An energy-saving wet desulfurization device and process method

A technology of wet desulfurization and process method, applied in the field of coal chemical industry, can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

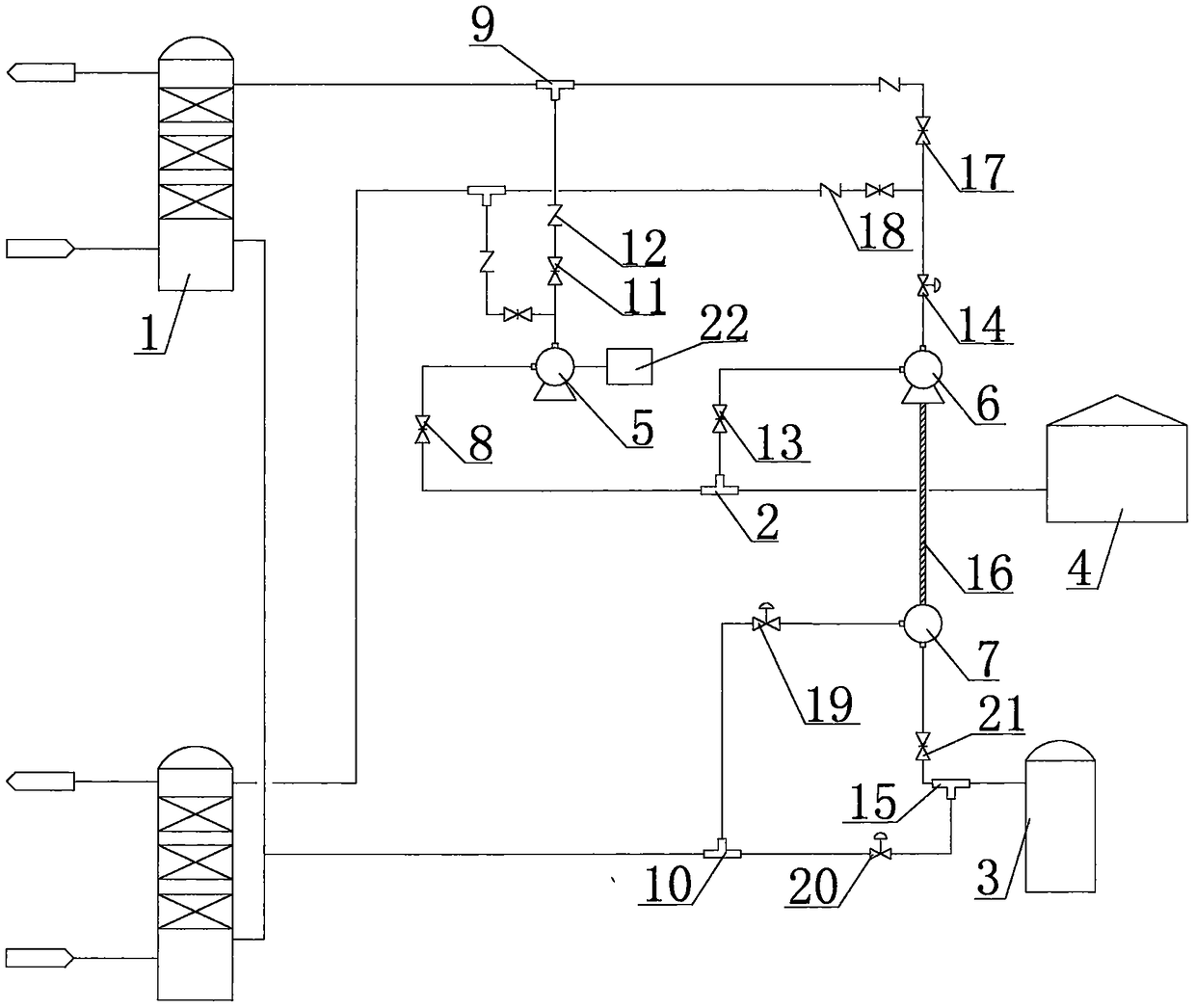

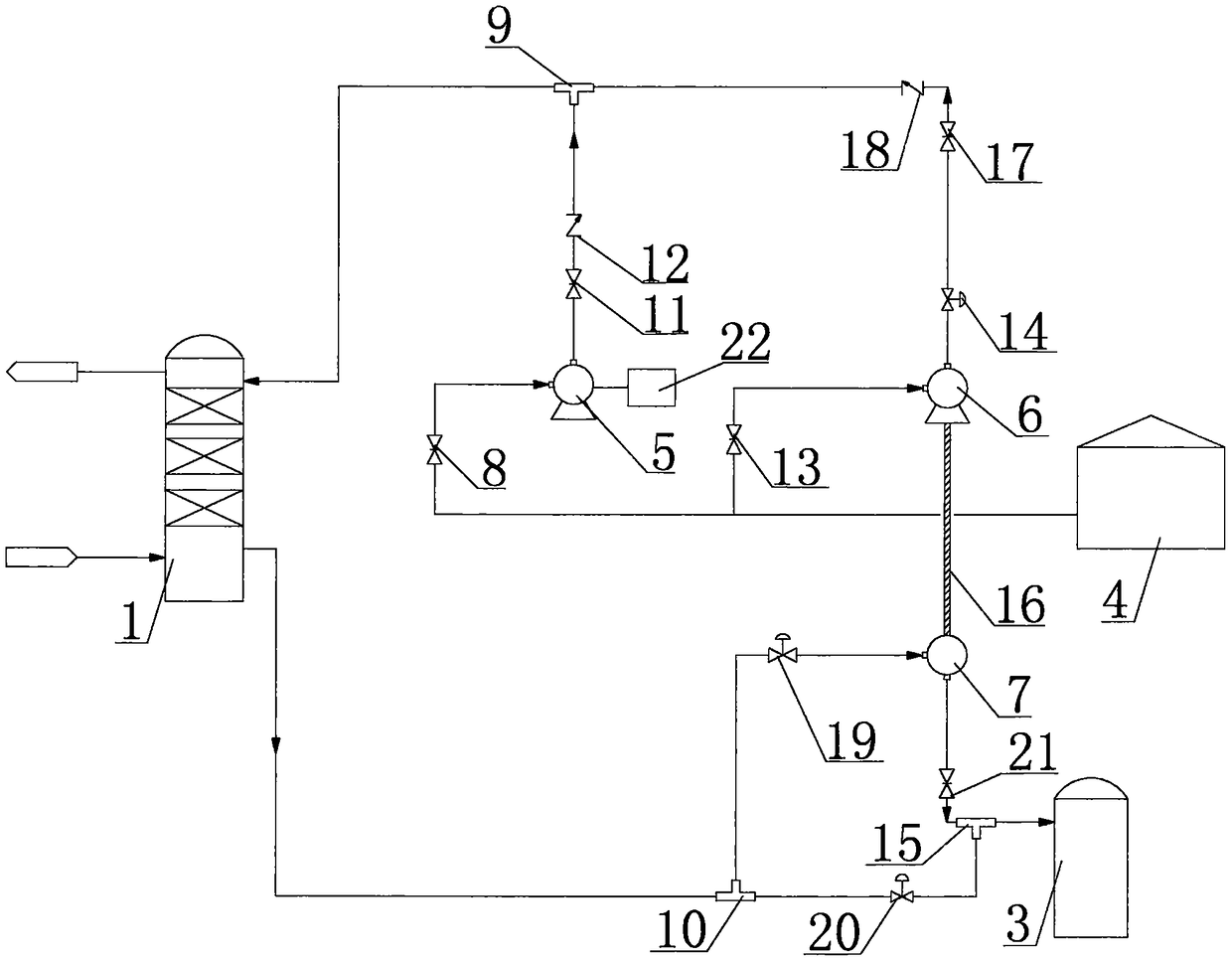

Image

Examples

Embodiment 1

[0029] A process method of an energy-saving wet desulfurization device, comprising the following steps:

[0030] Step 1: The desulfurized lean liquid in the lean liquid tank 4 is divided into two parts, one part enters several desulfurization towers 1 through the energy recovery unit, and the other part enters several desulfurization towers 1 through the energy replenishment unit; the desulfurization lean liquid The liquid components are sodium carbonate, sodium metavanadate, baking gel and water, and the temperature of the desulfurized poor liquid is 30°C;

[0031] Step 2: When the desulfurized lean liquid in the energy recovery unit and the energy replenishment unit enters the desulfurization tower 1 and contacts the shift gas countercurrently, absorbs the hydrogen sulfide in the shift gas to become a desulfurization rich liquid; the desulfurization rich liquid passes through the desulfurization tower 1 The pressure behind the bottom liquid outlet is 1.5MPa;

[0032] Step 3...

Embodiment 2

[0034] A process method of an energy-saving wet desulfurization device, comprising the following steps:

[0035] Step 1: The desulfurized lean liquid in the lean liquid tank 4 is divided into two parts, one part enters several desulfurization towers 1 through the energy recovery unit, and the other part enters several desulfurization towers 1 through the energy replenishment unit; the desulfurization lean liquid The liquid components are sodium carbonate, sodium metavanadate, baking gel and water, and the temperature of the desulfurized poor liquid is 50°C;

[0036] Step 2: When the desulfurized lean liquid in the energy recovery unit and the energy replenishment unit enters the desulfurization tower 1 and contacts the shift gas countercurrently, absorbs the hydrogen sulfide in the shift gas to become a desulfurization rich liquid; the desulfurization rich liquid passes through the desulfurization tower 1 The pressure behind the bottom liquid outlet is 2.4MPa;

[0037] Step 3...

Embodiment 3

[0039] A process method of an energy-saving wet desulfurization device, comprising the following steps:

[0040] Step 1: The desulfurized lean liquid in the lean liquid tank 4 is divided into two parts, one part enters several desulfurization towers 1 through the energy recovery unit, and the other part enters several desulfurization towers 1 through the energy replenishment unit; the desulfurization lean liquid The liquid components are sodium carbonate, sodium metavanadate, baking gel and water, and the temperature of the desulfurized poor liquid is 40°C;

[0041] Step 2: When the desulfurized lean liquid in the energy recovery unit and the energy replenishment unit enters the desulfurization tower 1 and contacts the shift gas countercurrently, absorbs the hydrogen sulfide in the shift gas to become a desulfurization rich liquid; the desulfurization rich liquid passes through the desulfurization tower 1 The pressure behind the bottom liquid outlet is 1.95MPa;

[0042] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com