Novel green brick tea manufacturing process

A production process and technology of green brick tea, applied in the directions of tea, tea spices, tea treatment before extraction, etc., can solve the problems of narrowing the promotion scope of green brick tea, green brick tea does not have floral fragrance, complicated operation, etc. The effect of increasing aroma adsorption and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the extraction method of roselle aroma

[0028] After crushing 500.00g of roselle calyx, put it in a 2L barrel, and put it into the extraction kettle, install the pressure ring and sealing ring, tighten the plug, then turn on the freezer, and put the extraction kettle, separation kettle Ⅰ, Adjust the temperature controller of the separation kettle II to the required set temperature; when the temperature of the refrigerator drops to about 0°C, the temperature of the extraction kettle and separation kettle I reaches 55°C, and the temperature of the separation kettle II reaches 40°C, open the gas cylinder and open the Valve 2 (CO 2 Liquefied in the cold cycle), then turn on the high-pressure pump to pressurize, when the extraction pressure of the extraction kettle reaches 20MPa, adjust the shut-off valve to balance the pressure of the extraction kettle, and then adjust the valve to control the pressure of the separation kettle I and the separation kettle II o...

Embodiment 2

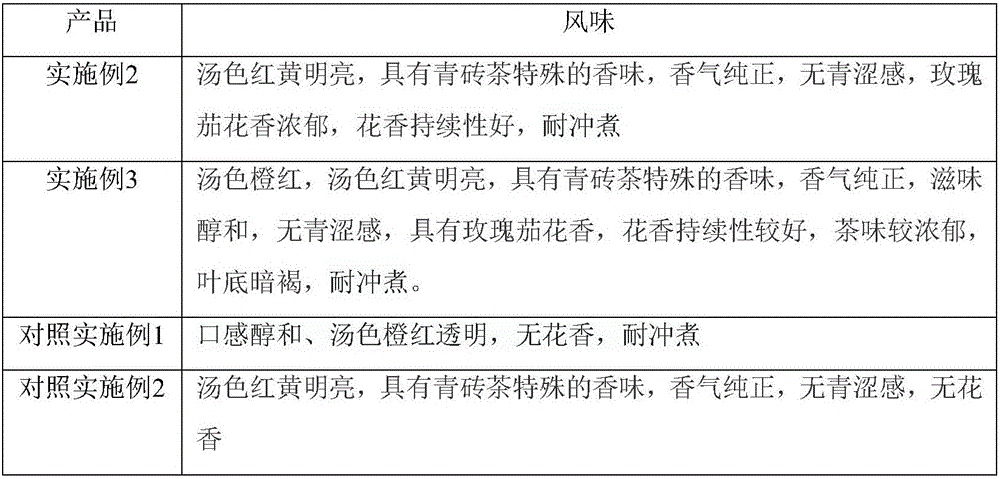

[0029] Embodiment 2: the making of a kind of flower-flavored green brick tea

[0030]Weigh 100Kg of dry Hei Mao tea leaves, spray 10kg of water with a sprayer, control the moisture content to 15-25%, pile them into a pile of tea, the height of the pile is about 40cm, cover with wet cotton cloth, control the temperature at 75-85℃, The relative humidity is controlled at 75-85%, piled up for 8 hours, and steamed with 110°C steam for 20 minutes. After the steamed Hei Maocha is cooled, 2kg of S. coronoides spore powder is evenly sprayed on the sterilized Hei Maocha. And control its water content at about 25%, temperature at 28-30°C, relative air humidity at 85%, and flowering time of 18 hours, so that the black hair tea can fully flower; take 10Kg of fermented tea and place it in an airtight Spread out evenly on the upper layer of the container, place 0.2L roselle concentrate on the lower layer, heat the roselle concentrate, and control the temperature at 100°C to fully release the...

Embodiment 3

[0031] Embodiment 3: the making of a kind of Luzhou-flavor green brick tea

[0032] Weigh 100Kg of dry Hei Mao tea leaves, spray 10kg of water with a sprayer, control the moisture content to 15-25%, pile them into a pile of tea, the height of the pile is about 40cm, cover with wet cotton cloth, control the temperature at 75-85℃, The relative humidity is controlled at 75-85%, piled up for 8 hours, and steamed with 110°C steam for 20 minutes. After the steamed Hei Maocha is cooled, 2kg of S. coronoides spore powder is evenly sprayed on the sterilized Hei Maocha. And control its water content at about 25%, temperature at 28-30°C, relative air humidity at 85%, and flowering time of 18 hours, so that the black hair tea can fully flower; take 10Kg of fermented tea and place it in an airtight Spread out evenly on the upper layer of the container, place 0.2L roselle concentrate on the lower layer, heat the roselle concentrate, and control the temperature at 100°C to fully release the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com