High-hardness high-conductivity cooper-carbon composite and preparation method and application thereof

A high-conductivity, composite material technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of the volume fraction limit of the reinforcement, the inability to apply it on a large scale, and reduce the conductivity of copper. Low cost, increased hardness, and small reduction in electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

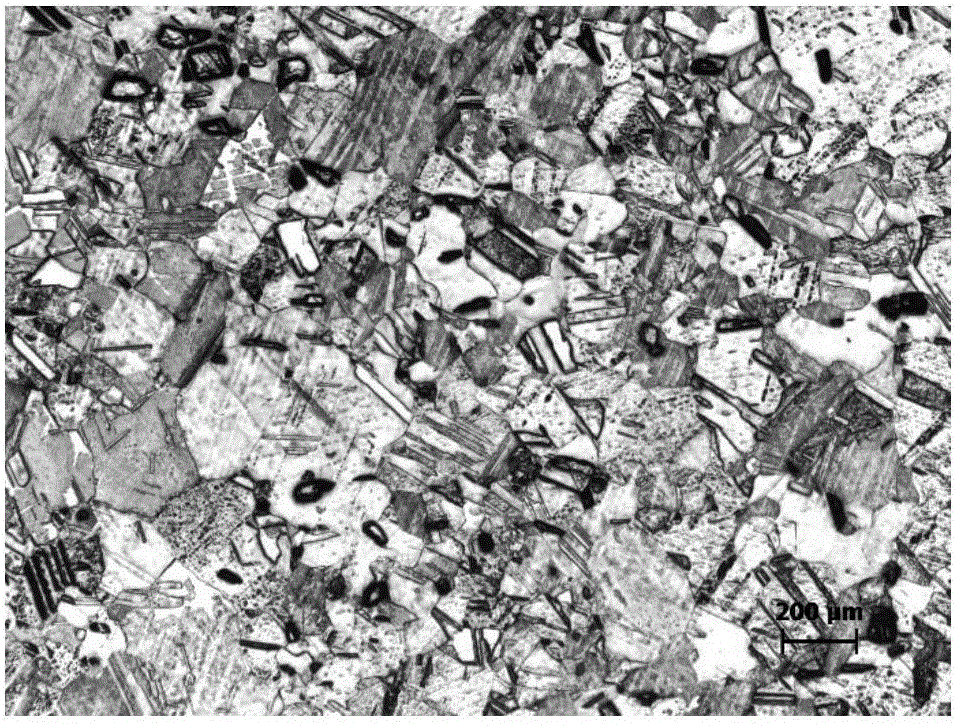

Embodiment 1

[0035] In this embodiment, the grade of the copper plate is TU1, and its size is 100 mm in length, 10 mm in width, and 1 mm in thickness. The copper plate is heat-treated at 600°C in an argon protective atmosphere in advance, annealed after 2 hours, and the surface treatment such as deoxidizing film and degreasing is carried out on the fully annealed copper plate. The graphite powder is spread on the copper plate, and the graphite powder volume accounts for 0.1% of the volume of the whole composite material (copper+graphite). The graphite powder evenly covers the upper surface of half of the copper plate, and the copper plate is centered and bent to enclose the graphite powder. The folds are pressed and then rolled at room temperature without lubrication. Repeat the above procedure (surface treatment is carried out to the rolled copper plate, no longer add graphite powder, fold in half along the rolling direction, and then roll). The graphite powder has a purity of 99% and a ...

Embodiment 2

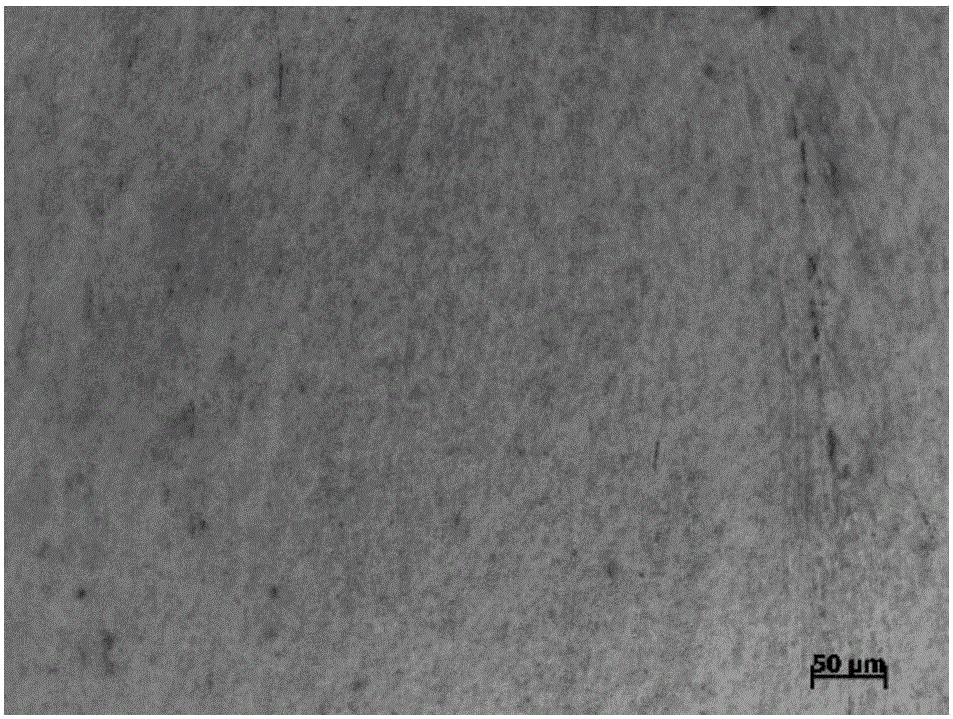

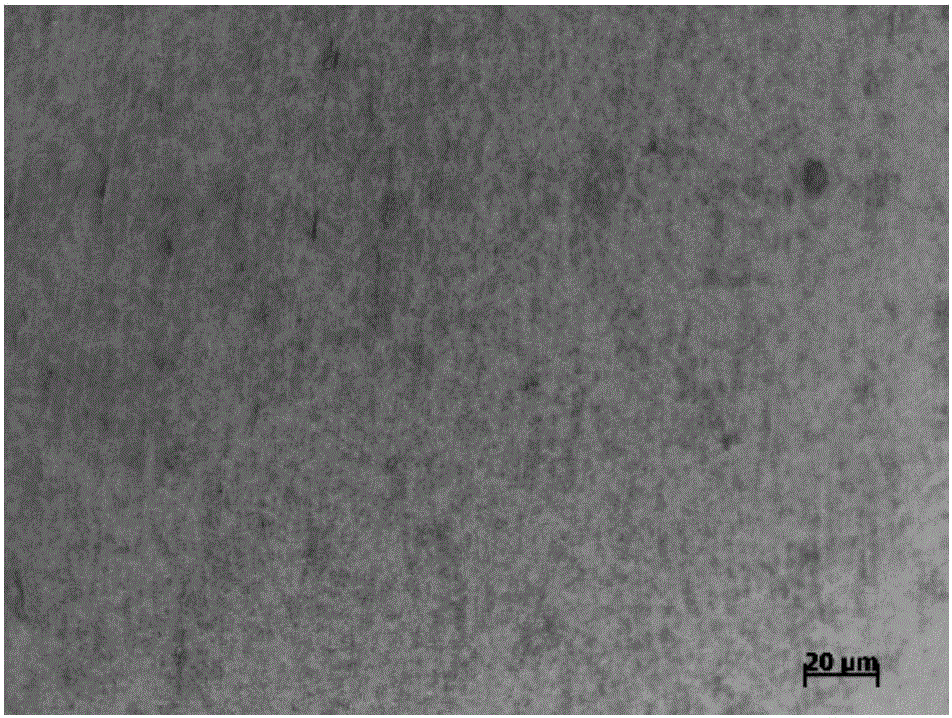

[0042]The graphite powder is sandwiched between pure copper copper plates that have been completely annealed, deoxidized, and degreased. The volume of the graphite powder accounts for 0.1% of the volume of the entire composite material (copper + graphite), and then it is used at room temperature without lubrication. The same process as in Example 1 was carried out continuously for 30 passes of cumulative rolling.

[0043] In this embodiment, the grade of the copper plate is TU1, and its size is 100 mm in length, 10 mm in width, and 1 mm in thickness. The copper plate is heat-treated at 600°C in an argon protective atmosphere in advance, annealed after 2 hours, and the surface treatment such as deoxidizing film and degreasing is carried out on the fully annealed copper plate. The purity of graphite powder is 99%, and the particle size is about 48 μm. Adopt industrial rolling mill, rolling speed is 187mm / min. During each rolling pass, the reduction in the thickness direction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com