Induction-ultrasound combination assisted laser metal forming method

A metal forming and assisted laser technology, which is applied in the field of induction-ultrasonic composite assisted laser metal forming and high-performance metal forming parts, can solve the problems of unsatisfactory real-time preheating effect, reduced service life, weakened vibration effect, etc., and achieve heat dissipation effect Better, prolong the action time, slow down the effect of setting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

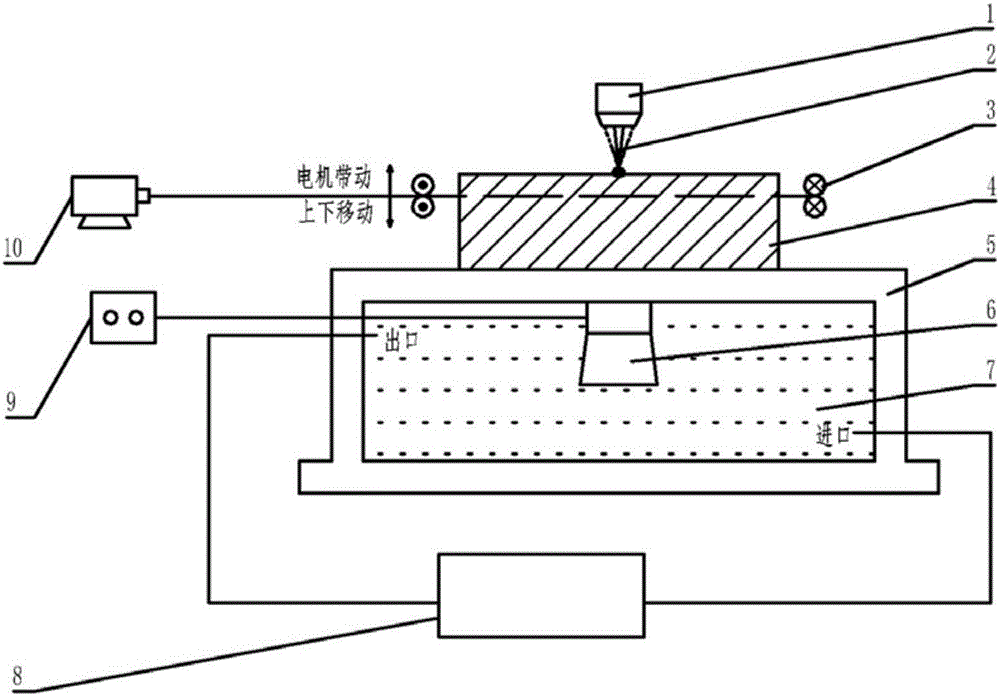

[0018] The specific implementation manner of the present invention will be further described below according to the technical scheme and the accompanying drawings.

[0019] refer to figure 1 As shown, the ultrasonic transducer 6 is connected to the ultrasonic stage 5. When the ultrasonic generator 9 drives the ultrasonic transducer 6 to work, driven by the ultrasonic transducer cooling system 8, the transformer oil 7 is imported from the cooling pipe. Enter the ultrasonic stage and flow out from the outlet of the cooling pipe and then flow back to the ultrasonic transducer cooling system 8 to circulate and cool the ultrasonic transducer 6; the matrix 4 is rigidly connected to the ultrasonic stage 5, when the laser metal forming system is turned on , the metal powder sent by the coaxial powder feeding nozzle 1 is melted under the irradiation of the high-energy laser beam 2 and forms a molten pool on the substrate, and the induction coil 3 moves in real time with the growth of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com