Mosfet packaging structure and its manufacturing method

A technology of packaging structure and conductive pad, which is used in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc. The effect of high production efficiency, shortened interconnection distance and excellent heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] As a preferred embodiment, a method for manufacturing a MOSFET packaging structure of the present invention includes the following steps:

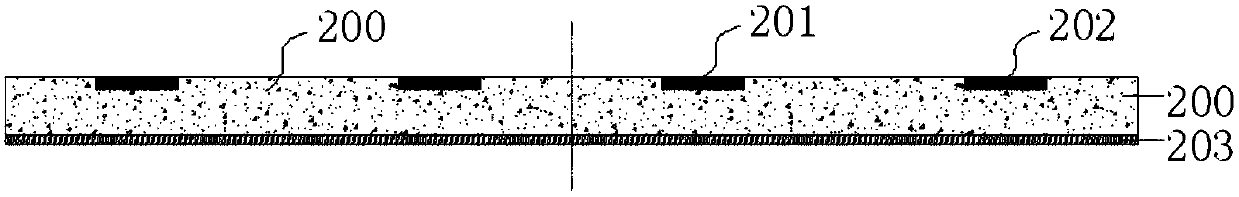

[0053] a. see figure 1 , providing several MOSFET chips 200, the front side of the MOSFET chip includes a source conductive pad 201 and a gate conductive pad 202, and the back side of the MOSFET chip includes a drain region and a metal layer 203 on the drain region, wherein the The gate conductive pad is insulated from the source conductive pad and the drain region;

[0054] During specific implementation, a plurality of MOSFET chips can be cut and separated from a MOSFET wafer.

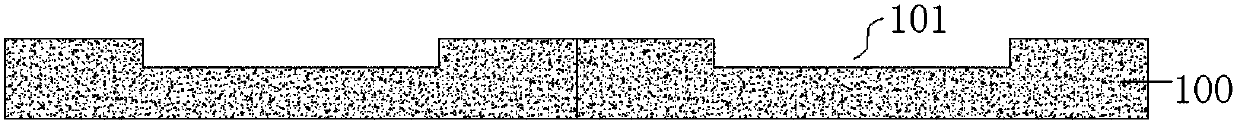

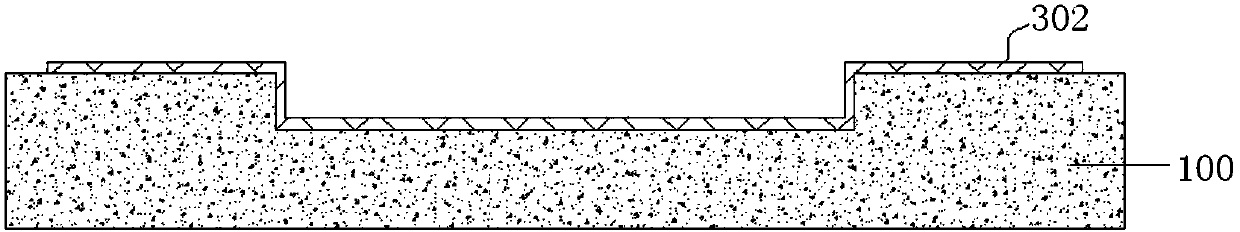

[0055] b. see figure 2 , image 3 and Figure 4 , providing a silicon wafer with a plurality of sunken grooves 101 on the surface, as a silicon substrate 100, plating a conductive layer on the surface of the silicon wafer with sunken grooves, the conductive layer covers the bottom of the sunken grooves, and extends to the surface of the silicon wafer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com