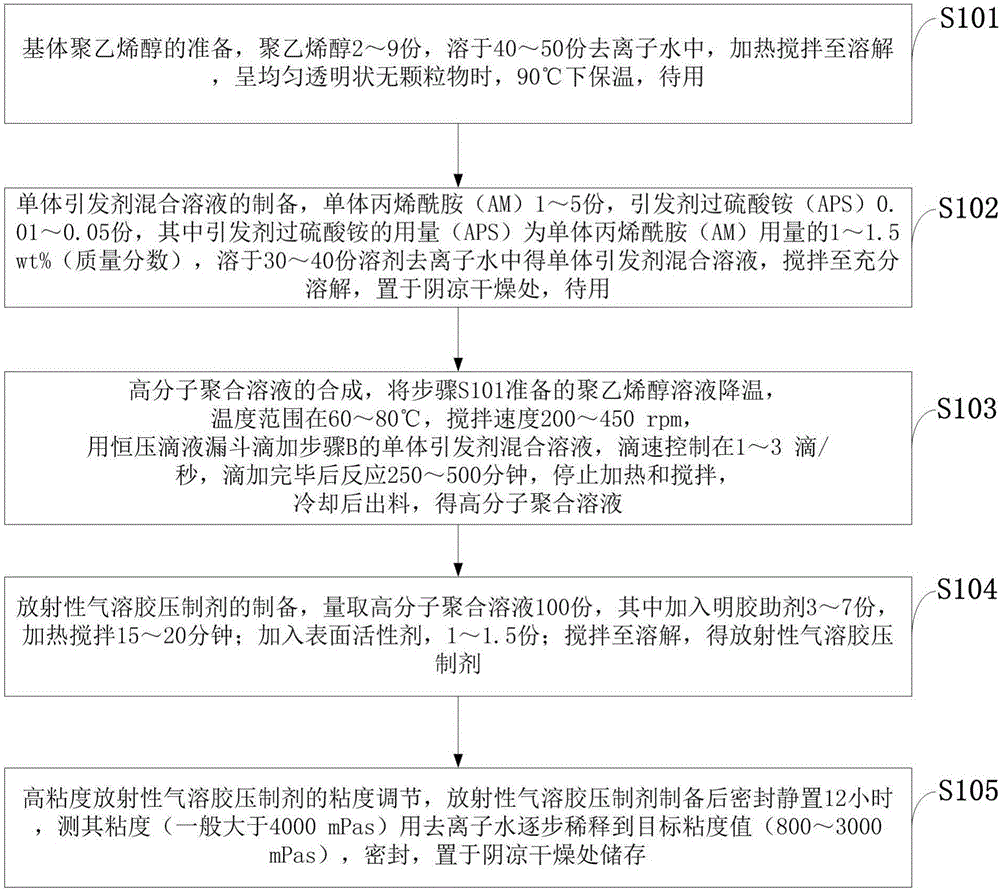

[0020] Such as figure 1 As shown, the preparation method of the curable stripped high-viscosity radioactive aerosol press preparation of the embodiment of the present invention comprises the following steps:

[0021] S101: Preparation of matrix polyvinyl alcohol, 2 to 9 parts of polyvinyl alcohol, dissolved in 40 to 50 parts of deionized water, heated and stirred until dissolved, uniform and transparent without particles, kept at 90°C, and set aside;

[0022] S102: Preparation of monomer initiator mixed solution, monomer acrylamide (AM) 1-5 parts, initiator ammonium persulfate (APS) 0.01-0.05 parts, wherein the amount of initiator ammonium persulfate (APS) is the monomer 1 to 1.5 wt% (mass fraction) of the amount of acrylamide (AM), dissolved in 30 to 40 parts of solvent deionized water to obtain a monomer initiator mixed solution, stirred until fully dissolved, placed in a cool and dry place, and used;

[0023] S103: Synthesis of polymer polymerization solution, cool down th...

Embodiment 1

[0029] 1. Preparation of Polymer Solution

[0030] Put 600g of polyvinyl alcohol (PVA1799) and 2000ml of deionized water in a reactor, raise the temperature to 90°C, stir for 90min until the polyvinyl alcohol is completely dissolved, cool down to 80°C, and keep warm for later use.

[0031] 60 g of acrylamide (AM) monomer and 0.6 g of ammonium persulfate (APS) initiator were dissolved in 1200 ml of deionized water to form a monomer initiator mixed solution, ready for use.

[0032] Add the monomer initiator mixed solution dropwise at a rate of 2 drops / second, and the dropwise addition is completed in 80 minutes. After the monomer initiator mixed solution has been dripped, keep it warm for 200 minutes, cool down and discharge to obtain a polymer polymerization solution.

[0033] 2. Preparation of radioactive aerosol compression preparation

[0034] Measure 1L of the polymer solution, heat to 40°C, add 10g of gelatin, stir for 30 minutes (rotating speed 250-400rpm), cool down to ...

Embodiment 2

[0042] 1. Preparation of matrix polyvinyl alcohol

[0043] Dissolve 2-9 parts of polyvinyl alcohol (PVA1799) in 40-50 parts of deionized water, heat and stir until dissolved, and when it is uniform and transparent without particles, keep warm at 90°C and set aside.

[0044] 2. Preparation of monomer initiator mixed solution

[0045] 1-5 parts of monomer acrylamide (AM), 0.01-0.05 parts of initiator ammonium persulfate (APS), wherein the amount of initiator ammonium persulfate (APS) is 1-1.5wt of the amount of monomer acrylamide (AM) % (mass fraction), dissolved in 30 to 40 parts of solvent deionized water to obtain a monomer initiator mixed solution, stirred until fully dissolved, placed in a cool and dry place, and set aside.

[0046] 3. Synthesis of Polymer Solution

[0047] Cool down the polyvinyl alcohol solution prepared in step 1, the temperature range is 60-80°C, the stirring speed is 200-450rpm, and the monomer initiator mixed solution in step B is added dropwise wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com