Solid-state thin film integrated circuit capacitor having self-repairing effect and fabrication method thereof

An integrated circuit, self-healing technology, applied in the direction of thin film/thick film capacitors, fixed capacitors, fixed capacitor electrodes, etc., can solve the problems of increased energy storage density, low film dielectric constant, etc., to improve service life and low cost of raw materials , The effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

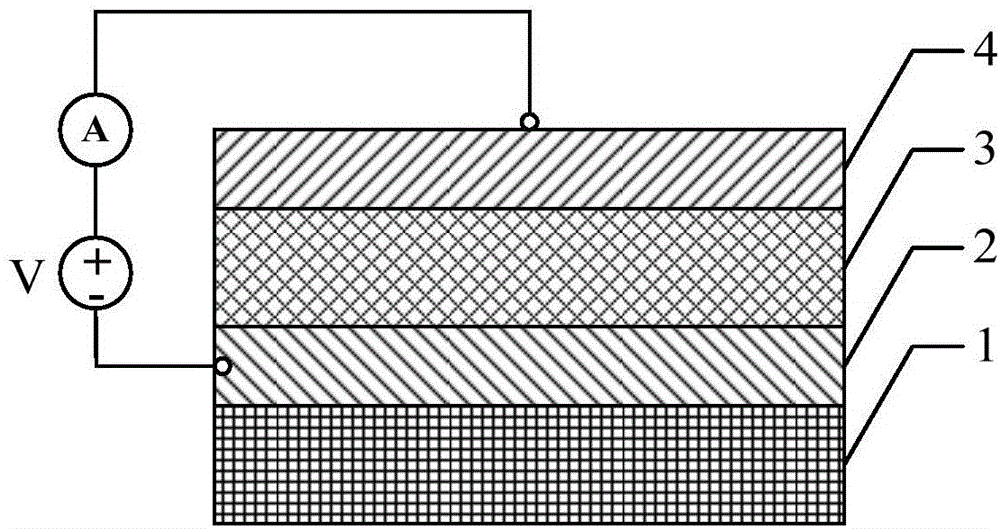

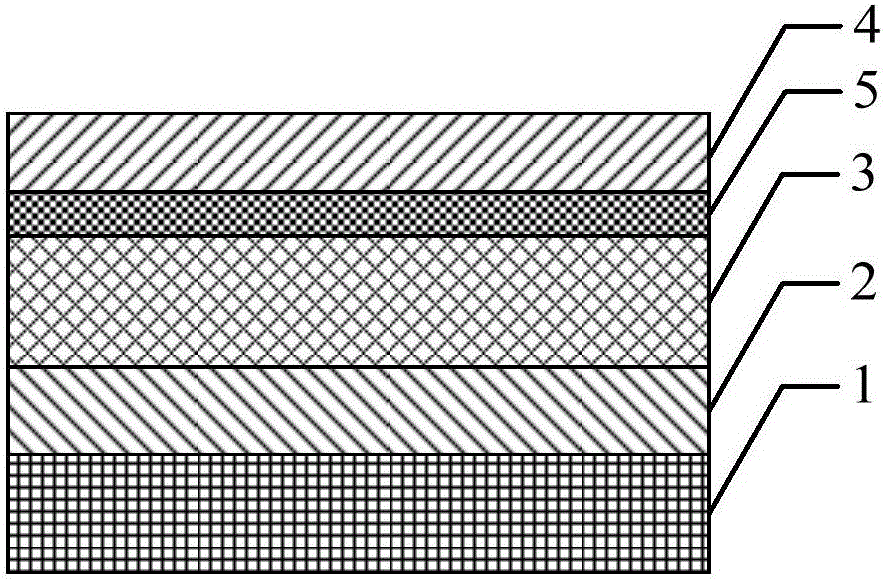

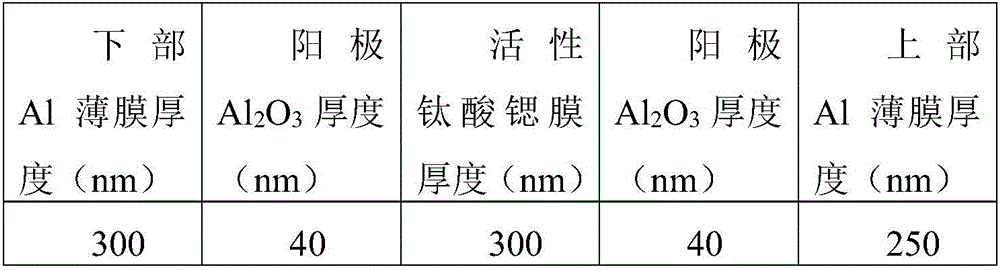

[0049] like figure 1 Shown is a cross-sectional schematic diagram and a schematic circuit diagram of a capacitor unit without electrochemical treatment in the present invention. The capacitor unit includes a silicon wafer 1 (substrate substrate), a lower electrode 2, an active strontium titanate thin film 3 and an Al thin film 4. like figure 2 As shown, it is a schematic cross-sectional view of a capacitor unit after electrochemical treatment in the present invention, and the capacitor unit includes a silicon wafer 1, a lower electrode 2, an active strontium titanate film 3, an Al film 4 and an anode Al 2 o 3 Film 5, the active strontium titanate thin film 3 is arranged between the lower electrode 2 and the Al thin film 4, and the interface between the active strontium titanate thin film 3 and the Al thin film 4 is a layer of anode Al with self-repairing function formed by electrochemical treatment 2 o 3 Film 5. In the process of defect elimination and repair, a voltage g...

Embodiment 2

[0058] In this example, the heat treatment conditions after each coating of the strontium titanate film are 200°C for 5 minutes, 350°C for 5 minutes, 500°C for 5 minutes, 350°C for 5 minutes, and 200°C for 5 minutes to obtain a certain thickness of strontium titanate The thin film was annealed at 450° C. for 3 hours with oxygen, and the conditions of other experimental procedures were the same as those in Example 1.

Embodiment 3

[0060] In this example, the heat treatment conditions after coating the strontium titanate film each time are 200°C for 5 minutes, 500°C for 5 minutes, and 200°C for 5 minutes. After obtaining a certain thickness of strontium titanate film, annealing with oxygen at 500°C for 3 hours , and all the other experimental procedure conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com