Preparation method of integral cast-in-site arresting bed and capturing material of arresting bed

An integral, cast-in-place technology, applied to ceramic products, other household utensils, applications, etc., can solve the problems of easy damage, transportation and installation costs, and achieve the effects of easy transportation, simple preparation process, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

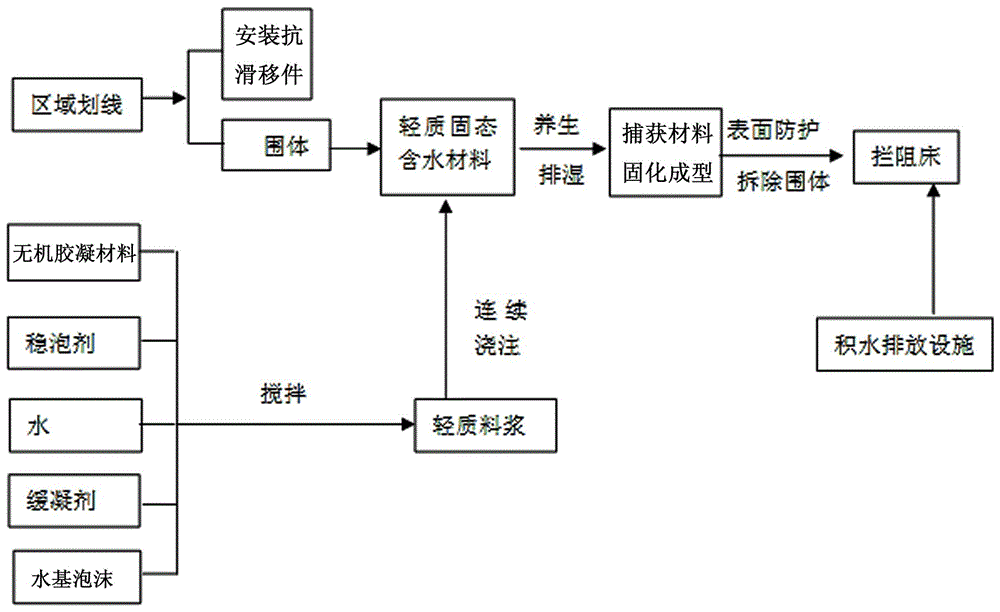

[0052] Such as figure 1 As shown, a method for preparing an integral cast-in-place arresting bed and its capture material includes the following steps:

[0053] A) Install anti-slip components: According to the design requirements, fix the plastic anti-slip anchors perpendicular to the road surface and consistent with the height of the arresting bed with epoxy resin at certain intervals in the set position of the arresting bed;

[0054] B). Enclosure construction: In accordance with the design requirements, use construction wooden template to build the arresting bed to pour the enclosure, and seal and strengthen the joints;

[0055] C) Preparation of slurry: mix 180 parts by weight of sulphoaluminate cement, 5 parts by weight of calcium stearate, 50 parts by weight of water, and 0.5 parts by weight of sodium citrate, put them into a mixer for stirring, and then add gas-containing water Based on foam, quickly stir uniformly and make it uniformly prepared into a light slurry with certa...

Embodiment 2

[0066] Such as figure 1 As shown, a method for preparing an integral cast-in-place arresting bed and its capture material includes the following steps:

[0067] A) Pre-embedded anti-slip parts: According to the design requirements, at a certain interval within the set position of the arresting bed, pre-embedding the plastic anti-slip net frame perpendicular to the road surface and consistent with the height of the arresting bed;

[0068] B). Enclosure construction: According to the design requirements, use the plastic template for construction to build the barrier bed to pour the enclosure, and use the internal butter joint to seal it;

[0069] C) Preparation of slurry: mix 100 parts by weight of overfire lime, 100 parts by weight of powdered slaked lime (also called slaked lime), 4 parts by weight of silicone resin polyether emulsion, 55 parts by weight of water and 0.5 parts by weight of sodium citrate , Into the mixer for stirring, and then add the gas-containing water-based foam,...

Embodiment 3

[0078] Such as figure 1 As shown, a method for preparing an integral cast-in-place arresting bed and its capture material includes the following steps:

[0079] A) Install anti-slip parts: According to the design requirements, fix the plastic anti-slip grid perpendicular to the road surface and the same height as the arresting bed with epoxy resin at a certain interval in the set position of the arresting bed;

[0080] B). Enclosure construction: According to the design requirements, use templates to build a non-leaking barrier bed for pouring enclosure;

[0081] C) Preparation of slurry: mix 180 parts by weight of sulphoaluminate cement, 4 parts by weight of calcium stearate, 58 parts by weight of water, and 1 part by weight of sodium polyphosphate, put them into a mixer for stirring, and then add gas-containing Water-based foam, quickly stir evenly and make it evenly prepared into a light slurry with certain fluidity;

[0082] D) Pouring: The lightweight slurry prepared in step C) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com